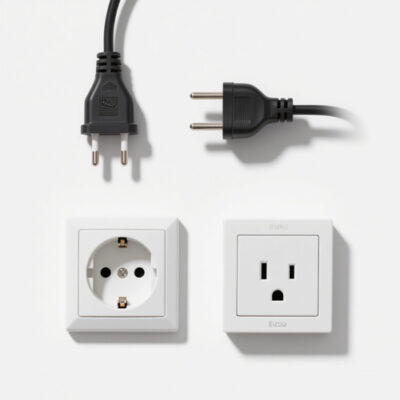

LISUN’s plugs and sockets test solutions are designed to ensure compliance with key international standards, providing comprehensive support for testing the safety, electrical, and mechanical performance of various products. These include household and similar plugs and sockets (IEC 60884-1:2022), which covers critical tests such as protection against electric shock, temperature rise, and mechanical strength; enclosures for electrical accessories (IEC 60670-1:2021), specifying requirements for insulation resistance, aging resistance, and ingress protection; high-voltage shore connection system plugs and couplers (IEC 62613-1:2019), focusing on torque testing, temperature rise, and corrosion resistance; plugs with arcuate contacts (IEC 62986:2017), emphasizing earthing provisions and impact resistance; and DC plugs for data centers (IEC TS 62735-1:2015), with tests for creepage distance and rust resistance.

LISUN’s plugs and sockets test solutions encompass all key test items outlined in the above standards, equipped with a full range of professional testing equipment to meet diverse needs. This includes electrical performance tests (insulation resistance, dielectric strength, temperature rise), mechanical performance tests (insertion/extraction force, bending, impact resistance), safety tests (protection against electric shock, glow-wire test, resistance to tracking), and environmental adaptability tests (aging resistance, humidity resistance, salt spray corrosion). By offering one-stop testing support, we help manufacturers and laboratories verify that plugs and sockets meet international standards, ensuring their safe and reliable operation in household, industrial, and data center applications.

Plug Socket Test Solutions

Standard:

LISUN Plugs and Sockets Test solution fully meet the follow standard:

IEC 60884-1 Plugs and socket-outlets for household and similar purposes – Part 1: General requirements.pdf-download

LISUN supplies the fully test solutions for the following IEC 60884-1:2022, please see the below excel table:

| IEC 60884-1:2022 Clause and Subject | LISUN Model |

| Clause 10.1.1 test probe 12 | SMT-1212 |

| Clause10.2 Accessibility of live parts during normal use | SMT-02T10 and SMT-1175 |

| Clause 10.3.1 (Figure 2a – Apparatus for Mechanical strength test on resilient covers) | GNGPL-3602 |

| Clause10.5 Shuttered socket-outlets | SMT-CZ12 |

| Clause 11.5 Internal connection with the earthing terminal | LSP-5KVAS |

| Clause 12.3.11 Contact Pressure Drop Test Device | JCY-1 |

| Clause 12.3.12 Figure 14 IEC 60884.1 IEC 60669-1 Clause 12.3.12 Screwless Terminals Bending Test Device | JCY-2 |

| Clause 13.14 Lateral strain imposed by equipment(Figure 16) | BCL-1 |

| Clause 13.2 (Figure 4a)BS1363 of British Standard Plugs Socket Outlets Gauges | GNGPL-3604 |

| Clause 13.6.1 Apparatus for testing plug cover fixing screws(Figure 6) | GNGPL-3606 |

| Clause 13.6.1 Test pin (Figure 1) | SMT-BS01 |

| Clause 13.9.4.1 Apparatus for tests on plug pins (Figure 32a) | GNGPL-3632 |

| Clause 13.9.6.1 Apparatus for torsion test on pins (Figure 33) | GNGPL-3633 |

| Clause 13.11.1 Mounting plate (Figure 7) | GNGPL-3607 |

| Clause 13.12 Plug pin deflection test apparatus for resilient plugs (Figure 8) | GNGPL-3608 |

| Clause 13.17.3 Apparatus for abrasion test on insulating sleeves of plug pins (Figure 9) | LS-B10 |

| Clause 13.17.4 Apparatus for pressure test at high temperature (Figure 10) | GNGPL-3610 |

| Clause 14.2 Mechanical strength of pins of portable accessories(Figure 17) | LS-B04 |

| Clause 14.22.2 Plug Torque Tester | LSPTT-1 |

| Claue 15 Resistance to ageing and to humidity | GDJS-010A |

| Clause 16.1.2 Insulation resistance | WB2681A |

| Clause 16.2 Protection provided by enclosures(Figure 18) | LS-B05 |

| Clasue 17 Temperatur rise (Figure 17a/17b) | GNGPL-3617 |

| Clause 17.3 Electric strength test | WB2673C |

| Clause 19 Temperature rise | WS-1 |

| Clause 20 Breaking capacity(Figure 22) | CZKS-3 and DFX-20 |

| Clasue 20.1.2 Solid link for test on fuse clips (Figure 19) | GNGPL-3619 |

| Clause 22 (Figure 18 &19)IEC 60884-1 Clause 13.14 Figure 16 Device for Checking the Resistance to Lateral Strain | IEC 60884-1 Clause 20 Figure 18 and 19 Maximum and Minimum Pull-out Force | BCL-1 |

| Clause 23.1.2 Heating cabinet | GW-225 |

| Clasue 23.1.3 Apparatus for pressure test (Figure 23) | GNGPL-3623 |

| Clause 23.2 Cord anchorage(Figure 27) | LS-B07 and LS-B47 |

| Clause 23.4 Protection of cable entrance in the accessories(Figure 28) | SW-6 and DFX-20 |

| Clause 24.2 Impact test with pendulum hammer | IK01-06P |

| Clause 24.3 Tumble barrel test | LS-DDT1-B |

| Clause 24.5Impact test at low temperature(Figure 30) | DWC-2 |

| Clause 24.6 Compression test(Figure 6) | LS-B08 |

| Clause 24.7 Torque test for cable glands | LWMF-1 |

| Claues 24.8Abrasion test on insulating sleeves of plug pins(Figure 31) | LS-B10 |

| Clause 24.10 Test for multiple portable socket-outlets(Figure 32) | LS-B11 |

| Clause 24.11 Retention test for pins(Figure 33) | LS-B12 |

| Clause 24.12 Mechanical test for means for suspension of portable socket-outlets | SMT-2126 |

| Clause 24.13-15 Tests on covers, cover-plates or parts of them(Figure 34) | LS-B14 |

| Clause 24.16 Verification of the outline of covers fixed without screws on a mounting surface or supporting surface(Figure 35) | GNGPL-23507 |

| Clause 24.17 Verification of grooves, holes and reverse tapers(Figure 38) | SMT-1203 |

| Clause 25.3 Ball-pressure test at 125°℃(Figure 40) | ZBP-T and GW-225 |

| Clause 25.5 Compression test(Figure 41) | LS-TCT-1 |

| Clause 27 Creepage distances, clearances and distances through sealing compound(Table 26) | CK-1 |

| Clause 28.1.2 Glow-wire test | ZRS-3H |

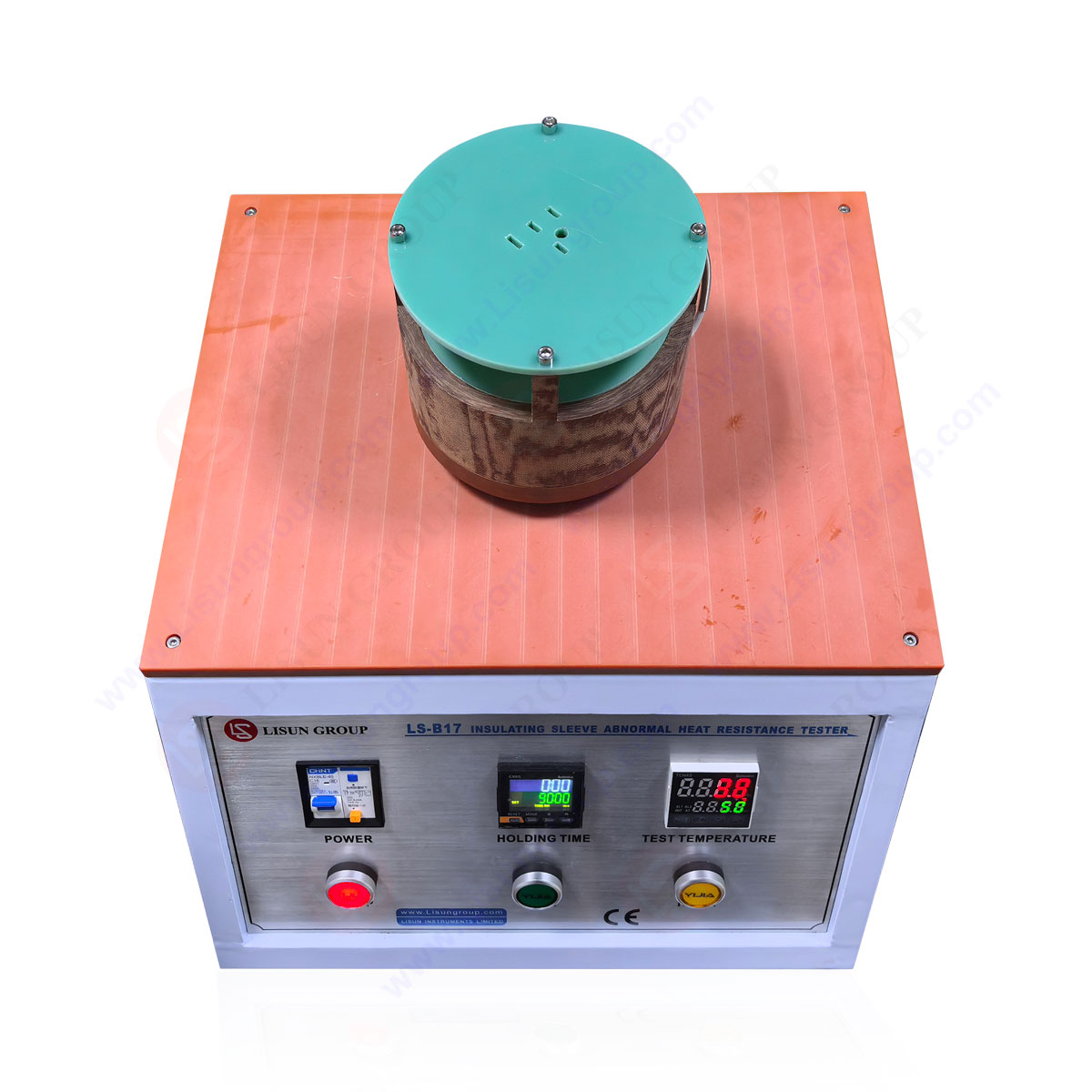

| Clause 28.1.3 Test for pins with insulating sleeves(Figure 43) | LS-B17 |

| Clause 28.2 Resistance to tracking | TTC-1 |

| Clause 29 Resistance to rusting | YWX/Q-010 |

IEC 60670-1 Edition 2.0 Boxes and enclosures for electrical accessories for household and similar fixed electrical installations–Part 1 General requirements

LISUN supplies the fully test solutions for the following IEC 60670-1:2021, please see the below excel table:

| IEC 60670-1:2021 Clause and Subject | LISUN Model |

| Clause 10 Peoduction against electric shock | SMT-1175 |

| Clause 12.1.2 Non-screw type fixing operable without the use of a tool or a key | SMT-02T10 |

| Clause 12.2.3.4Verification of the outline of lids, covers and cover-plates(Figure 6) | GNGPL-23507 |

| Clause 12.2.3.5Verification of grooves, holes and reverse tapers(Figure 9) | SMT-1203 |

| Clause 12.6 (table 3) Boxes and enclosures with inlets for applications other than flexible cables | LNSYJ-1 |

| Clause 13.1 Resistance to ageing | GW-225 |

| Clause 13.2 Protection against the ingress of solid objects | SC-500 |

| Clause 13.3.2 Protection against harmful ingress of water | JL-34 |

| Clause 14.2 Insulation Resistance | WB2681A |

| Clause 14.3 (table 6) Electric strength | WB2673C |

| Clause 15.1 Impact test at low temperature(figure 8) | DWC-2 and GDJW-500B |

| Clause 15.3 & 15.5 Compression test | LS-B21 |

| Clause 15.4 Impact test for boxes and enclosures (figure 7 and figure 9, figure 10) | IK01-06P |

| Clause 16.1 parts of insulating material necessary to retain current -carrying parts | ZBP-T and GW-225 |

| Clause 14 Creepage distances | CK-1 |

| Clause 18 Resistance of insulating material to abnormal heat and fire | ZRS-3H |

| Clause 19 Resistance to tracking | TTC-1 |

| Clause 20 Resistance to corrosion | YWX/Q-010 |

LISUN supplies the fully test solutions for the following IEC 62613-1:2019, please see the below excel table:

| IEC 62613-1:2019 Caluse and Subject | LISUN MODEL |

| Clause 9 Protection against electric shock | SMT-02T50 |

| Clause 10 Provisionsfor protective earthing | WB2678A |

| Clause 11.3.1 flexing tests for copper conductors | JCY-2 |

| Clause 11.3.2 pull-out tests for copper conductors | PULL-2000KG |

| Clause 13 Resistance to ageing of rubber and thermoplastic material | GW-500 |

| Clause 18.2 torque Test | LS-B47 |

| Clause 22.2 torque test | |

| Clause 18.4 proofed against humid conditions | GDJS-015B |

| Clause Insulation resistance measurement | WB2681A |

| Clause 21 Temperature rise | WS-1 |

| Clause 23 Impact resistance/Drop test | LS-B33 |

| Clause 25.1-25.3 Resistance to heat | ZBP-T |

| GW-500 | |

| Clause 25.4 Glow wire test | ZRS-3H |

| Clause 26 Corrosion and resistance to rusting | YWX/Q-010 |

Part 4 IEC 62986:2017 Plugs, socket-outlets and couplers with arcuate contacts

LISUN supplies the fully test solutions for the following IEC 62986:2017, please see the below excel table:

| IEC 62986:2017 Clause and Subject | LISUN MODEL |

| Clause 8.3 Socket outlet with 75N force | SMT-1175 |

| Clause 9 Protection against electric shock | SMT-PB |

| Clause 10 Provisions for earthing | WB2678A |

| Clause 11.3.1 flexing test apparatus | JCY-2 |

| Clause 11.3.2 Pulling force | LNSYJ-1 |

| Clause 12 Resistance to ageing of rubber and thermoplastic material | GDJS-015B |

| Clause 17.3 humidity cabinet | |

| Clause 17 IP20 Degrees of protection | SC-015 |

| Clause 18 Insulation resistance and dielectric strength | WB2681A |

| Clause 21 Temperature rise | WS-1 |

| Clause 22.3 Pull test | LS-B47 |

| Clause 24.1 Torque test | |

| Clause 23.2 Impact test apparatus | IK07-10VT |

| Clause 23.7 flexing test(Figure 13) | SW-6 |

| Clause 25 Creepage distances, clearances and distances through sealing compound | CK-1 |

| Clause 26 Resistance to heat | ZBP-T |

| GW-500 | |

| Claue 27 Resistance to fire | ZRS-3H |

| Clause 28 Corrosion and resistance to rusting | YWX/Q-010 |

LISUN supplies the fully test solutions for the following IEC TS 62735-1:2015, please see the below excel table:

| IEC TS 62735-1:2015 Clause and Subject | LISUN MODEL |

| Clause 10.2 Protection against electric shock | SMT-PB |

| SMT-1150 | |

| GW-500 | |

| LS-B08 | |

| Clause 10.3 Creepage Distance | CK-1 |

| Clause 27 Creepage distances, clearances and distances through sealing compound | |

| Clause 10.5-10.7 Gauge for checking non-accessibility of live parts, | SMT-20N |

| SMT-1N | |

| Clause 11.2 Resistant to corrosion | YWX/Q-010 |

| Clause 12.2.10 corrosion | |

| Clause 29 Resistance to rusting | |

| Clause 11.4 Earthing Resistance | WB2678A |

| Clause 12.2.5 torque test | LS-B47 |

| Table 4 and Table 18 | |

| Clause 12.2.5 damage to the conductor | WDT-1 |

| Clause 12.2.6 Table 2 Pull test | LNSYJ-1 |

| Clause 12.2.5 Insulation resistance measurement | JCY-2 |

| Clause 12.3.12 deflecting stress | |

| Clause 13.19 Heating Cabniet | GW-500 |

| Clause 25 Resistance to heat | |

| Clause 16.1 Resistance to ageing | GDJS-015B |

| Clause 16.3 Resistance to humidity | |

| Clause 17 Insulation resistance and electric strength | WB2681A |

| Clause 19 Temperature rise | WS-1 |

| Clause 22 Force necessary to withdraw the plug | BCL-1 |

| Clause 23.2 The effectiveness of the retention of the cable(Figure 17) | LS-B07 |

| Clause 23.4 Felxing test(Figure 18) | SW-6 |

| Clause impact-test apparatus(Figure 19) | IK07-10VT |

| Clause 24.5 Impact test in a freezer(Figure 20) | DWC-1 |

Your email address will not be published. Required fields are marked *