Product No: GNGPL-3633

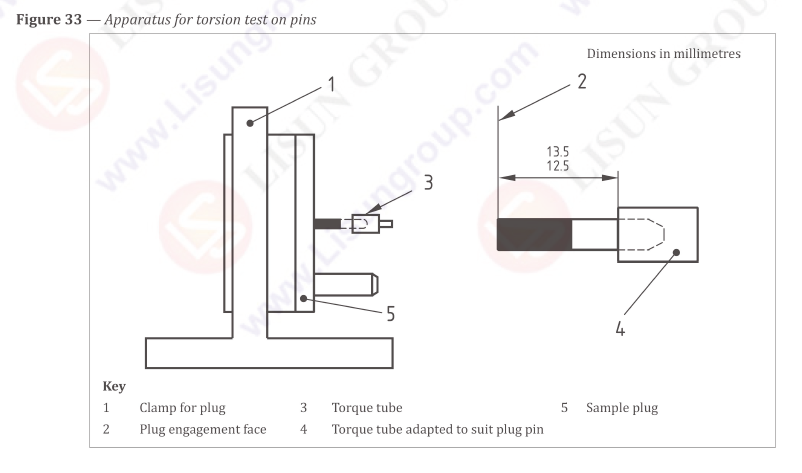

This BS1363-1 Figure 33 Apparatus for Torsion Test on Pins is a specialized testing tool meticulously engineered in full compliance with BS 1363-1 Figure 33, designed exclusively to evaluate the torsional strength and structural integrity of pins in 13 A rewirable and non-rewirable fused plugs. It features a precision-machined structure including a plug clamp, dedicated plug engagement face, and a torque tube adapted to match plug pin specifications, ensuring accurate and consistent torque application during testing. The apparatus delivers reliable test conditions that simulate real-world stress on plug pins, making it an essential instrument for verifying product compliance with international electrical safety standards, supporting quality control and certification processes in the electrical accessory industry.

Specifications

• Test standard compliance: BS 1363-1 Figure 33 (dedicated for torsion testing of 13 A fused plug pins)

• Core components: Plug clamp, plug engagement face, torque tube (adapted to suit plug pins), sample plug mounting structure

• Key dimensional parameter: 13.5 mm (critical dimension as specified in the standard)

• Structural design: Torque tube tailored to fit plug pin geometry for precise torque transmission; secure plug clamp to prevent sample displacement during testing

• Compatibility: Optimized for 13 A rewirable and non-rewirable fused plugs covered by BS 1363-1

• Functionality: Enables controlled application of torsion force to assess pin resistance against twisting deformation or failure

• Manufacturing precision: Critical components machined to strict tolerances to align with BS 1363-1 requirements

Test Procedures

• Prepare the test environment by placing the apparatus on a stable, flat surface and ensuring all components are securely assembled.

• Inspect the torsion test apparatus for structural integrity, verifying that the plug clamp, torque tube, and engagement face are free of damage or wear.

• Select the 13 A rewirable or non-rewirable fused plug to be tested and inspect its pins for pre-existing defects, deformation, or damage.

• Mount the sample plug into the apparatus’s plug clamp, ensuring the plug engagement face makes full contact with the plug’s designated surface for stable positioning.

• Attach the torque tube to the plug pin, confirming it is properly adapted and securely fitted to avoid slippage during torque application.

• Calibrate the apparatus to ensure torque measurement accuracy, aligning with the requirements specified in BS 1363-1.

• Initiate the torsion test by applying a controlled, gradual torque to the torque tube in accordance with BS 1363-1 protocols.

• Continuously monitor the test process, recording the applied torque and observing the plug pin for signs of deformation, twisting, or failure.

• Stop the test immediately if the pin shows excessive deformation or structural failure, or upon reaching the torque threshold specified by the standard.

• Safely remove the sample plug from the apparatus, document all test data (including applied torque and pin performance), and compare results against BS 1363-1 requirements to assess compliance.

Applications

• Torsional strength testing of pins in 13 A rewirable fused plugs to validate compliance with BS 1363-1 standards.

• Structural integrity evaluation of pins in 13 A non-rewirable fused plugs under torsional stress.

• Quality control inspections in manufacturing facilities producing 13 A fused plugs for markets adhering to BS 1363-1 specifications.

• Certification testing conducted by third-party laboratories and regulatory bodies to confirm product conformity.

• R&D testing for optimizing the design, material selection, and manufacturing processes of plug pins to enhance torsional resistance.

• Pre-shipment quality verification for exporters, ensuring plug pins meet the torsional strength requirements of target markets.

• Routine quality audits for electrical accessory brands to maintain consistent product performance and safety standards.

• Failure analysis testing to identify potential weaknesses in plug pin design or production, supporting product improvement initiatives.

Apparatus of BS1363-1 Figure 33