Product No: GNGPL-3632

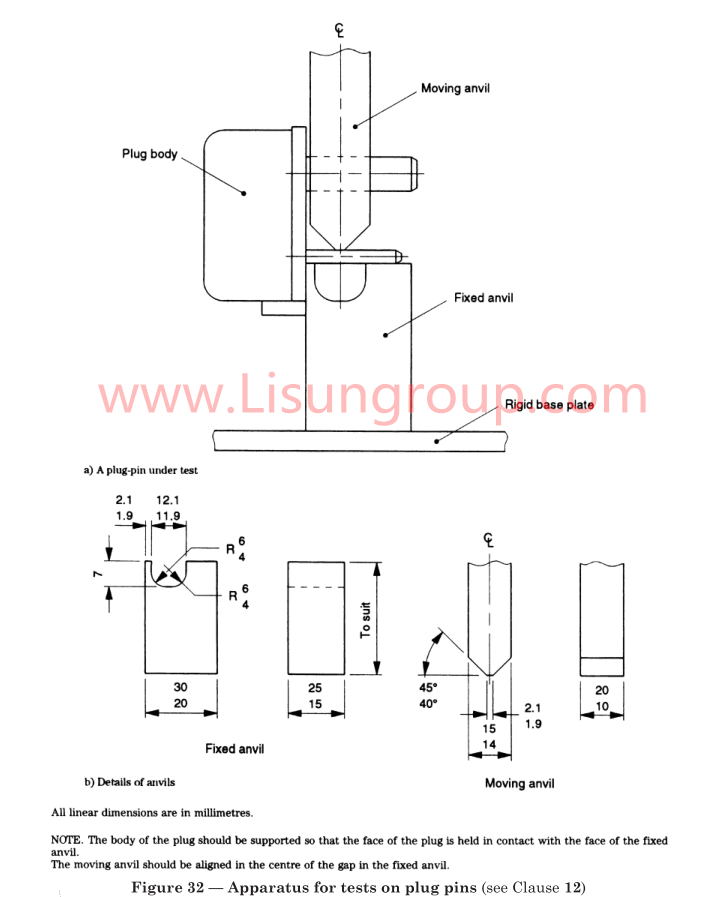

BS 1363-1 Figure 32 Test Apparatus for Tests on Plug Pins is a specialized tool engineered to assess the structural and dimensional compliance of plug pins with BS 1363 standards, as specified in Figure 32 of BS 1363-1 (“13 A plugs, socket-outlets, adaptors and connection units – Rewirable and non-rewirable 13 A fused plugs. Specification”). It features a precision-designed structure with fixed and moving anvils, adhering strictly to the standard’s requirements for dimensions, tolerances, material properties, hardness, and surface roughness. With a material hardness exceeding 50HRC and a low thermal expansion coefficient, the apparatus ensures exceptional dimensional stability and reliability, enabling accurate and consistent testing of plug pins to validate their conformance to critical specifications.

Specifications

• Compliance standard: BS 1363-1 (“13 A plugs, socket-outlets, adaptors and connection units – Rewirable and non-rewirable 13 A fused plugs. Specification”) Figure 32

• Core components: Fixed anvil and moving anvil

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• All linear dimensions: Specified in millimetres

• Key dimensional details: Includes R 4, R 6 radii, 45°, 40° angles, and critical length/width parameters as per standard

• Support requirement: Plug body must be supported to keep its face in contact with the fixed anvil’s face

• Alignment requirement: Moving anvil must be aligned to the centre of the gap in the fixed anvil

• Key attributes (dimensions, tolerances, material, surface roughness): Fully compliant with BS 1363 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

Test Procedures

• Prepare the plug sample for testing, ensuring the plug pins are free from damage, deformation, or debris that could affect test accuracy.

• Inspect the test apparatus to confirm the fixed and moving anvils are clean, free from wear or misalignment, and all specifications meet BS 1363-1 Figure 32 requirements.

• Position the plug sample in the apparatus, supporting the plug body such that the face of the plug is firmly in contact with the face of the fixed anvil (per standard NOTE).

• Align the moving anvil precisely to the centre of the gap in the fixed anvil to ensure accurate measurement.

• Secure the plug sample to prevent movement during the test, maintaining proper contact with the fixed anvil.

• Conduct the test by operating the moving anvil in accordance with Clause 12 of the BS 1363-1 standard, verifying the plug pin’s structural integrity and dimensional conformity.

• Cross-check the plug pin’s key dimensions (e.g., length, width, radii, angles) against the apparatus’s calibrated parameters to ensure adherence to tolerance limits.

• Record the test results comprehensively, indicating whether the plug sample meets the BS 1363 standard based on the apparatus’s inspection findings.

Applications

• Dimensional and structural compliance testing of plug pins against BS 1363-1 Figure 32 requirements.

• Quality control and inspection processes in the electronics industry for 13 A fused plugs (rewirable and non-rewirable).

• Compliance verification in the electrical appliance industry to ensure the safety and compatibility of plug assemblies.

• R&D and production quality assurance for manufacturers of 13 A plugs, socket-outlets, adaptors, and related connection units.

• Conformity assessment for electrical component manufacturers requiring adherence to BS 1363-1 standards.

• Routine inspection of plug pins in industries relying on standardized 13 A plug systems to maintain product quality and safety.

Test Apparatus for Tests on Plug Pins of BS 1363-1 Figure 32