This client is a private testing institution in Indonesia. As the country’s first national private laboratory to carry out SNI (Indonesian National Standard) testing for children’s toys, it has obtained certification from the Indonesian National Accreditation Committee (KAN) since its establishment in 2013, fully demonstrating its unremitting pursuit of technical excellence and compliance.

The institution provides high-standard physical, mechanical, chemical, and electrical testing services to fully ensure the safety of products across various industries. Relying on a professional and experienced team, it is committed to becoming a trusted independent laboratory, delivering fair and accurate services to domestic and international government agencies, enterprises, and consumers. Its mission is to strictly adhere to government regulations, reduce risks from hazardous substances in products through rigorous testing, safeguard public safety, and build a foundation of trust in the safety and quality of market-circulated goods through innovative solutions.

With the continuous expansion of testing business scope and the increasing variety of test samples, traditional testing methods could no longer meet business development needs. Therefore, the client decided to build a new testing laboratory. After fully understanding the client’s needs and budget, we quickly recommended suitable equipment: the LISUN LSG-1800A High Precision Rotation Luminaire Goniophotometer. Considering the small size of the client’s testing lamps and the existing laboratory space, we particularly recommended the more compact and cost-effective high-precision distributed photometer. Meanwhile, due to budget constraints, we suggested the client choose smaller equipment to ensure it met both economic conditions and practical needs.

After receiving the preliminary proposal, the client made a final decision to purchase after careful consideration and fund preparation. During this period, we provided detailed technical documentation and product introductions to ensure the client fully understood the product performance. To advance the proposal’s implementation, we repeatedly confirmed the darkroom size requirements with the client to ensure the selected equipment perfectly matched the laboratory environment. Once the client finalized the plan, they quickly prepared the funds and placed an order. We immediately initiated equipment production and preparation. At the same time, to coordinate with the laboratory construction schedule, our engineering team provided free darkroom design drawings, saving the client time and laying the foundation for subsequent equipment installation.

To ensure smooth equipment operation, we arranged for LISUN’s professional engineering team to handle installation and training.

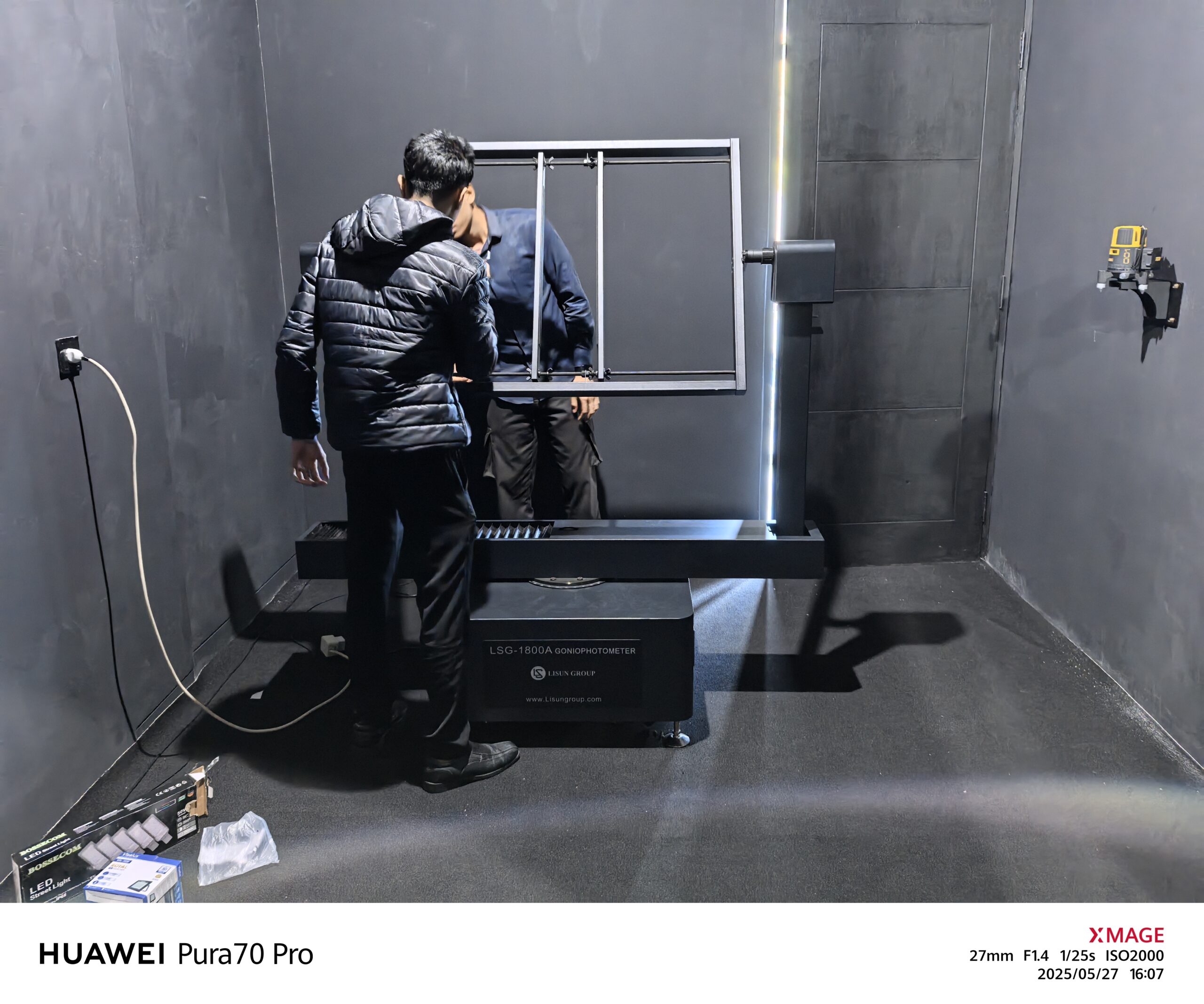

Relying on the company’s after-sales service team based in India, engineers not only explained the equipment operation procedures in detail but also assisted the client in completing preliminary hands-on operations for photoelectric testing. Through professional training, the client quickly mastered equipment usage skills and achieved independent operation. After equipment installation, the client immediately launched testing work and shared on-site photos of the successful installation. The client feedback indicated that LISUN equipment was highly efficient and precise, fully meeting their photoelectric testing needs. With the LSG-1800A High Precision Rotation Luminaire Goniophotometer, the laboratory’s testing efficiency was significantly improved, enabling rapid processing of a large number of test samples. Below are the on-site photos after the client’s successful installation:

Indonesia – LISUN Engineer Provide Installation and Training for LSG-1800A High Precision Rotation Luminaire Goniophotometer

Indonesia – LISUN Engineer Provide Installation and Training for LSG-1800A High Precision Rotation Luminaire Goniophotometer

The successful conclusion of this collaboration not only assisted the client in smoothly establishing their testing laboratory but also further strengthened our company’s professional brand image in the field of electronic testing equipment. We always uphold a customer-centric philosophy and are dedicated to providing high-precision and high-efficiency testing solutions, ensuring that our clients’ products fully comply with market access standards and continuously enhancing their market competitiveness.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *