Product No: GDJS-015B

The GDJS Series High-Low Temperature & Humidity Cycling Test Chamber (Constant Temperature & Humidity Chamber), GDJW Series High-Low Temperature Aging Chamber, and GW Series Oven Chamber are equipment independently developed by LISUN for verifying the environmental adaptability and reliability of materials and products. By accurately simulating multiple climatic scenarios—such as “low-temperature resistance, high-temperature heat resistance, humidity aging, and dry-wet cycling”—these chambers reproduce the dynamic changes of temperature and humidity in natural environments. They accelerate the evaluation of product performance stability and structural reliability under extreme or cyclic climatic conditions, ultimately determining whether the weather resistance of materials and products meets the expected application requirements.

These test chambers focus on core testing needs of industries including LED lighting, electronic appliances, and components. Particularly for the luminous flux maintenance testing of LED lamps (fully complying with the IES LM-80-08 standard), they can provide a long-term stable temperature and humidity control environment. Meanwhile, they feature core advantages of “wide temperature range coverage + high-precision temperature and humidity control”, paired with imported components and multiple safety protection systems to ensure the accuracy, stability, and safety of the testing process.

Whether for long-term aging verification of LED lamps, high-low temperature performance testing of electronic components, or humidity and heat resistance evaluation of materials, these test chambers can provide scientific testing solutions. They serve as key environmental simulation tools for industrial product R&D verification, production quality inspection, and compliance certification.

Standard:

| Standard No | Standard Name |

| IES LM-80-08 | Approved Method: Measuring Lumen Maintenance of LED Light Sources |

| IEC 60068-3-1:2023 RLV | Environmental testing – Part 3-1: Supporting documentation and guidance – Cold and dry heat tests |

| IEC 60068-2-30:2005 | Environmental testing – Part 2-30: Tests – Test Db: Damp heat, cyclic (12 h + 12 h cycle) |

| IEC 60068-2-14:2009 | Environmental testing – Part 2-14: Tests – Test N: Change of temperature |

| IEC 60598-1:2024 | Luminaires – Part 1: General requirements and tests |

| AEC-Q102 REV A:2020 | Stress Test Qualification for Discrete Optoelectronic Semiconductors |

| ISO 16750-4:2018 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 4: Climatic loads |

| GB/T 2423.1-2008 | 电工电子产品环境试验 第 2 部分:试验方法 试验 A:低温 |

| GB/T 2423.2-2008 | 电工电子产品环境试验 第 2 部分:试验方法 试验 B:高温 |

| GB/T 2423.4-2008 | 电工电子产品环境试验 第 2 部分:试验方法 试验 Db:交变湿热(12h+12h 循环) |

| GB/T 10586-2025 | 湿热试验箱技术规范 |

| GB/T 5170.2-2020 | 环境试验设备检验方法 第 2 部分:温度试验设备 |

| GB 7000.1-2023 | 灯具 第 1 部分:一般要求与试验 |

| GB/T 28046.4-2011 | 道路车辆 电气及电子设备的环境条件和试验 第 4 部分:气候负荷 |

Specification:

• Inner Tank & Insulation: The inner tank is made of SUS304 stainless steel, featuring corrosion resistance and easy cleaning, suitable for long-term humidity-heat testing. The insulation layer consists of “rigid polyurethane foam + ultra-fine glass fiber”; the door frame is equipped with high-temperature aging silicone rubber sealing strips to prevent temperature and humidity leakage.

• Control System: Adopts a self-developed dual-core control of temperature controller + PLC, supporting English operation. It is equipped with USB/RS-232/RS-485 interfaces, enabling connection to a computer for remote monitoring and data traceability.

• Humidity Sensing & Water Supply: Equipped with a Vaisala (Finland) humidity sensor, which has higher accuracy than traditional wet-dry bulb sensors and requires no regular maintenance, reducing operation and maintenance costs. It is also paired with an automatic purified water supply system.

• Temperature Sensor: Uses a platinum resistance PT100Ω/MV temperature sensor, ensuring high precision and strong anti-interference capability.

• Heating System: Adopts an independent nickel-chromium alloy electric heater, which offers high heating efficiency, uniform heat generation, no local overheating, and achieves precise temperature control when combined with the temperature control system.

• Refrigeration System: Features a fully enclosed air-cooled single-stage compression system, equipped with an original TECUMSEH (France) compressor, enabling convenient global after-sales service.

• Circulation System: Includes a temperature-resistant, low-noise air-conditioning type motor (≤65dB) and a multi-blade centrifugal wind wheel, ensuring uniform distribution of temperature and humidity inside the chamber.

• Safety Protection: Integrates multiple protections, including leakage protection, short-circuit protection, heating tube overheating protection, motor overheating protection, and compressor overpressure/overload/overcurrent protection, safeguarding equipment and test safety.

• Power & Operating Environment: Operating voltage is AC 380V±10% three-phase, supporting 50Hz/60Hz. The equipment shall operate in an environment with temperature 5℃~30℃ and humidity ≤85% RH (no condensation, well-ventilated).

| High & Low Temperature Humidity Chamber with Programmable Function (GDJS Series) | ||||||

| LISUN Model | GDJS-100* | GDJS-225* | GDJS-500* | GDJS-010* | GDJS-015* | GDJS-020* |

| Workroom Dimensions | 41*55*45 | 50*60*75 | 70*80*90 | 100*100*100 | 100*100*150 | 100*100*200 |

| External Dimensions | 105*105*156 | 105*102*200 | 132*132*217 | 167*152*231 | 245*160*231 | 160*254*214 |

| Working Power | 5.5kW | 7.0kW | 13.5kW | 15.0kW | 16.5kW | 26.5kW |

| Temperature Range | A: -20℃~150℃ B: -40℃~150℃ C: -60℃~150℃ D: -70℃~150℃ | |||||

| Fluctuation/Evenness | ±0.5℃/±2℃ | |||||

| Temperature Rise Speed | 1.0℃~3.0℃/min | |||||

| Temperature Fall Speed | 0.7℃~1.0℃/min | |||||

| Humidity Range | 20%~98% R.H | |||||

| Humidity Deviation | -2%~-3% R.H | |||||

| High and Low Temperature Chamber with Programmable Function (GDJW Series) | ||||||

| LISUN Model | GDJW-100* | GDJW-225* | GDJW-500* | GDJW-010* | GDJW-015* | GDJW-020* |

| Workroom Dimensions (cm) | 41*55*45 | 50*60*75 | 70*80*90 | 100*100*100 | 100*100*150 | 100*100*200 |

| Temperature Range | A: -20℃~150℃ B: -40℃~150℃ C: -60℃~150℃ D: -70℃~150℃ | |||||

| Fluctuation/Evenness | ±0.5℃/±2℃ | |||||

| Temperature Rise Speed | 1.0℃~3.0℃/min | |||||

| Temperature Fall Speed | 0.7℃~1.0℃/min | |||||

| High Temperature Chamber/Oven Chamber/Aging Oven Testing (GW Series) | |||||

| LISUN Model | GW-225 | GW-500 | GW-010 | GW-015 | GW-020 |

| Workroom Dimensions (cm) | 50*60*75 | 70*80*90 | 100*100*100 | 100*100*150 | 100*100*200 |

| Temperature Range | Enviromental Temperature ~250℃ (Option to 300℃) | ||||

| Fluctuation/Evenness | ±0.5℃/±2℃ | ||||

| Temperature Rise Speed | 1.0℃~3.0℃/min | ||||

The * in GDJS-225*/GDJW-225* means the temperature range A: -20℃-150℃, B: -40℃-150℃, C: -60℃-150℃,D: -70℃-150℃

Temperature Humidity Chamber Test Curve

Temperature Humidity Chamber Programmable Setting

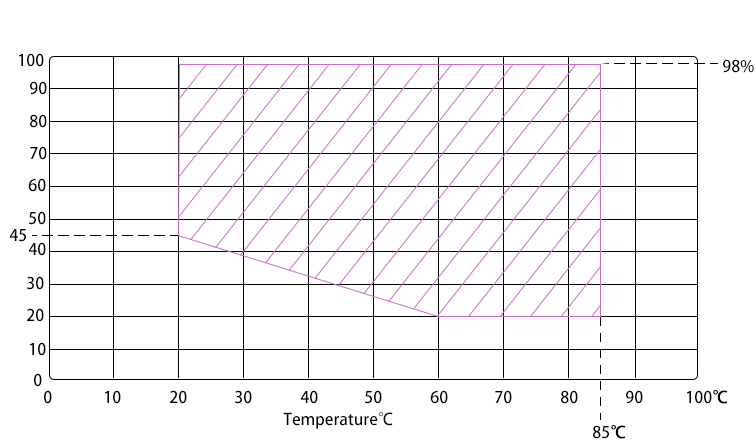

Appendix: GDJS Series Temperature and Humidity Corresponding Chart (Note: This is a regular model. If you have special requirements, please contact us for customization):

GDJS Series Temperature And Humidity Corresponding Chart