Product No: GNGPL-3608

This Plug Pins of BS1363-1 Figure 8 is precision-engineered in strict compliance with the specifications outlined in BS 1363-1 Figure 8, which applies to rewirable and non-rewirable 13 A fused plugs. It is specifically designed to verify the dimensional accuracy, pin disposition, and deflection performance of plug pins, ensuring that 13 A plugs meet the rigorous safety and technical standards for electrical connection units, thus supporting reliable quality control in production and testing processes.

Specifications:

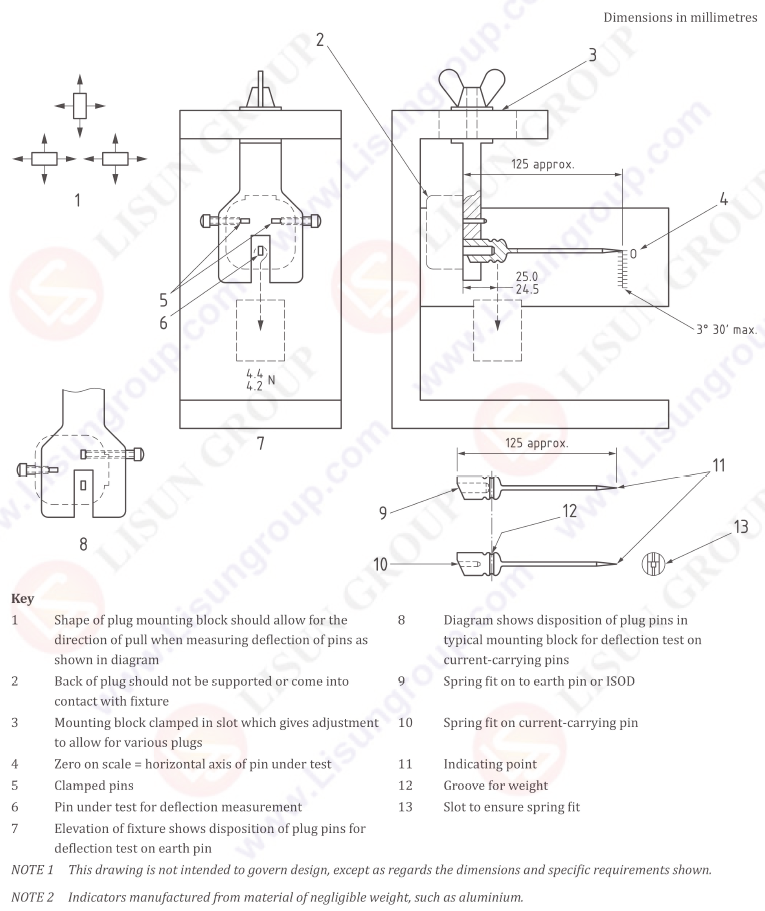

• Fully conforms to BS 1363-1 standard requirements, aligning with Figure 8 specifications for 13 A fused plugs

• Features precise dimensional calibrations in millimetres (including key dimensions relevant to pin structure and disposition)

• Supports deflection testing for both current-carrying pins and earth pins

• Incorporates a specialized mounting block design that allows for the correct direction of pull during deflection measurement

• Equipped with spring fits for earth pins (or ISOD) and current-carrying pins to ensure secure positioning

• Includes a groove for weight attachment and a slot to guarantee spring fit, as specified in the standard

• Maximum allowable angular tolerance for pins: 3° 30′ max

• Indicating points manufactured from low-weight materials (e.g., aluminium) to avoid interference with test results

• Zero on the measurement scale aligns with the horizontal axis of the pin under test

Test Procedures:

• Ensure the test tool is properly calibrated and the mounting block is securely clamped in the adjustable slot to accommodate the specific plug model.

• Prepare the 13 A fused plug sample (rewirable or non-rewirable) and confirm it is free from damage, deformation, or contamination that may affect test results.

• Position the plug in the mounting block according to the specified pin disposition shown in the diagram, ensuring the back of the plug does not contact or receive support from the fixture.

• Secure the plug pins using the designated spring fits (for earth pin/ISOD and current-carrying pins) to maintain proper alignment during testing.

• For deflection testing: Attach the required weight to the groove on the pin under test, following the direction of pull indicated in the diagram.

• Use the indicating point to measure the deflection of the current-carrying pins and earth pin separately, referencing the zero scale aligned with the pin’s horizontal axis.

• Verify that the pin dimensions, disposition, and deflection values comply with the requirements outlined in BS 1363-1 Figure 8.

• Record all test data, including dimensional measurements and deflection results, and document whether the sample meets the standard.

• Note any deviations from the specified requirements and adjust the test process as needed for subsequent samples.

Applications:

• Quality control testing of plug pins for rewirable and non-rewirable 13 A fused plugs in manufacturing facilities.

• Dimensional accuracy and deflection performance verification during the R&D phase of plug design.

• Compliance assessment by certification bodies and third-party testing laboratories for 13 A electrical connection units.

• Routine inspection of plug production lines to ensure consistent adherence to BS 1363-1 standards.

• Performance validation of plug pins for electrical equipment manufacturers relying on 13 A plug compatibility and safety.

• Quality assurance for suppliers of plug components to ensure conformance with industry-specific technical requirements.

Plug pin of BS1363-1 Figure 8