Before calculating the ErP energy efficiency rating method, we must first determine whether the lamp under test is a directional light source or a non-directional light source. The judgment method is as follows: First, use the goniophotometer system to test the IES file of the tested luminaire. The directional lamp refers to the luminaire whose effective luminous flux is greater than 80% of the light output of the entire luminaire within the range of the 120° cone solid angle. Non-directional lamp On the contrary, IES will test the luminous flux of the whole lamp and the luminous flux of 120°.

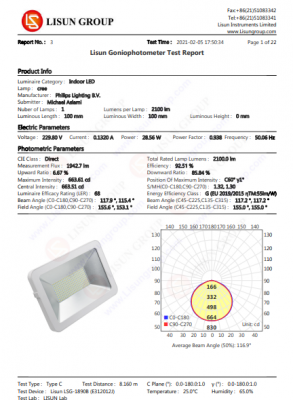

LISUN goniophotometer test report

Through the light distribution curve test, the total luminous flux of this lamp is 1942.7lm, as shown in the figure above.

Goniophotometer test report for beam angle

When the beam angle is set close to 120° by the instrument, the effective luminous flux at this time is 1543.93lm

Then use 120° luminous flux /overall luminous flux,> 80% is a directional light, and <80% is a non-directional light.

The above test is completed by the LSG-1890B high-precision goniophotometer developed by Lisun.

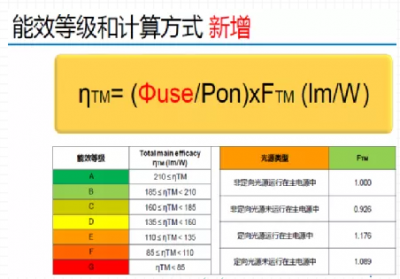

Energy efficiency rating calculation method

Through the IES test report, it can be known that the total luminous flux of the lamp is 1942.7lm, and the effective luminous flux within the 120° beam angle is 1543.93lm.

120° effective luminous flux (1543.93lm)/total luminous flux (1942.7 lm)=0.795, it can be concluded that 79.5% is less than 80%, this is a non-directional light. Its energy efficiency rating ηTM=(1942/23.10)x1.176=98.87 So its energy efficiency rating is F.

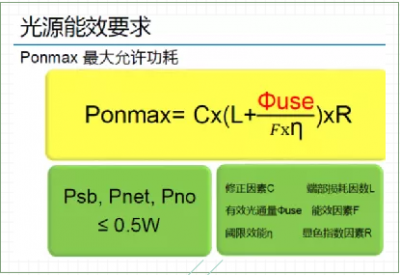

From 1st, September, 2021, the light source should meet the following energy efficiency requirements: It is declared that the full load power cannot exceed the allowable power: Pon ≤ Ponmax, where the Ponmax calculation method is as follows: Ponmax = C *(L +Φuse/(F *η)) * R.

Light source energy efficiency requirements

Light source energy efficiency requirements

According to the above table, there are reports to know

Correction factor C=1.23

End loss factor L=1.5

Effective luminous fluxΦuse=1942

Energy efficiency factor F=0.85

Threshold efficiency η=120

Color rendering index factor (requires integrating sphere test) R=(CRI+80)160

For the color rendering index factor R, you need ues the integrating sphere to get its CRI Ra=91.6, and then apply the above formula

R=(CRI+80)/160

=(91.6+80)/160

=1.07

Then apply the formula Ponmax = C *(L +Φuse/(F *η))* R=21.49.

The LPCE-2 (LMS-9000) High Precision Spectroradiometer Integrating Sphere System developed by LISUN fully meets the color rendering index, color tolerance, luminous flux and other tests.

Light source test report

From the test report of the LPCE-2 High Precision Spectroradiometer Integrating Sphere System, we can get the color temperature of this lamp: 6172k, color rendering index: Ra=72.3, color tolerance: SDCM=2.9, important related information of this lamp, etc.

Through the latest spectrometer analysis software, it is also possible to intuitively measure which energy efficiency class the lamp belongs to, such as testing non-directional lighting products, bulbs and tube products. If you pass the integrating sphere to test the directional lighting products, you must first use the light distribution curve test system to calibrate the integrating sphere luminous flux (test the luminous flux of the luminaire through the luminous distribution curve and calculate the energy efficiency grade method of the luminaire, as described in the first half of the article). The test can measure the energy efficiency level of this directional lighting product (Actually, use the integrating sphere to test the energy efficiency level of the directional lighting product is only save own calculation time, because these formulas have been embedded in the integrating sphere test system In the instrument system software. However, due to the particularity of the luminous flux of the directional lamps, pls. note that you must first use the light distribution curve to test the system, first measure the actual luminous flux of the lamp, and use it to calibrate the integrating sphere.)

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Your email address will not be published. Required fields are marked *