EMC compliance testing is used to confirm that an electrical or electronic device does not emit objectionable electromagnetic disturbances or does not excessive become susceptible to causes of electromagnetic disturbances in its natural habitat. The principle of its working is based on coexistence. Various equipment should be able to share the electrical infrastructure and spectrum without interfe...

Instrumentation alone does not give an accurate EMI EMC measurement. It is the sum total of a well-adjusted arrangement with the electromagnetic environment working jointly with the test configuration and operator discipline. Minor differences in grounding cable routing or placing equipment can change the results by several decibels that is usually the difference separating a pass and a failure. E...

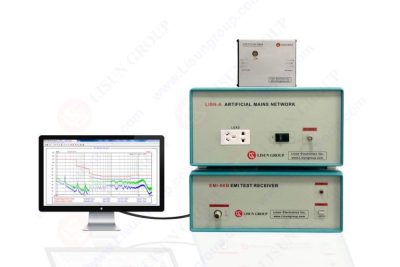

EMI-9KB is popularly utilized in compliance and pre compliance laboratories to obtain fine EMI testing, and a repeatability and stability of testing is of utmost significance. In radiated and conducted measurements of small perturbations across the electromagnetic environment can cause a shift of results by multiple decibels. These variations are not in any way related to the equipment being teste...

EMC conducted emissions testing is one of the starting activities in the contemporary compliance and product development laboratories. It measures unwanted radio frequency energy that travels on line of power and signal instead of traveling through free space. Practically, EMI test of conducted phenomena involves identifying whether a device emits a back injection into the mains or other linked ca...

A good and consistent EMC measurement equipment is crucial in a lab doing compliance test and product development. One component of that ecosystem, which is critical, is the LISN which will serve to fix the line impedance and decouple the equipment under test with supply noise. When the routine maintenance is not taken care of, repeatability of measurements is lost, traceability, and safety are ch...

With the growth of faster, smaller, more interconnected electronic systems, the control of unwanted electromagnetic emissions has become a major task of engineers. It is crucial to know what is EMI and its impact on the efficiency of the system during compliance testing and the development of a product. An EMI spectrum analyzer is vital in this process as it allows an in-depth analysis of interfer...

Proper measurement of undesired emissions is an essential need in the contemporary electronics. In compliance testing, the engineers are required to maintain emission within the limits required by legislations under standardized measuring conditions. An important constituent of this process is the electromagnetic test of interference, wherein the way of detection is indicated and evaluated in rega...

The choice of the appropriate measurement instrument is regarded as one of the most significant choices of any EMC laboratory. EMI test receiver is an integrated instrument in the assessment of undesired electromagnetic pollution that is produced by electronic products. In preliminary design validation up to formal compliance preparation, the quality and consistency of this measure has a direct ra...

The most difficult of the electronics designs to design in terms of electromagnetic compatibility are switching power supplies and SMPS-based circuits. High switching frequencies, short edge transitions and small layouts tend to produce conducted and radiated noise which can readily exceed administrative limits. The EMI-9KB has taken significance in this regard since it enables engineers to detect...

Electromagnetic compatibility has turned out to be a prerequisite in all industries that use electronics. The higher the digital complexity of products, which are increasingly smaller in size, the larger the risk of undesired interference. With communication modules and LED drivers to power supplies and industrial controllers, any device creating electrical switching can potentially cause noise on...

Conducted Emission measurement has a great dependence on electromagnetic compliance testing. Also, in laboratories testing switching power supplies, electronic appliances, industrial controls, medical systems, and automotive modules, the quality of the measurement is not only based on the quality of the receiver, but also based on hardware in the chain of the test. These supporting systems, among ...

The proper use of EMI receiver in advanced laboratories and compliance facilities is important to obtain accurate electromagnetic measurements. Electronic systems are becoming densely connected, high-speed and compact systems, hence increasing the complexity of the undesirable interference. The EMC testing engineers have to depend on precision devices, uniform procedures, and punitive best practic...