Product No: JL-X

The JL-X series Waterproof Testing Equipment (open type) comprehensively tests the waterproof performance of electronic and electrical product casings. By simulating water ingress conditions under different environments, it verifies the product’s protective capabilities under conditions such as rain, spray and immersion. The JL-X waterproof testing system includes the following levels: IPX1 (Vertically Dripping), IPX2 (15° tilted Dripping), IPX3 (Spraying water), IPX4 (Splashing water), IPX5 (Jetting Water), IPX6 (Powerful Jetting Water), IPX7 (Temporary Immersion in water) and IPX8 (Continuous Immersion in Water).

The IP Waterproof Test Machine can achieve a full range of tests from low-level dripping to high-level deep water immersion, ensuring that the product casing can effectively prevent water intrusion, protect the internal circuits and components, and provide testing support for the reliable operation of products in various humid or water-related environments. During the test, it can simulate key conditions such as rain intensity, spray angle, and immersion depth in the natural environment according to the actual use requirements of the product, accurately assessing the protective effectiveness of the product casing, helping companies to identify protective design defects in advance, and ensuring that products meet relevant market access requirements.

Standards:

| Standards No. | Standards Name |

| IEC 60529:2013 | Degrees of protection provided by enclosure (IP code) |

| IEC 60598-1:2024 | Luminaires – Part 1: General requirements and tests |

| IEC 60034-5:2020 | Rotating electrical machines – Part 5: Degrees of protection provided by the integral design of rotating electrical machines (IP code) – Classification |

| VDE 0470-1 | Testing of enclosures for electrical equipment (IP code) |

| GB/T 4208-2017 | 外壳防护等级(IP 代码) |

| GB/T 7000.1-2023 | 灯具 第 1 部分:一般要求与试验 |

Specifications:

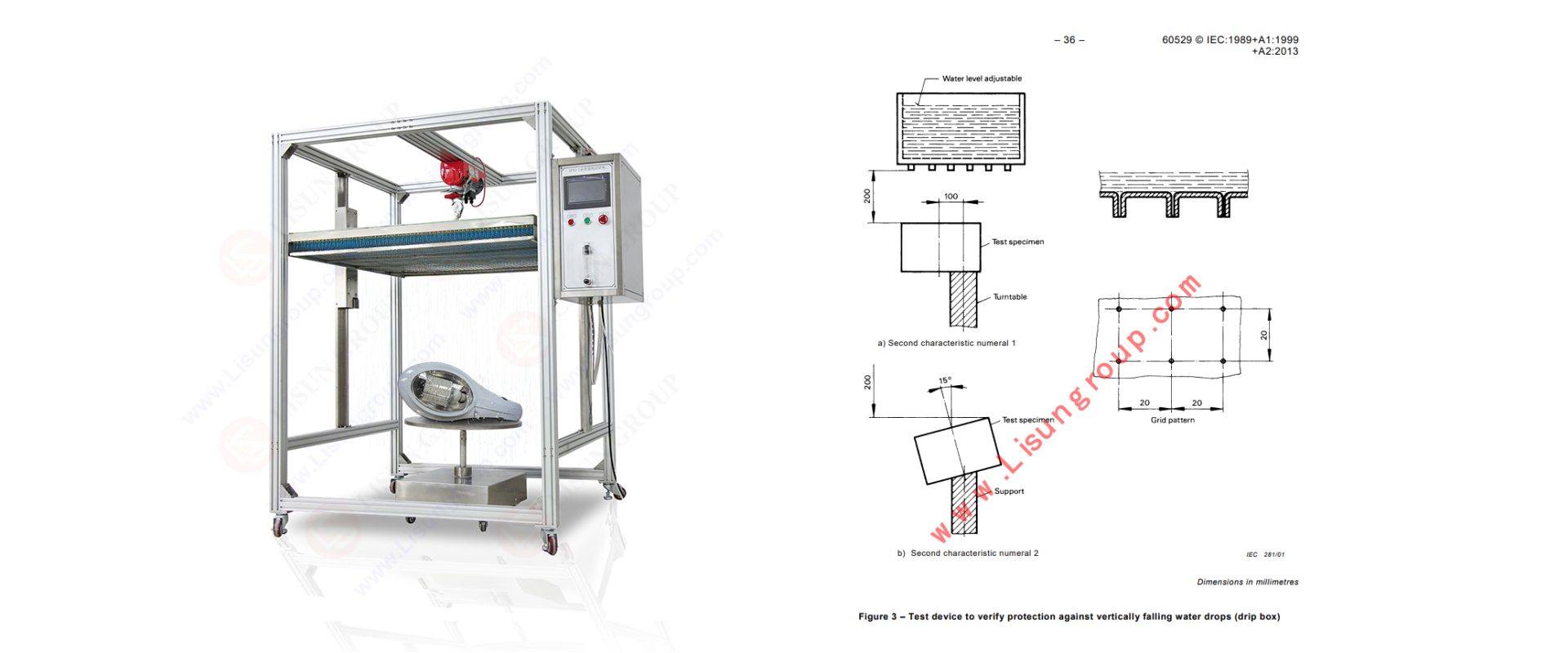

• Drip Box (LISUN model: JL-12): The drip box meets the test requirements of IPX1 and IPX2 in Clause 14.2.1~14.2.2 and Figure 3 of IEC 60529:2013. The drip box size is 800*800*45mm (L*W*H). The diameter of drip hole is 0.4mm. The distance between drip holes is 20mm. It achieves uniform water droplet distribution. Includes a test turntable, with a maximum sample load capacity of 50kg. Equipment power supply: 220~240V/single phase/50Hz (60Hz can be customized). Note: The drip plate and test turntable can be customized according to the maximum size and weight of the object being tested.

JL-12 Drip Box, IEC 60529 Figure 3

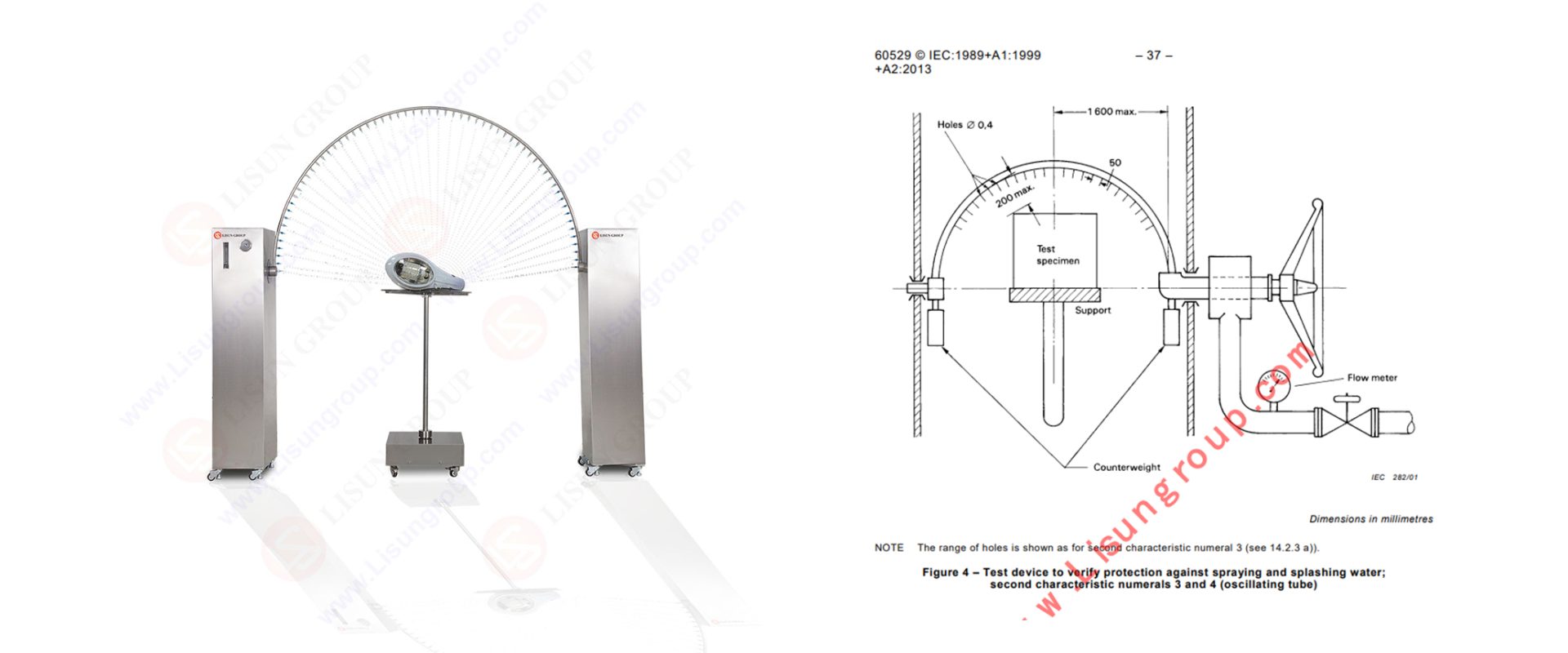

• Oscillating Tube Water Spray Test Equipment (LISUN model: JL-34): Also called Swing Pipe Rain Spray Test Machine, it meets the test requirements of IPX3 and IPX4 in Clause 14.2.3~14.2.4 and Figure 4 of IEC 60529:2013. The standard configuration includes a 1m radius oscillating tube with a 15mm inner diameter; the oscillating angle is 120° for IPX3 level testing and 180° for IPX4 level testing, both angles adjustable as needed; the test turntable rotation speed is 1~5 r/min, the rotation modes include continuous forward rotation, alternating forward and reverse rotation and intermittent rotation, with precise speed regulation achieved by a PLC control board. Equipment power supply: 220~240V/single phase/50Hz (60Hz can be customized).

| LISUN Model | Oscillating Tube、Turntable Diameter/Max Load | IPX3、IPX4 | |||

| Testing Host | Oscillating Tube | Testing Turntable | Numbers of open holes | Total Water Flow | |

| N/A | JL-34-OT-R200 | JL-34-TT-D200KG30 | R=200、D=200mm/30kg | 8、12 | 0.56、0.84 L/min |

| N/A | JL-34-OT-R400 | JL-34-TT-D400KG30 | R=400、D=400mm/30kg | 16、25 | 1.1、1.8 L/min |

| JL-34-R600 | JL-34-OT-R600 | JL-34-TT-D600KG50 | R=600、D=600mm/50kg | 25、37 | 1.8、2.6 L/min |

| JL-34-R800 | JL-34-OT-R800 | JL-34-TT-D800KG50 | R=800、D=800mm/50kg | 33、50 | 2.3、3.5 L/min |

| JL-34-R1000 | JL-34-OT-R1000 | JL-34-TT-D1000KG50 | R=1000、D=1000mm/50kg | 41、62 | 2.9、4.3 L/min |

| JL-34-R1200 | JL-34-OT-R1200 | JL-34-TT-D1200KG50 | R=1200、D=1200mm/50kg | 50、75 | 3.5、5.3 L/min |

| JL-34-R1400 | JL-34-OT-R1400 | JL-34-TT-D1400KG50 | R=1400、D=1400mm/50kg | 58、87 | 4.1、6.1 L/min |

| JL-34-R1600 | JL-34-OT-R1600 | JL-34-TT-D1600KG50 | R=1600、D=1600mm/50kg | 67、100 | 4.7、7 L/min |

Selection Notes:

1. Customers should select the Testing Host, Oscillating Tube and Testing Turntable based on the maximum size of the EUT. The standard selection is LISUN Model JL-34 includes the Testing Host JL-34-R1000, Oscillating Tube JL-34-OT-R1000 and Testing Turntable JL-34-TT-D800KG50.

2. The Testing Host can only be compatible with Oscillating Tubes and Testing Turntables whose specifications do not exceed its corresponding dimensions. For example, when selecting Testing Host JL-34-R1000, the Oscillating Tube can be selected with a radius R = 200~1000mm but not greater than 1000mm, and the Testing Turntable can be selected with a diameter D = 200~1000mm but not greater than 1000mm.

3. For the more heavier EUT weights, the Testing Turntable can be customized according to customer requirements.

4. When selecting the JL-34-R1200 Testing Host and JL-34-OT-R1200 Oscillating Tube, a minimum room height of 2,800mm is recommended; when selecting the JL-34-R1400 Testing Host and JL-34-OT-R1400 Oscillating Tube, a minimum room height of 3,200mm is recommended; when selecting the JL-34-R1600 Testing Host and JL-34-OT-R1600 Oscillating Tube, a minimum room height of 3,600mm is recommended.

JL-34 Swing Pipe Water Spray Test Equipment, IEC 60529 Figure 4

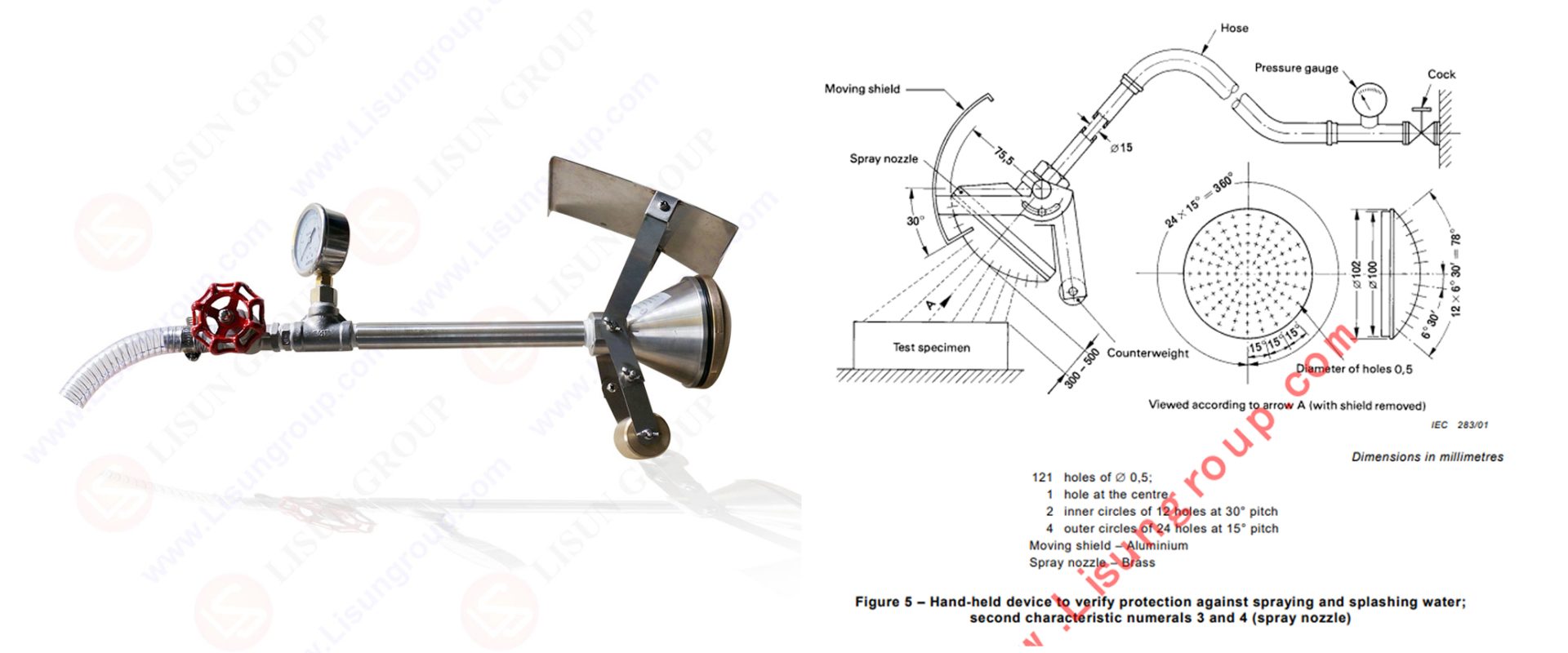

• Spraying Nozzle and Splashing Water Hand held Test Device (LISUN model: JL-34S): It meets the test requirements of IPX3 and IPX4 in Clause 14.2.3~14.2.4 and Figure 5 of IEC 60529:2013. Equipped with a pressure gauge, an 8m long water pipe, and a 0.5mm spray nozzle, the water pressure adjustment range is 50kPa to 150kPa, and the specified flow rate can be achieved by adjusting the water pressure; the test duration is 1 minute per square meter of the calculated surface area of the casing (excluding any mounting surface), and the minimum test time is no less than 5 minutes.

JL-34S Spraying Nozzle and Splashing Water Hand held Test Device, IEC 60529 Figure 5

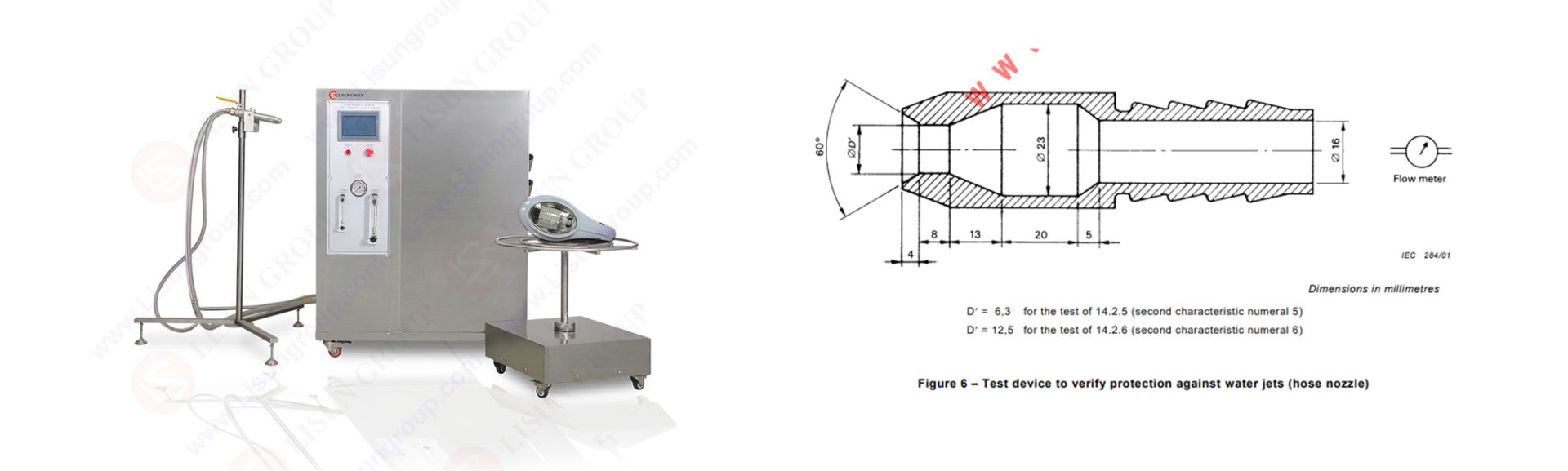

• Waterproof Jet Test Device (LISUN model: JL-56): It meets the test requirements of IPX5 and IPX6 in Clause 14.2.5~14.2.6 and Figure 6 of IEC 60529:2013. The standard water tank dimensions are 780*580*1100mm (L*W*H). For IPX5 level testing, a φ6.3mm nozzle is provided, with the water flow rate controlled at 12.5±0.625L/min; for IPX6 level testing, a φ12.5mm nozzle is provided, with the water flow rate controlled at 100±5L/min. The water pressure can be stably adjusted to meet the testing requirements of different levels. Includes a test turntable, with a maximum sample load capacity of 50kg. Equipment power supply: 380V/Three phases/50Hz (60Hz can be customized).

JL-56 Waterproof Jet Test Device , IEC 60529 Figure 6

• Immersion tank Waterproof test Device (LISUN model: JL-7): It meets the test requirements of IPX7 in Clause 14.2.7 of IEC 60529:2013. The internal dimensions of the test tank are 1000*1000*1200mm (L*W*H), and the maximum load capacity of the test sample is 120kg. The immersion time is fixed at 30 minutes, and the temperature difference between the water and the sample should not exceed 5K. The immersion depth of the sample should be in accordance with the standard: for outer shells with a height less than 850mm, the lowest point must be 1000mm below the water surface; for outer shells with a height equal to or greater than 850mm, the highest point must be 150mm below the water surface. Testing can be performed with the sample powered on or in operation. Note: The internal dimensions and maximum load capacity of the test tank can be customized according to the maximum size and weight of the object being tested.

JL-7 Immersion tank Waterproof test Device

• Immersion tank Waterproof test Device (LISUN model: JL-8): It meets the test requirements of IPX8 in Clause 14.2.8 of IEC 60529:2013. Featuring a cylindrical water tank design with a diameter of 600mm and a height of 1200mm, it can simulate water depths from 0 to 50m and operate at pressures up to 10 atmospheres. Equipment power supply: 220~240V/single phase/50Hz (60Hz can be customized). Note: The diameter and height of the test tank can be customized based on the maximum size and weight of the object being tested.

JL-8 Immersion tank Waterproof test Device

Optional suggestions: When using JL-8 Immersion tank Waterproof test Device , it is necessary to choose a LISUN LS-EU800W2-55L air compressor (power 800W*2, capacity 55L, speed 1380r/min, pressure 0.7Mpa, flow 120L/m in, 220~240V/50Hz) or LS-US800W2-55L air compressor (power 800W*2, capacity 55L, speed 1380r/min, pressure 0.7Mpa, flow 120L/min, 110~120V/60Hz).

LS-EU800W2-55L Air Compressor

Typical Applications:

1. Compliance testing of waterproof protection ratings for LED lighting fixture housings

2. Factory inspection of product housing protection performance by quality control departments of electronic and electrical appliance manufacturers

3. Verification and optimization testing of waterproof design schemes for lighting fixture housings during the R&D process

4. Waterproof performance compliance testing of home appliances (such as outdoor speakers and security cameras) before market launch

5. Confirmation testing of the overall structural protection level of rotating motors during the production of motor equipment

6. Specialized testing by third-party certification bodies for issuing waterproof performance test reports for electronic and electrical products

LISUN JL-12 IP Waterproof Test Equipments – After-sales Frequently Asked Questions (FAQ)

LISUN JL-12 IP Waterproof Test Equipments were in the market for more than 10 years, LISUN engineers service team already summary the most of the After Sales Questions and Answers in the above link. Please read it carefuly, you can solve the most of the problems by yourself if you have some questions while using the instruments. LISUN will be continue to update this pages and more FAQ can be found in this topic link.

LISUN JL-34 IP Waterproof Test Equipments – After-sales Frequently Asked Questions (FAQ)

LISUN JL-34 IP Waterproof Test Equipments were in the market for more than 10 years, LISUN engineers service team already summary the most of the After Sales Questions and Answers in the above link. Please read it carefuly, you can solve the most of the problems by yourself if you have some questions while using the instruments. LISUN will be continue to update this pages and more FAQ can be found in this topic link.

LISUN JL-56 IP Waterproof Test Equipments – After-sales Frequently Asked Questions (FAQ)

LISUN JL-56 IP Waterproof Test Equipments were in the market for more than 10 years, LISUN engineers service team already summary the most of the After Sales Questions and Answers in the above link. Please read it carefuly, you can solve the most of the problems by yourself if you have some questions while using the instruments. LISUN will be continue to update this pages and more FAQ can be found in this topic link.

LISUN JL-8 IP Waterproof Test Equipments – After-sales Frequently Asked Questions (FAQ)

LISUN JL-8 IP Waterproof Test Equipments were in the market for more than 10 years, LISUN engineers service team already summary the most of the After Sales Questions and Answers in the above link. Please read it carefuly, you can solve the most of the problems by yourself if you have some questions while using the instruments. LISUN will be continue to update this pages and more FAQ can be found in this topic link.

Our company just ordered some instruments from them, due to COVID-19 and their engineer can't visit us to install, thanks to Lisun's perfect videos and we can easy to install, calibrate and testing by ourselves successfully.