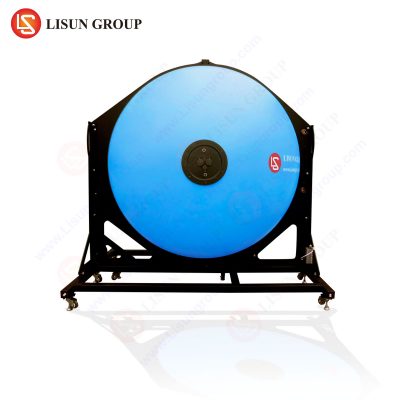

An integrating sphere makes it easy to measure samples. Integrating sphere measurements can be taken for different samples. This article will explain integrating sphere and the processes of taking measurements using LISUN’s Integrating sphere.

The Ulbricht sphere is another name for integrating sphere. The Ulbricht sphere takes after Richard Ulbricht. He is a German engineer. He made photometric measurements to find the ideal lighting approach.

It happened while prepping a train station’s electrical and lighting. He demonstrated that the amount of light measured on the opposite sphere wall from the light source is proportionate to the overall amount of light flow. It got its name from its spherical shape. Sphere lighting systems that use spheres to measure light sources like lamps and luminaries.

Light-scattering or refracting samples are typically tested with a sphere lighting system e.g., Optical lenses. The test method determines the transmission of lenses that condense light after it has passed through the lens. When a standard detector detects light it strikes the detector’s light-sensitive surface.

This concludes the baseline correction (100 percent alignment). After irradiating the sample the light emerges from the detector’s light-sensitive surface. This makes precise measurement impossible. A dispersed sample isn’t measured. All measuring lights aim at the detector’s light-sensitive surface.

Integrating sphere measurements for fiber are taken by replacing the sensor’s front flange with a fiber optic adapter. This is so that the integrating sphere can easily measure fibers. The first reflection spot on the opposite side of the source is not highly concentrated because the typical optical fiber output is slowly diverging.

It results in collimated or divergent beam configurations. The divergent beam having increased NA of the fiber demands configuration in the case of lensed fiber. Configuration is also recommended when using a fiber collimator.

The LISUN integrating sphere can measure transmittance from a sample held in the entrance port. The sample is irradiated. The results are compared to a direct source measurement that excludes the sample. A baffle protects the detector from non-integrated transmission.

The sample being too close to the input port results in the measurement to be affected. Remove the sample from the entrance port if you’re only interested in the narrow angle transmission integrating sphere measurements.

Baseline correction is performed without a sample present at the aperture of the integrating sphere. A standard sample (e.g., a white board filled with barium sulphate) is placed at an aperture on the reflection side of the integrating sphere. Regular transmittance measurements consider both the scattered and linear components that have passed through the sample.

For integrating sphere measurements in a suspension sample, transmittance measurement can also measure haze (turbidity). The baseline is corrected using the standard sample on the reflection side. The sample is then placed at the aperture with the reflection side open or a light trap (a tube for absorbing linear component light to prevent it from entering the detector) is installed.

Turbidity can be calculated using these measurement values. Measure with the light trap installed or with the reflection side open for a more precise measurement. Then calculate correction using the turbidity “0” measurement value.

The irradiation state of the measurement light on sample can be different. It can cause a slight difference between results of spectrophotometer and haze meter.

After performing baseline correction with the standard sample (e.g., a white board filled with barium sulphate) placed at the position (reflection position) irradiated by the measurement light after it has entered the aperture and passed through the inside of the integrating sphere and the standard sample is replaced at the same position with the sample to be measured and integrating sphere measurements for reflectance are performed.

Reflectance measurement with a LISUN integrating sphere is known as relative reflectance measurement. This is because it measures reflectance with respect to a standard sample. It results in changes in the reflectance of the standard sample (for example, changes over time) affect the measurement value of the sample. The reflectance also changes when the standard sample is changed.

Diffuse reflectance and total reflectance are the two types of reflectance integrating sphere measurements. A normal (0°) measurement light is irradiated on the sample during diffuse reflectance measurement. The diffuse reflectance component diffuses within the integrating sphere while the specular reflectance component exits to the outside of the integrating sphere through the hole through which the measurement light entered.

It results in the diffuse reflectance component to be the only one that is measured.

The measurement light is irradiated at an angle of 8° from the sample’s normal when measuring total reflectance. The diffuse reflectance component is diffused inside the integrating sphere in the same way it is in diffuse reflectance measurement, and the specular reflectance part is diffused inside the integrating sphere as it strikes the integrating sphere’s inner wall. It results in total reflectance to includes both specular and diffuse reflectance.

The light intensity measured with a LISUN integrating sphere is 1/100 to 1/1000 of that measured directly by a detector. As a result, noise increases when measurements are made under the same conditions as when light is received directly by a detector. Increase luminosity to reduce noise. Widening the spectrophotometer slit can help.

The inner wall of spectrophotometer integrating sphere is usually 60 mm in diameter. Some integrating spheres have a 150-mm inner wall diameter. These have a lower aperture ratio and better diffusion properties, so have better integrating sphere measurements.

The intensity of light incident on the detector decreases as the integrating sphere expands, resulting in increased noise. The aperture ratio is the area of the hole in relation to the total area of the integrating sphere, including the inner wall hole.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *