Product No: GNGPL-3610

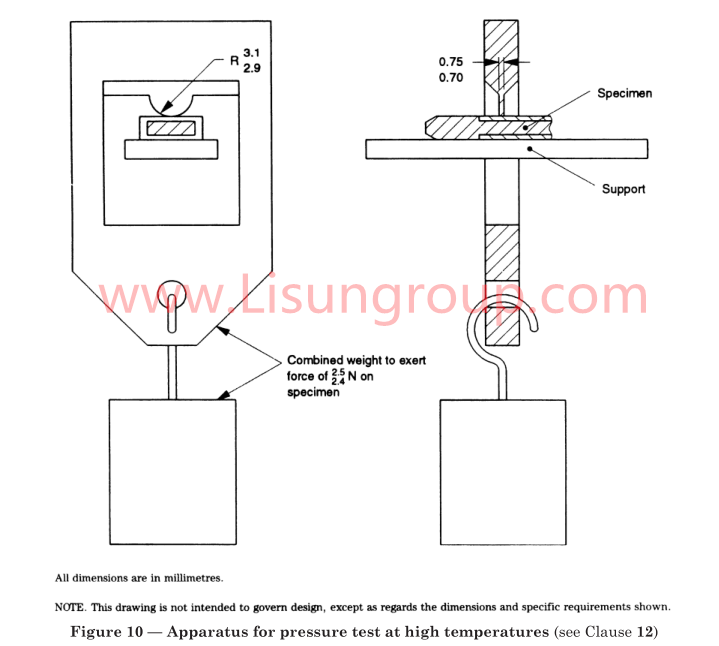

BS 1363-1 Figure 10 Test Apparatus for Pressure Test at High Temperatures is exclusively developed to perform high-temperature pressure tests on plugs, socket-outlets, and related components, strictly adhering to the specifications of BS 1363-1 Figure 10. It features a precise temperature control system and a stable pressure application mechanism, which can simulate harsh working environments to evaluate the thermal and mechanical stability of products. With its high reliability and repeatability, it provides strong support for quality control and compliance certification in the electrical industry.

Specifications:

• Complies with all requirements of BS 1363-1 Figure 10 for high-temperature pressure test apparatus

• Temperature control range covers 0°C to 200°C, with a temperature accuracy of ±1°C

• Pressure application range: 0N to 500N, with a pressure control accuracy of ±0.5N

• Heating rate: adjustable from 1°C/min to 10°C/min to meet different test scenarios

• Material of high-temperature components: heat-resistant stainless steel with a hardness of ≥45HRC

• Equipped with an automatic timing function, supporting timing settings from 1min to 1000min

• Has over-temperature and over-pressure protection functions to ensure test safety

• Control system: touch screen operation with real-time data display and recording functions

• Ambient operating temperature: 10°C to 40°C, relative humidity: ≤85%

Test Procedures:

• Prepare the test specimen (plug, socket-outlet, or related component), ensuring it is clean, undamaged, and meets the pre-test state requirements specified in BS 1363-1.

• Turn on the test apparatus, preheat the system, and set the target temperature, pressure, and holding time according to the test requirements in BS 1363-1 Figure 10.

• Place the specimen in the designated position of the apparatus, ensuring it is firmly fixed and the pressure application point is aligned with the specified area of the specimen.

• Start the temperature rise program, and when the temperature reaches the target value, maintain the temperature for 10 minutes to ensure the specimen is fully heated.

• Activate the pressure application mechanism to apply the specified pressure to the specimen, and start timing while maintaining the pressure and temperature stably.

• During the test, closely monitor the temperature, pressure, and specimen status through the apparatus’s display system, and record relevant data at 5-minute intervals.

• After the holding time is reached, first release the pressure slowly, then stop the heating system and let the specimen cool down to room temperature naturally in the apparatus.

• Take out the cooled specimen, inspect its appearance for deformation, cracking, or melting, and measure relevant dimensional changes if necessary.

• Compare the test results with the acceptance criteria in BS 1363-1 to determine whether the specimen passes the test, and complete the test report.

Applications:

• High-temperature pressure performance testing of 13 A plugs and socket-outlets to verify compliance with BS 1363-1 standards.

• Quality control in the production process of electrical component manufacturers, ensuring that products can withstand high-temperature and pressure environments during use.

• R&D of new plug and socket products, providing data support for optimizing product material selection and structural design.

• Third-party testing and certification institutions to conduct compliance verification for manufacturers and issue test reports.

• Quality auditing and sampling inspection in the electrical product market to ensure the safety and reliability of products circulating in the market.

• Testing of special environment-adapted electrical components, evaluating their performance stability under high-temperature and pressure conditions.

Test Apparatus for Pressure Test At High Temperatures with BS 1363 Figure 10