Product No: SMT-02T10

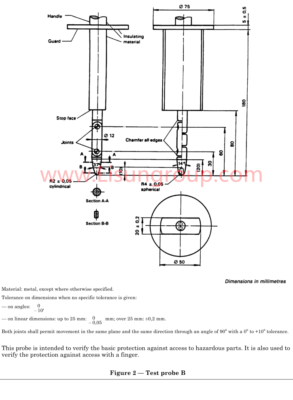

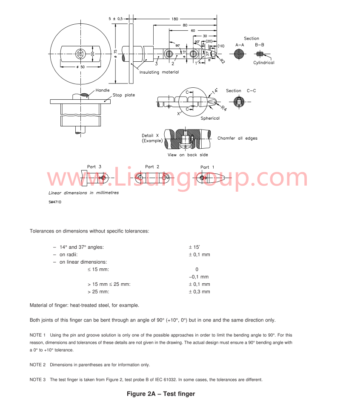

IEC 61032 Figure 2 Articulated Test Probe (Test Probe B) is designed to simulate a human finger, verifying whether hazardous live or mechanical parts in electrical equipment are inaccessible. It features a heat-treated stainless steel “finger” with chrome plating for durability, paired with a non-slip polyamide handle. Its two joints bend 90° (±10° tolerance) in the same plane/direction—mimicking real finger movement— and it applies a precise 10N thrust. Compliant with global standards like IEC, UL, and CSA, it’s essential for safety compliance checks across appliances, IT devices, and medical equipment.

Specifications:

• Probe Type: IEC 61032 Standard Articulated Test Probe (Test Probe B, finger simulation)

• Finger Material: Heat-treated stainless steel (corrosion-resistant, rigid for consistent testing)

• Handle Material: Polyamide (insulating, non-slip for safe grip)

• Surface Finish: Chrome plating (enhances durability, prevents scratches on equipment)

• Applied Thrust: 10N (precise force for standard compliance)

• Joint Movement: 90° angle (0° to +10° tolerance) in the same plane and direction (both joints)

• Key Dimensions:

– Handle Diameter: 75 mm ± 0.5 mm

– Joint Diameter: 12 mm (chamfered edges)

– Stop Face Diameter: 50 mm

– Finger Length (relevant section): 160 mm (linear tolerance: >25mm ±0.3mm)

• Core Function: Simulates human finger access to verify inaccessibility of hazardous parts in equipment

Test Procedures:

• Inspect the probe for damage (e.g., bent finger, cracked handle, stuck joints).

• Adjust the two joints to a 90° angle (as needed) to mimic natural finger movement.

• Hold the polyamide handle and align the stainless steel finger with equipment openings.

• Apply steady 10N thrust to the finger toward potential hazardous parts.

• Check if the finger touches any live/mechanical hazards.

• Record whether the equipment meets safety requirements (pass/fail).

Applications:

• Safety testing of household appliances (e.g., refrigerators, washing machines) to block finger access to hazards (per IEC 61032 Figure 2).

• Compliance checks for IT equipment (e.g., laptops, routers).

• Verification of medical electrical devices (e.g., home-use blood pressure monitors).

• IP code-related access testing for luminaire enclosures (e.g., ceiling lights).

• UL 60335-1 compliance testing for small kitchen appliances (e.g., blenders, toasters).

IEC 61032 Standard Articulated Test Probe with 10N Thrust

IEC 61032 Standard Articulated Test Probe with 10N Thrust

Tags:IEC 61032 , SMT-02T10