Switches

MANUALLY OPERATED MECHANICAL SWITCHES which

-control currents exceeding 0,2 A r.m.s. a.c. or d.c., and/or

– have voltage across the open switch contacts exceeding 35 V (peak) a.c. or 24 V d.c. shall meet one of the following requirements:

a) The switch tested as a separate component, shall comply with the requirements and tests of IEC 61058-1, whereby the following applies:

– the number of operating cycles shall be 10 000 (see 7.1.4.4 of IEC 61058-1:2000);

– the switch shall be suitable for use in a normal pollution situation (see 7.1.6.2 of IEC 61058-1:2000);

– deviating from 13.1 of IEC 61058-1:2000, for a.c. and d.c. MAINS SWITCHES built in CRT TV’s, the speed of contact making and breaking shall be independent of the speed of actuation.

NOTE Reason is the high inrush current due to the degaussing coil.

– MAINS SWITCHES shall comply with the flammability category V-0 or according to G.1.1 of Annex G.

The characteristics of the switch with regard to:

– the ratings of the switch (see Clause 6 of IEC 61058-1:2000);

And the classification of the switch according to:

nature of supply (see 7.1.1 of IEC 61058-1:2000), type of load to be controlled by the switch (see 7.1.2 of IEC 61058-1:2000),

ambient air temperature (see 7.1.3 of IEC 61058-1:2000); shall be appropriate for the function of the switch under normal operating conditions.

Compliance is checked according to test specifications of IEC 61058-1, by inspection and by measurements.

If the switch is a MAINS SWITCH which controls MAINS socket-outlets, the total rated current and the peak surge current of the socket-outlets as specified in 14.7.5 shall be taken into account for the measurement.

GNGPL I19_AL

b) The switch tested as part of the apparatus working under normal operating conditions, shall meet the requirements of 14.7.2, 14.7.5 and 20.2.5, and moreover:

– switches controlling currents exceeding 0,2 A r.m.s. a.c. or d.c. shall meet the requirements of 14.7.3 and 14.7.4 if the voltage across the open switch contacts exceeds 35 V (peak) a.c. or 24 V d.c.;

– switches controlling currents exceeding 0,2 A r.m.s. a.c. or d.c. shall meet the requirements of 14.7.3 if the voltage across the open switch contacts does not exceed 35 V (peak) a.c. or 24 V d.c.;

– switches controlling currents up to 0,2 A r.m.s. a.c. or d.c. shall meet the requirements of 14.7.4 if the voltage across the open switch contacts exceeds 35 V (peak) a.c. or 24 V d.c.; and

-MAINS SWITCHES shall comply with G.1.1 of Annex G.14.7.2

A switch tested according to 14.7.1 b) shall withstand, without excessive wear or other harmful effects, the electrical, thermal and mechanical stresses that occur during intended use.

Compliance is checked according to 13.1 of IEC 61058-1:2000, and by the following endurance test:

The switch is subjected to 10 000 cycles of operation with a sequence according to 17.1.2 of IEC 61058-1:2000,excluding the increased-voltage test at accelerated speed specified in 17.2.4 of IEC 61058-1:2000, and under electrical and thermal conditions given by the normal operating conditions of the apparatus.

The test is made on three specimens, no failure is allowed.

A switch tested according to 14.7.1 b) shall be so constructed that it does not attain excessive temperatures during intended use. The materials used shall be such that the performance of the switch is not adversely affected by the operation during intended use of the apparatus. In particular, the material and design of the contacts and terminations shall be such that their oxidation or other deterioration does not adversely affect the operation and performance of the switch.

Compliance is checked in the on-position under normal operating conditions and according to 16.2.2.d), 1) and m) of IEC 61058-1:2000, taking into account the total rated current I of MAINS socket-outlets, if any, and the peak surge current according to 14.7.5.

The temperature rise at the terminations shall not exceed 55 K during this test.

A switch tested according to 14.7.1 b) shall have adequate dielectric strength.

Compliance is checked by the following tests:

The switch shall withstand a dielectric strength test as specified in 10.4, without being previously subjected to the humidity treatment, the test voltage being decreased to 75 % of the corresponding test voltage specified in 10.4, but not less than 500 Vr.m.s. (700 V peak).

– The test voltage is applied in the on-position between HAZARDOUS LIVE parts and ACCESSIBLE conductive parts or parts which are connected to ACCESSIBLE conductive parts, and in addition between the poles in case of a multipole switch.

– The test voltage is applied in the off-position across each contact gap. During the test, resistors, capacitors and RC-units in parallel to a contact gap may be disconnected.

If the switch is a MAINS SWITCH which controls MAINS socket-outlets, the endurance test is carried out with an additional load connected to the socket-outlets, consisting of the circuit shown in Figure 9 of IEC 61058-1:2000, taking into account Figure 10 of

IEC 61058-1:2000.

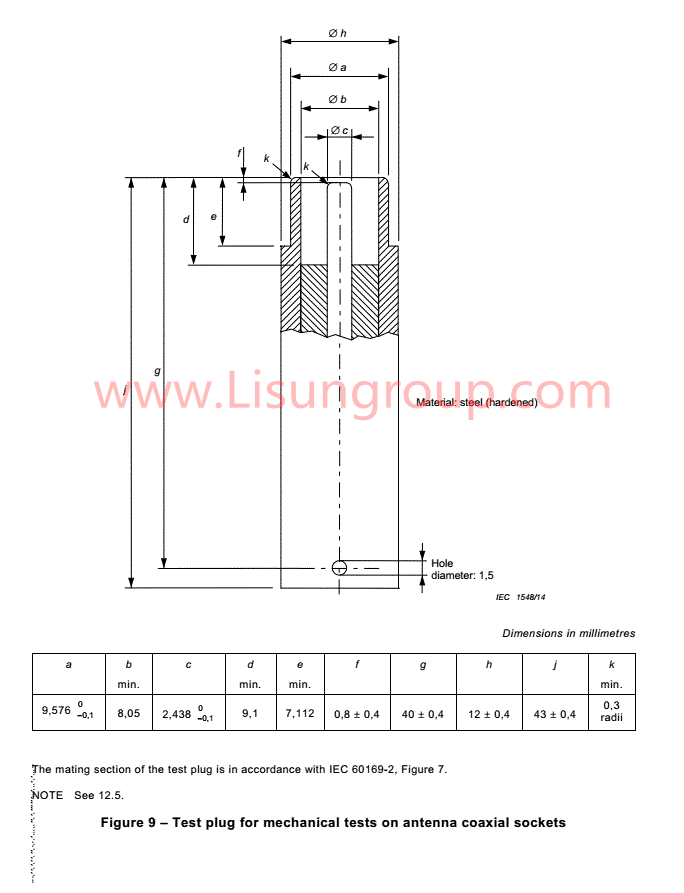

IEC60065 Figure 9

The total rated current of the additional load shall correspond to the marking of the socket- outlets, see 5.3 c). The peak surge current of the additional load shall have a value as shown in Table 14.

After the test, the switch shall show no damage in the sense of this standard. In particular, it shall show no deterioration of its enclosure, no reduction of CLEARANCES and CREEPAGE DISTANCES and no loosening of electrical connections or mechanical fixings.

Compliance is checked by inspection and by the tests specified in 14.7.3 and/or 14.7.4 in the given order.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *