Product No: SMT-1203

The CEI 23-50 Fig.5 Test Probe is a specialized tool for inspecting notches, holes, and reverse tapers in electrical lighting equipment—critical for ensuring compliance with Italian safety norms. Designed without a cable (with a cabled version available for low-voltage testing), it features a rigid, precision-machined metal body with a right-angled sharp edge, ensuring accurate detection of non-compliant openings. Its durable construction withstands repeated use, making it ideal for manufacturers, labs, and certifiers verifying lighting equipment safety for the Italian market.

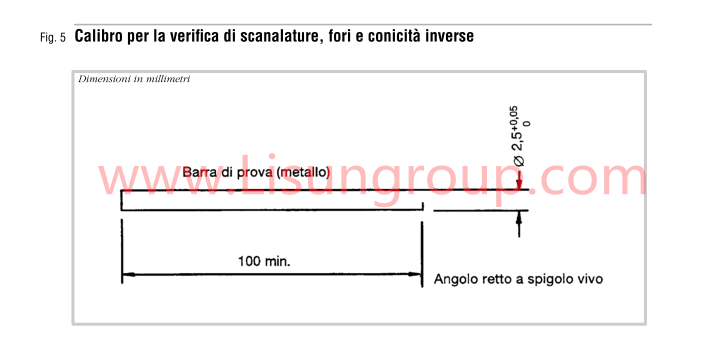

Specifications:

• Overall Length: Minimum 100mm (meets CEI 23-50 Fig.5 dimensional requirements)

• Edge Design: Right-angled sharp edge (for precise detection of notches/reverse tapers)

• Cable Configuration: Base model (no cable); Cabled version available for low-voltage test supply compatibility

• Material: High-strength stainless steel (corrosion-resistant, maintains shape and edge sharpness)

• Tolerances: Linear dimensions: ±0.2mm (ensures alignment with CEI 23-50 Fig.5 specs)

• Functional Compatibility: Works independently; Cabled variant pairs with low-voltage test supplies (e.g., LISUN SMT-529CV)

Test Procedures:

• Inspect the probe for bent metal, dulled edges, or damage; confirm length and edge sharpness meet specs.

• Power off the lighting equipment under test and place it on a stable, flat surface.

• Identify target areas: notches, holes, or reverse-tapered openings on the fixture.

• Hold the probe by its non-slip grip (if equipped) and align the sharp edge with the target opening.

• Gently insert the probe to check if the opening’s size/shape complies (no excessive gap or non-compliant taper).

• Record results to verify adherence to CEI 23-50 Fig.5 requirements.

Applications:

• Safety testing of residential lighting fixtures (e.g., ceiling fans with lights, wall sconces) to check notch/hole compliance for Italy.

• Compliance checks for commercial lighting (e.g., office downlights, retail track lights) per CEI 23-50.

• Quality control for LED lighting manufacturers producing fixtures with openings (ensuring no non-compliant tapers/notches).

• Third-party certification testing (e.g., IMQ, CE) for lighting products entering the Italian market.

• Pre-shipment verification of outdoor lighting (e.g., patio lights, streetlight housings) to meet Italian safety standards.

Calibro per la verifica di scanalature, fori e conicit¨¤ inverse OF CEI 23-50 Fig. 5