Ozone test purpose:

Ozone Test Chamber (or called Ozone Aging Chamber and Ozone Aging Test Chamber) is design according to rubber being sensitive characteristic of to ozone, it simulate the environmental to accelerate the rubber aging process by ozone. It compared to different products(test sample) aging result each other according to the same ozone aging test conditions/standards, and get to comparable aging resistance performance.

Test process:

The ozone aging test is expose the test sample at the closed, non-illuminated constant ozone concentration air and constant temperature test box. The sample is tested at predetermined time, to evaluate ozone aging resistance through the sample’s cracks degree or other measured performance change. Ozone aging included static tensile test and dynamic tensile test. The ozone concentration, temperature, humidity, and sample tensile ratio are very important parameters in this aging test.

Application standards:

• GB/T7762-2014 Ozone Aging Resistance Test of Vulcanized Rubber – Static Tensile Test Method;

• GB/T13642-2015 Ozone Aging Resistance Test of Vulcanized Rubber – Dynamic Tensile Test Method;

• ASTM1149 Standard Test Methods for Rubber Deterioration – Cracking in an Ozone Controlled Environment;

• ASTM D3041-79 Method of Testing Coated Fabrics-Ozone Cracking in a Chamber;

• ASTM D1171-18 Standard Test Method for Rubber Deterioration—Surface Ozone Cracking Outdoors;

• ISO1431-1 and ISO1431-3 Rubber, vulcanized or thermoplastic – Resistance to ozone cracking;

Q1: Can I keep the water tank empty if I don’t need to do humidity test?

A1: If there is no water in the water tank, the chamber will alarm and cannot start the test. Whether you do a humidity test or not, you need to add water to the water tank. The ozone generated during the test also needs to be discharged into the water and dissolved after the test.

Add water to the water tank of the ozone chamber/span>

Q2: Things to note about humidity testing

A2:1) Need to add enough water to the water tank no matter you do or don’t do humdity test.

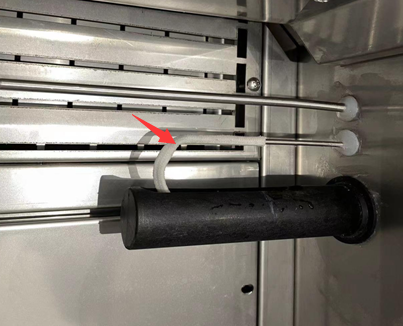

2) The white gauze in the picture below is a wet-bulb gauze. If you don’t need to do humidity test, please remove it to prevent the gauze from drying and hardening during a high-temperature test, which will reduce its water absorption performance. If you need to do a humidity test, put it as shown in the figure below, with the upper end on the humidity sensor and the lower end immersed in the water tank.

3) If there is a problem with the humidity display, please check whether the gauze is still normal. You may need to replace the gauze.

Humidity sensor

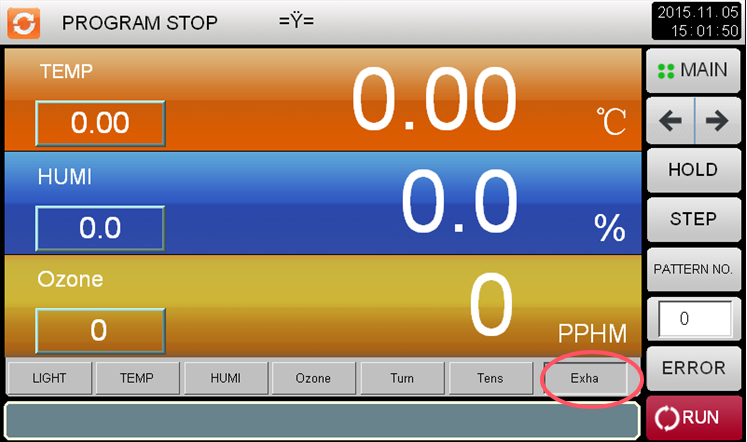

Q3: How and when to exhaust the ozone?

A3: Inhaling ozone is harmful to the human body, so it is necessary to exhaust the waste before opening the door. However, whether it is a fixed value test or a program test, it is not necessary to exhaust the waste during the test, otherwise it will affect the test.

If it is a fixed value test, after the formal test is completed, run a separate exhaust for no less than 5 minutes. If it is a program test, add a 5-minute exhaust segment at the end of the program.

Exhaust the Ozone

Q4: Where will the ozone generated during the test be exhausted?

A4: Ozone cannot be exhausted into the outside air at will, as it will cause pollution or harm to the human body. After the test is completed, when you do “Exhaust”, the ozone will be exhausted into the water in the water tank and dissolved.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *