EMC (electromagnetic compatibility) includes two parts: EM (electromagnetic sensitivity) and EMI (electromagnetic interference). Usually we call solving the EMC problem. In fact, it is to solve the external radiation interference of electronic equipment, or how to prevent equipment and electronic components from being interfered by electromagnetic wave interference from the outside world. To learn EMC, we must pay attention to basic knowledge, such as electromagnetic waves, electromagnetic fields, and other entry theories. There is an urgent desire to learn. In practice, communicate with others. The effect of learning and communication is much better than one person’s learning problem.

external radiation interference of electronic equipment

Here are the common compatibility problems and specific solutions of EMC engineers for everyone to take learning notes.

1. Why does the ground and power lines of digital circuits often have a large noise voltage? How to reduce these noise voltage?

Digital circuit will instantly absorb a large current when working. When these transient current flows through the power cord and ground wire, due to the existence of the power cord and ground wire inductance, a large rebound voltage will be generated. This is the noise observed noise observed. Voltage. The method of reducing these noise voltage is to reduce the inductance of the power line and ground wire, such as using grid ground, ground surface, power line surface, etc. Another method is to use appropriate decoupled capacitors on the power line (storage Can capacitance).

2. In practice, it is common to twisted multiple wires as high -frequency conductors. It is said that this can reduce the radio frequency impedance of the wire. Why?

This increases the surface area of the wire, thereby reducing high -frequency resistance.

3. Pay special attention to the processing of key signals when designing the electromagnetic compatibility of the circuit or circuit board. The key signals here refer to those signals?

From the perspective of electromagnetic launch, key signal cable refers to cyclical signals, such as this vibration signal, clock signal, low address signal, etc.; From the perspective of sensitivity, key signals refer to signals that are very sensitive to external electromagnetic interference, such as low -electricity, such as low -power Flat -mode signal.

electromagnetic compatibility of the circuit

4. How to prevent the phenomenon of electrochemical corrosion?

Select the metal close to the electrochemical potential, or the environmental sealing of the contact part is separated by an electrolyte.

5. What is overlap and hold several ways to match.

Low impedance (radio frequency) connections between metal components are called overlap. The matching method is welded, riveted, screw connection, and electromagnetic sealing pads.

6. Please list as much as possible to reduce the method of reducing ground -line radio frequency impedance.

Try to use a large surface area to reduce the resistance of high -frequency current; try to make the conductor shorter as possible to reduce the resistance and inductance; place silver on the surface of the conductor to reduce surface resistance;

7. Why do you see some ground wires in some imported prototypes?

In order to make the ground system show different ground structures for signals of different frequencies.

8. What are the root causes of ground interference problems?

The impedance of the ground line is the fundamental cause of the ground line problem. Due to the existence of ground wire impedance, when the current flows on the local line, the voltage will be generated to form a difference in potential. The potential is the same. The ground wire potential is the reference potential of the entire system. The actual ground potential and the assumption conditions have led to a variety of ground wire problems.

9. When analyzing the problem of electromagnetic interference, what definition is often used to describe the ground line?

Define the ground wire as a petition of the signal.

10. When the wires passing through the panel a lot, often use the filter connector or filter array board, and what are the problems when installing the filter connector or filter array board?

To install an electromagnetic sealing cushion between the filter connector or the filter array board or the chassis panel, or use the conductive tape to stick the gap to prevent the electromagnetic leak at the gap.

EMC test venue requirements:

EMC Lab: The EMC test environment. Because the EMC test is a high -precision professional test, the external environment cannot have electromagnetic interference, and the EMC laboratory can block external electromagnetic interference, which is the primary guarantee for EMC testing.

EMC test device: The implementation of the EMC test item, the testing equipment is the core condition of the evaluation. However, the selection of the test equipment also needs to be based on the situation of each company, and comprehensive consideration can be selected to choose the most suitable solution.

What are the EMC laboratory?

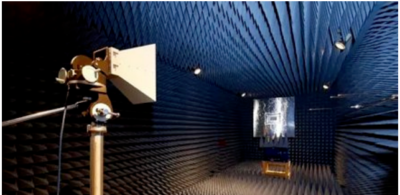

The main venues in EMC testing are in the shielding room, open area, electromagnetic dark chamber, reverberation room, TEM, GTEM. Among them Its environment is “clean”. The principle is to absorb electromagnetic waves with iron oxygen -absorbing materials to achieve electromagnetic interference in the environment. Just like the following figure, the whole steel is closed structure and the internal absorbing material is installed.

GTEM shielding room

RF shielding room

In the radio waves, a composite sponge suction body is filled with cone -shaped wave suction materials, and the angle cone is immersed in suction powder. The size is related to the frequency of absorbing. Eliminating the reflex signal can meet the 30MHz -40GHz frequency band and 10-20dB electromagnetic wave absorption rate; the electromagnetic wave absorption body used in the electromagnetic wave shielding the dark chamber is compatible with the dimensions of the dark chamber, and in order to effectively use the space to continuously reduce the thickness.

GTEM shielding room working principle

RF shielding room working principle

GTEM (Gigaherz Tanseverse Electromagnetic) Cell Test System for Immunity is a new type of electromagnetic compatibility test equipment developed on the basis of the TEM chamber (it application asymmetric rectangular structure to simulate free space to generate TEM electromagnetic waves inside the small chamber), fully meet standard IEC61000-4-3 and GB/T17626.3.

By use of GTEM transverse electromagnetic wave transmission chamber for EMC performance test is a new developed measure technology in the EMC field in recent years. Due to the high wide-band performance of GTEM (from DC to microwave), it can be used for electromagnetic radiation sensitivity EMS (immunity) test, and it can also be used for electromagnetic radiation interference (EMI) test. It necessary test instruments of this system is simple, low cost, easy for fast and automatic control test, it has been highly valued by relevant fields user. Comparing to various test chambers, shielded room, anechoic chamber and open test fields, etc. the GTEM Cell Test System for Immunity is the best cost-effectiveness test solution.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *