LED chip are small in size, low energy consumption, long life, and other advantages, which promote their rapid development and are widely used in various fields of lighting. Among them, long life is a very important advantage of LED lights. To ensure this advantage of LED, R & D personnel need to ensure good EMC and reliability of the LED power system.

Power system compatibility

The root of improving the reliability of the system lies in the design of the system. To make the components of the system work in a normal state, there is no occurrence of overload and there must be a certain margin. It is also possible to design a backup plan so that the system can still work normally even if a certain component or equipment fails. Of course, the design of the backup scheme may increase the complexity and cost of the system, but if the design is reasonable, it is completely worthwhile to increase the cost and improve the reliability of the system.

Compatibility of LED lighting devices and systems

The compatibility problem of electronic products is mainly electromagnetic compatibility (EMC), which is defined as the coexistence state of equipment, systems, and subsystems that can perform their respective functions together in a common electromagnetic environment. That is to say, the equipment, system, and subsystem will not be detected by electromagnetic emissions from other equipment in the same electromagnetic environment or suffer an unacceptable performance degradation, nor will it cause other equipment, systems, and subsystems in the same electromagnetic environment to be affected by other equipment, systems, and subsystems. Electromagnetic emission causes or suffers an unacceptable performance degradation. Electromagnetic compatibility includes two aspects: electromagnetic interference (EMI) and electromagnetic tolerance (EMS).

The former is mainly manifested as conducted interference and radiation interference. Conducted interference is mainly interference signals generated by sub-station equipment through conductive media or common power lines to interfere with each other; radiated interference refers to interference signals generated by electronic equipment through spatial coupling to transmit interference signals to Electric network or electronic equipment. The latter mainly refers to the ability of the system to withstand interference such as electrostatic discharge, radiation, pulse group, lightning strike, conduction, etc., that is, anti-interference ability. Electronic products are generally classified into civilian, industrial, and military grade products. Products of different grades have different standards and regulations. Products that meet these standards at a specific grade are called electromagnetic compatibility. How to judge whether the product has electromagnetic compatibility? This requires a series of compatibility tests to complete.

Electromagnetic compatibility test

The electromagnetic compatibility test of the system can be divided into two aspects: electromagnetic interference (EMI) and electromagnetic tolerance (EMS). The specific steps used in LED lighting devices and systems are as follows:

Conducted interference

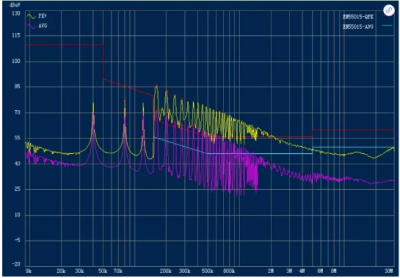

Conducted interference refers to the electromagnetic interference generated by the LED lighting device itself to carry out conductor transportation. This kind of test frequency range is generally 9KHz~30MHz, which is a low frequency phenomenon.

Conducted interference frequency

Radiation interference

Radiation interference is also generated by the device itself, and is an interference electromagnetic wave formed by propagation through space. LED illuminators form external radiation interference from internal circuits through the product’s wire and cable or structural component shell, which is equivalent to the antenna emission effect.

Harmonic current interference

The cause of harmonic current is nonlinear load. Harmonic current interference will affect the waveform of the power supply current and distort it. This interference will cause pollution to the power grid and must be controlled.

LED Power Driver Tester WT2080

The literal translation of EMS (Electro Magnetic Susceptibility) is “Electromagnetic Susceptibility”, which refers to the ease with which electronic equipment is exposed to electromagnetic energy from the outside, which causes its own performance to decline. For example, it is also interfered by a hair dryer or an electric shaver. Snow noise appears on the screen of some TV sets, but some TV sets are safe and sound. This shows that in the case of being “attacked” by electromagnetic interference, the former has higher electromagnetic sensitivity and is more vulnerable to injury, that is, its “defensive power” is lower; while the latter has lower electromagnetic sensitivity and is less likely to be injured, that is “defensive power” will higher.

Electrostatic discharge anti-interference ability

The human body is charged with static electricity. This phenomenon is more serious in the dry winter. Friction in this environment can easily find that the human body carries a large amount of static electricity. At this time, if the human body touches the LED product or its neighboring equipment, it will be directly or indirectly the discharge, the pulse voltage generated may cause the breakdown of the LED, so there are very high requirements for the antistatic ability of the LED products.

EFT Immunity Measurement

The opening and closing of the relay or the on and off of the product will also cause interference to other electronic devices in the same circuit. It has the characteristics of pulse group appearance, high pulse repetitive occupancy rate and short rise time of pulse waveform.

Anti-interference ability of lightning surge generator

Lightning strikes form high-energy surge voltages and currents on the cables, which can easily cause damage to the devices. In addition, the large-scale switch switching moment will also form surge voltage and current on the power supply line.

Voltage Dips and Interruptions Generator

Voltage dips, short-term interruptions and voltage changes are collectively referred to as voltage dips and interruptions generator. The resistance index of cyclic drop interference assesses whether the LED lighting device has the ability to work in an unstable power grid.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618917996096

Your email address will not be published. Required fields are marked *