Product No: YWX/Q-010X

The YWX/Q-*X Series Composite Salt Spray Test Chamber (also known as Composite Salt Spray Corrosion Tester) is a high-end environmental simulation equipment specially developed for verifying the corrosion resistance of materials and products in complex environments. Different from traditional single salt spray chambers, this series innovatively integrates four core functions: “salt spray corrosion + damp-heat cycle + hot air drying + standard climate simulation”. It can program and combine multiple environmental working conditions in any order, accurately reproduce the drastically changing scenarios such as “salt spray – humidity – drying – low temperature” in the natural environment, and accelerate the assessment of the durability and reliability of products in complex corrosive environments.

The YWX/Q-*X Series Composite Salt Spray Test Chamber is integrally formed with imported corrosion-resistant PP plates (no welding seams, leak-proof). Equipped with a high-precision temperature and humidity control system and a programmable spray module, it supports basic salt spray tests such as NSS/ASS/CASS. At the same time, it is equipped with intelligent functions such as automatic defogging and real-time data recording, which can meet the high-end needs of various industries for complex environmental corrosion tests. It is a core equipment for product R&D verification, quality control and compliance certification.

Standard:

| Standard No. | Standard Name |

| IEC 60068-2-11:2013 | Environmental testing – Part 2-11: Tests – Test Ka: Salt mist |

| IEC 60068-2-52:2017 | Environmental testing – Part 2-52: Tests – Test Kb: Salt mist, cyclic (sodium chloride solution) |

| ISO 3769:2011 | Metallic coatings – Acetic acid salt spray test (ASS test) |

| ISO 16750-4:2018 | Road vehicles – Environmental conditions and testing for electrical and electronic equipment – Part 4: Climatic loads |

| VDA 233-102:2016 | Cyclic corrosion testing of materials & components in automotive construction |

| GMW 14872:2020 | Cyclic Corrosion Laboratory Test |

| PV 1210:2019 | Corrosion Test (Volkswagen Standard) |

| VCS 1027-1449:2018 | Accelerated Cyclic Corrosion Test (General Motors Standard) |

| GWT A H01-03_516:2021 | Corrosion Test for Automotive Components (Ford Standard) |

| GB/T 2423.17-2021 | 环境试验 第 2 部分:试验方法 试验 Ka:盐雾 |

| GB/T 2423.18-2021 | 环境试验 第 2 部分:试验方法 试验 Kb:盐雾,交变(氯化钠溶液) |

| GJB 150.11A-2009 | 军用装备实验室环境试验方法 第 11 部分:盐雾试验 |

| GB/T 10125-2021 | 人造气氛腐蚀试验 盐雾试验 |

| T/CSAE 71-2020 | 汽车零部件及材料循环腐蚀试验方法 |

Note:

There are slight differences in the requirements for composite salt spray test chamber testing among different standards. For specific standards that each model of LISUN composite salt spray test chamber complies with, it is recommended that you confirm with LISUN engineers to accurately match your testing needs.

Specififation:

| LISUN Model | YWX/Q-250X | YWX/Q-750X | YWX/Q-010X | YWX/Q-016X | YWX/Q-020X |

| Working room size | 900*600*500 | 1100*750*500 | 1200*800*500 | 1600*1000*600 | 2000*1000*600 |

| External dimensions | 2160*1100*1300 | 2360*1250*1300 | 2460*1300*1350 | 2860*1500*1450 | 3260*1500*1450 |

| Capacity | 270L | 412L | 480L | 960L | 1200L |

| Solution tank volume | 25L | 30L | 30L | 35L | 40L |

| Pure water tank volume | 30L | 35L | 35L | 40L | 50L |

| Working power | Three Phase AC 380V/50HZ (60Hz is optional) | ||||

| 10.0KW | 12.0KW | 12.5KW | 16.0KW | 18.5KW | |

| Sample space available | 700*450*250 | 900*600*300 | 1000*600*300 | 1400*800*350 | 1800*800*350 |

| Opening Method | Manually control | Stainless steel air spring support | Cylinder support | ||

| Working environmental temperature requirements | The ambient temperature is 5℃~30℃. Ventilation is recommended. When the temperature exceeds 30℃, it is recommended to adjust the room temperature through appropriate methods. | ||||

| Working environment humidity requirements | Environmental humidity below 85%Rh | ||||

| The temperature range of the salt spray chamber | 15℃~65℃ | ||||

| The temperature range of saturated barrel | RT (room temperature) ~ 70 ℃ | ||||

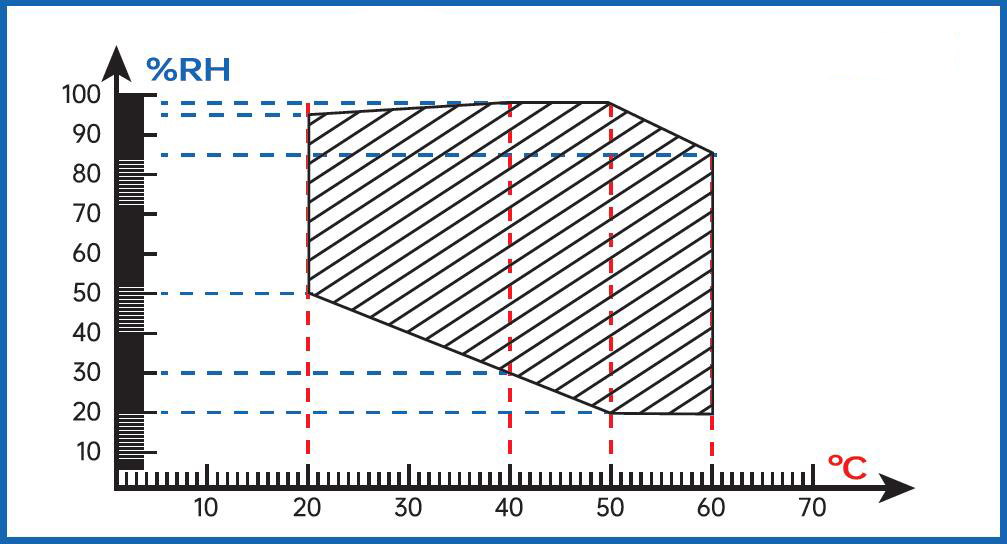

| Relative humidity of the salt spray chamber | 30%-98%RH (± 3%, adjustable, refer to the temperature and humidity corresponding chart) | ||||

| Temperature performance | Temperature uniformity: ≤2 ℃ Temperature volatility: ≤ ± 1 ℃ | ||||

| Salt spray deposition rate | 1-2ml/80cm²/h | ||||

| Test methods | Programmable spray, moist heat, dry, standard climate | ||||

| Test conditions | A. Saline spray test: NSS * test: 35 ℃ ± 2 ℃ * Saturated air barrel: 47 ℃ ± 2 ℃ | ||||

| B. humidity and heat test: 1. Test temperature range: 20 ℃ -60 ℃. 2. Test humidity range: 60%RH ~ 98%RH can be adjusted. | |||||

| C. Dry test: 1. Test temperature range: 20 ℃ ~ 60 ℃. 2. Test humidity range: 30%RH ~ 60%RH can be adjusted. | |||||

| Standard accessories | 1 set of V -type/O -type storage racks, 1 glass nozzle, 2 bottles of sodium sodium (500g/bottle), 1 plastic rust barrel (5L ) | ||||

Optional suggestions: When using LISUN YWX/Q-010X Composite Salt Spray Test Machine, it is necessary to choose a LISUN LS-EU800W2-55L air compressor (power 800W*2, capacity 55L, speed 1380r/min, pressure 0.7Mpa, flow 120L/m in, 220~240V/50Hz) or LS-US800W2-55L air compressor (power 800W*2, capacity 55L, speed 1380r/min, pressure 0.7Mpa, flow 120L/min, 110~120V/60Hz).

LS-EU800W2-55L Air Compressor

Typical Applications:

1. Automotive Industry: Cyclic Corrosion Verification for Vehicle Components

As a core testing equipment in the automotive industry, it meets the standards of major original equipment manufacturers (OEMs) such as Volkswagen (PV 1210), General Motors (VCS 1027-1449), and Ford (GWT A H01-03_516), simulating the alternating environment of “salt spray – damp heat – drying”.

• Test Objects: Body frames, chassis components (suspension/exhaust pipes), door assemblies, lamp housings, electronic sensors (e.g., radar/cameras), and metal-plated parts (e.g., bolts/connectors).

• Test Purpose: Verify the corrosion resistance of components under conditions such as winter deicing agents and coastal humid climates, preventing functional failures caused by coating peeling and structural rust. It complies with standards including ISO 16750-4 and VDA 233-102.

2. Military & Aerospace Industry: Severe Environmental Adaptability Testing

To meet the high reliability requirements of military equipment and aerospace materials, it can reproduce extreme environments such as coastal areas and high salt spray.

• Test Objects: Military electronic components (radar accessories/communication modules), aerospace parts (cabin connectors/landing gear coatings), and metal components of special vehicles.

• Test Purpose: Ensure the structural integrity and stable electrical performance of equipment in complex battlefield environments. It complies with military standards such as GJB 150.11A and is compatible with MIL-STD-202H.

3. Construction & Building Materials Industry: Weather Resistance Testing for Outdoor Materials

It simulates the cyclic outdoor environment of “salt spray – rain – sunlight exposure” that building materials are exposed to for a long time.

• Test Objects: Aluminum alloy profiles (doors, windows/curtain walls), stainless steel decorative parts, architectural coatings (exterior wall paints/anti-corrosion coatings), and hardware connectors (hinges/screws).

• Test Purpose: Evaluate the durability of materials in coastal buildings and industrial pollution areas, avoiding appearance damage and structural safety hazards caused by corrosion. It complies with standards including GB/T 10125-2021 and ISO 3769.

4. Electrical & Electronic Industry: Reliability Verification in Complex Environments

For electrical equipment used outdoors or in humid environments, it assesses their resistance to salt spray and alternating temperature-humidity conditions.

• Test Objects: Outdoor distribution boxes, communication base station enclosures, solar photovoltaic module frames/junction boxes, motor terminals, and outdoor LED lamps.

• Test Purpose: Prevent short circuits and reduced insulation performance caused by salt spray intrusion, ensuring long-term stable operation of equipment in scenarios such as coastal areas and industrial zones. It complies with standards including IEC 60068-2-52 and GB/T 2423.18.

5. Surface Treatment & Coating Industry: Accurate Performance Evaluation of Coatings

Through multi-condition cyclic testing, it quantifies the protective effect of coatings in complex environments.

• Test Objects: Automotive electrophoretic coatings, industrial powder coatings, hardware electroplated layers (zinc plating/nickel plating), and furniture paint samples.

• Test Purpose: Detect defects such as blistering, peeling, discoloration, and rust on coatings, evaluate their adhesion and corrosion resistance, and provide data support for coating formula optimization and quality control. It complies with ISO 3769 and is compatible with ASTM B368.

6. Laboratories & Third-Party Testing Institutions: R&D and Compliance Certification

As a high-end environmental simulation equipment, it provides scientific support for research and development (R&D) and testing.

• R&D Scenarios: Compare the resistance of different materials and coatings to complex corrosion, assisting in the structural optimization of automotive and military products.

• Compliance Certification: Provide enterprises with test data that meets international and domestic standards, supporting product exports (e.g., CE, UL certification) and access to OEM supply chains (e.g., supplier audits by Volkswagen and General Motors), covering the requirements of a full range of standards.

Test Principle:

Composite Salt Spray Test Machine is composed of the cyclic corrosion test of the spray process, the damp and heat process, and the standing and drying process. The following are the schematic diagrams of these three processes:

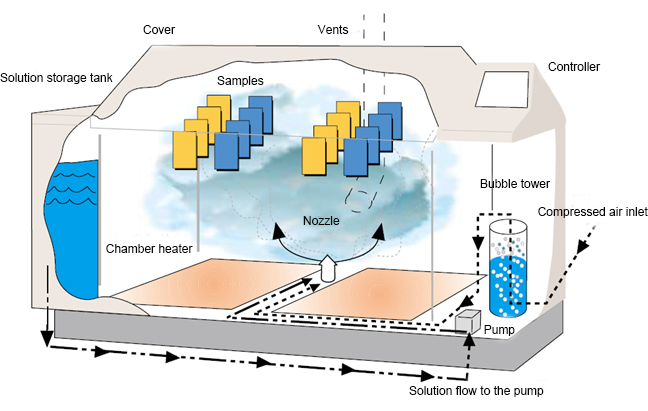

1. Spray process

The system consists of salt water tank, pneumatic system, salt water storage tank, spray tower, nozzle, etc. The salt solution flows from the outside to the test chamber by using the natural drop, and the salt solution is atomized by compressed air through the spray nozzle.

Figure 1 Schematic diagram of the spray process

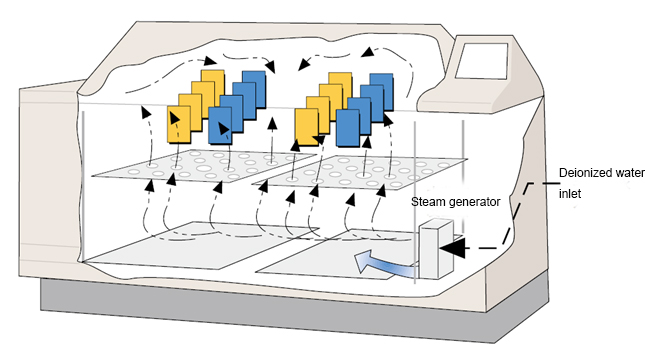

2. Damp heat test

The damp heat test system is composed of steam generator, blast, water circuit, condensation device, etc. After the salt spray test, the machine will set up a defogging program to discharge the salt spray out of the test room as soon as possible; Then the water evaporator will output the appropriate temperature and humidity according to the temperature and humidity set by the controller. Generally speaking, the humidity will be more accurately calibrated and constant after the temperature is stable. The temperature and humidity parameters of the damp heat test are as follows: Temperature: 30℃—60℃; humidity: 80%RH—98%RH.

Figure 2 Schematic diagram of damp heat test

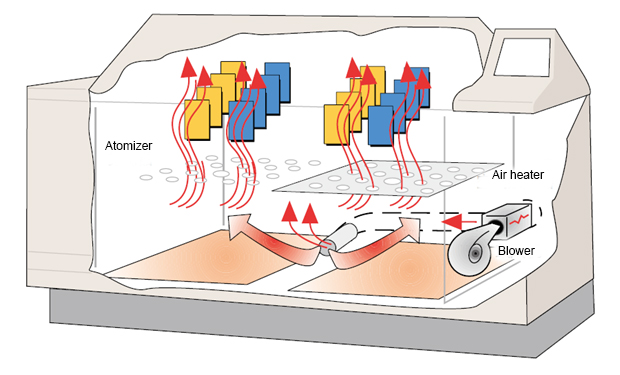

3. Drying process

Standing and drying system adds drying blower, heating wire, air filter and other devices on the basis of damp heat system, if need to simulate standard atmospheric pressure environment test (temperature 23℃±2℃, humidity 45%~55% RH). Firstly, quickly remove the damp and heat test environment in the previous section by setting a defogging program to create a relatively clean test environment, and then the humidifier or dehumidification system works in coordination under the controller to produce an environment that meets the test requirements. The temperature and humidity parameters of the drying test are as follows: temperature: 20℃-60℃; humidity: 30%~60%RH (corresponding to the appropriate temperature point).

Figure 3 Principle diagram of drying process

Appendix: Controllable Temperature and Humidity Ranges of the Composite Salt Spray Test Chamber

Temperature And Humidity Corresponding Chart