Product No: GNGPL-3623

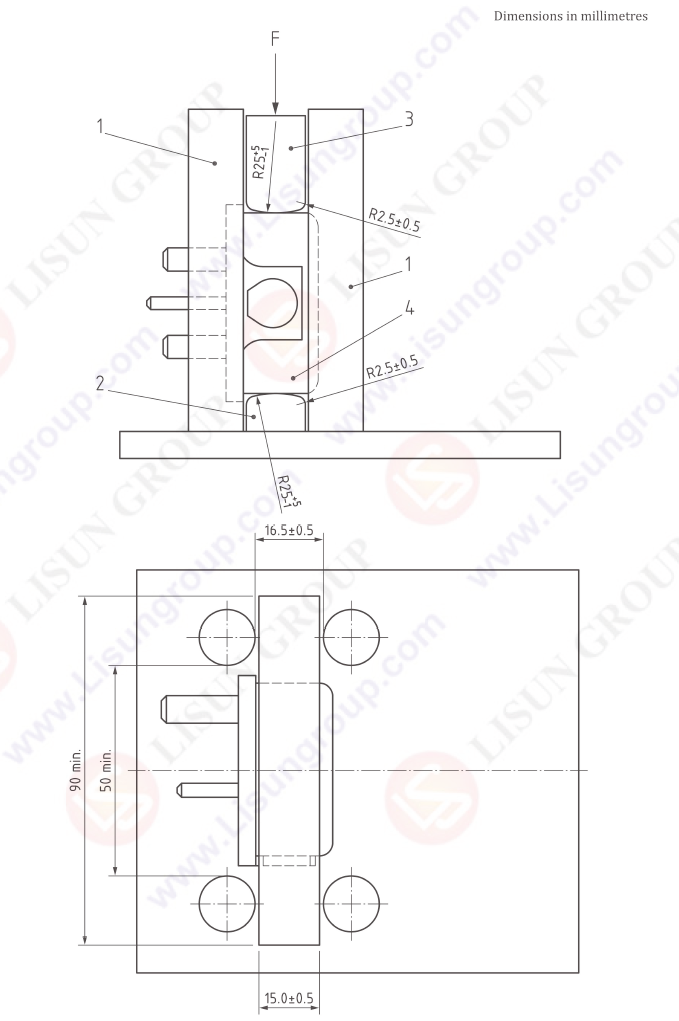

This Apparatus for Pressure Test Designed According to BS1363-2 Figure 23 is a professional testing tool meticulously engineered in strict accordance with BS 1363-2 Figure 23 standards, specifically developed for evaluating the pressure resistance performance of 13 A switched and unswitched socket-outlets. With precision-machined dimensions and structural design optimized for test stability, it delivers consistent and reliable pressure application to simulate real-world stress conditions. The product ensures that socket-outlet components meet the rigorous safety and durability requirements of international electrical standards, making it an indispensable instrument for quality control, certification, and R&D in the electrical accessory industry.

Specifications

• Test standard compliance: BS 1363-2 (relevant to 13 A switched and unswitched socket-outlets) Figure 23

• Key dimensional parameters: 16.5 ± 0.5 mm (major linear dimension), 15.0 ± 0.5 mm (secondary linear dimension)

• Radius specifications: Dual R2.5 ± 0.5 mm rounded features for compatible contact with test samples

• Test pressure duration range: 50 minutes to 90 minutes (adaptable to standard-specified test cycles)

• Structural design: Engineered for stable pressure application, ensuring uniform force distribution on test samples

• Manufacturing precision: All critical dimensions adhere to strict tolerances to meet BS 1363-2 requirements

• Compatibility: Tailored for 13 A socket-outlets (both switched and unswitched types) covered by the standard

Test Procedures

• Prepare the test environment by ensuring the apparatus is placed on a flat, stable surface and calibrated to meet dimensional and pressure accuracy requirements.

• Select the 13 A switched or unswitched socket-outlet to be tested and inspect it for any pre-existing damage or defects that may affect test results.

• Mount the test sample securely in the designated fixture of the pressure test apparatus, ensuring proper alignment with the apparatus’s contact surfaces.

• Verify that the apparatus’s rounded features (R2.5 ± 0.5 mm) are in full contact with the specified test points of the socket-outlet.

• Set the test duration according to BS 1363-2 protocols, selecting either 50 minutes or 90 minutes based on the specific test requirements.

• Initiate the pressure test, ensuring the apparatus applies consistent pressure to the sample throughout the set duration.

• Monitor the test process continuously to prevent any misalignment, pressure fluctuation, or sample displacement.

• Upon completion of the test duration, stop the apparatus and carefully remove the sample without causing additional stress or damage.

• Inspect the tested socket-outlet for signs of deformation, cracking, or functional failure, and document all observations in line with standard evaluation criteria.

• Compare the test results against BS 1363-2 requirements to determine the sample’s compliance with pressure resistance standards.

Applications

• Pressure resistance testing of 13 A switched socket-outlets to validate compliance with BS 1363-2 standards.

• Performance evaluation of 13 A unswitched socket-outlets for durability under specified pressure conditions.

• Quality control inspections in manufacturing facilities producing socket-outlets for markets adhering to BS 1363-2 specifications.

• Certification testing conducted by third-party laboratories and regulatory bodies to confirm product conformity.

• R&D testing for optimizing the structural design and material selection of 13 A socket-outlets to enhance pressure resistance.

• Pre-shipment quality verification for exporters ensuring products meet the pressure safety requirements of target markets.

• Routine quality audits for electrical accessory brands to maintain consistent product performance and safety standards.

Apparatus for Pressure Test Designed According to BS1363-2 Figure 23