Product No: TPB-UL935

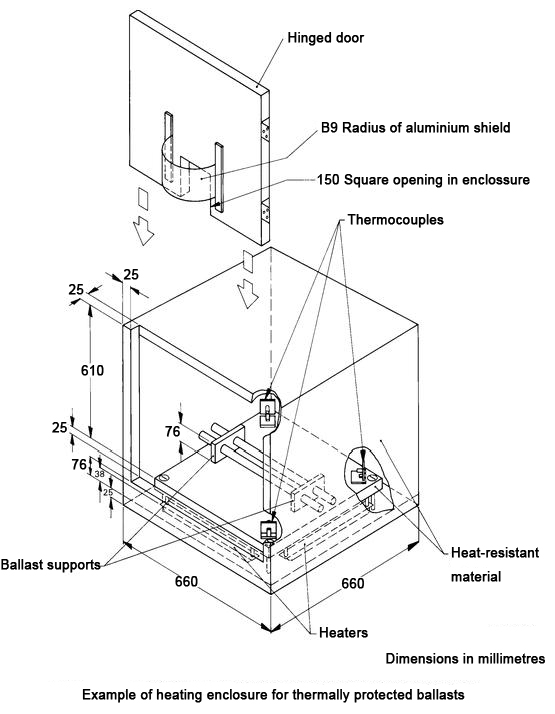

The TPB-UL935 Thermally Protected Ballast Heating Test Chamber is a high-temperature environment simulation device designed by LISUN specifically for electronic and electrical components such as lamp ballasts. The function is to accurately replicate natural high-temperature scenarios, verifying the thermal protection performance and high-temperature adaptability of ballasts and other components through a stable, controllable temperature environment. The equipment utilizes high-grade stainless steel inner and outer chambers and ultra-fine glass wool insulation, along with multiple dedicated strip heaters, enabling wide temperature control from room temperature + 10°C to 100°C.

The TPB-UL935 Thermally Protected Ballast Heating Test Chamber also features three switchable temperature measurement points for real-time monitoring of temperature changes at different locations during testing. It is widely used for pre-shipment thermal protection verification of ballasts, high-temperature performance optimization during the R&D phase, and high-temperature environmental testing for compliance certification. It effectively ensures the safe operation of ballasts in high-temperature conditions and avoids safety risks such as fires caused by thermal protection failure.

Standards:

| Standards No. | Standards Name |

| IEC 61347-1:2024 | Lamp controlgear – Part 1: General and safety requirements |

| UL 935:2007 | Standard for Fluorescent Lamp Ballasts (with Class P Thermal Protection) |

| GB 19510.1-2023 | 灯的控制装置 第 1 部分:一般要求和安全要求 |

Specifications:

| Parameters | Specifications |

| Internal size (L*W*H) | 610mm*610mm*610mm (suitable for most specifications of ballasts, meeting batch or single sample testing needs) |

| Temperature range | RT+10℃~+100℃ (RT is room temperature, covering the typical temperature range of ballast high temperature adaptability test) |

| Temperature uniformity | ≤±2℃ |

| Temperature fluctuation | ≤±0.5℃ |

| Inner and outer box material | High-grade stainless steel plate (corrosion-resistant and high-temperature-resistant, to prevent aging or rust of the box from affecting the test accuracy) |

| Insulation material | Ultra-fine glass wool insulation material (excellent thermal insulation performance, reduces heat exchange between inside and outside the box, and reduces energy consumption) |

| Sample rack configuration | Special wooden test sample rack (good insulation, avoids heat conduction interference from metal racks, and is suitable for placing ballasts of different sizes) |

| Heater type | Special strip heater (size 300mm*40mm, power 300W per group) |

| Number of heaters and connection method | There are 4 groups in total, with power supply connected in parallel (the temperature rises quickly, a single group failure does not affect the overall test, improving equipment reliability) |

| Temperature measurement point | Three temperature measurement points (can be switched at any time to meet the temperature monitoring needs of different locations, such as sample surface and box environment) |

| Temperature control method | Intelligent PID temperature control system (automatically adjusts heating power, accurately maintains set temperature, and supports temperature curve recording) |

| Safety protection | Over-temperature protection (automatically cuts off heating power when the temperature exceeds the set upper limit), overload protection (avoids safety problems caused by heater failure) |

| Observation and operation | Equipped with high temperature resistant glass observation window (for real-time observation of sample status) and touch operation panel (for convenient temperature setting and data reading) |

| Power supply | AC 230V±10%, 50/60Hz, total power ≤1200W |