Product No: SMT-1213

The Test Pin UL 60950-1 Figure 2B is a precision safety tool engineered to verify protection against access to hazardous live parts in Class 0 and Class II information technology (IT) equipment. Its slim 3mm conductive metal probe navigates tight gaps (e.g., USB ports, chassis seams) in devices like laptops or routers, while a 25mm insulating baffle plate prevents over-insertion. Paired with a compact 10mm-diameter insulated handle for control, it applies a controlled 20N thrust to mimic accidental contact with small tools. Designed without cables (for flexible testing setups), it strictly complies with UL and IEC standards, making it critical for IT equipment manufacturers to prevent electric shock and meet global safety rules.

NOTE: Please note SMT-1213 is without cable. If you want to test with Low-voltage Test Supply LISUN model is SMT-529CV, you may choose SMT-1213C with cables.

Specifications:

Tool Type: Test Pin UL 60950-1 Figure 2B

Probe Material: Conductive metal (resistance ≤ 0.1Ω; corrosion-resistant; rigid, no deformation under 20N force)

Handle/Baffle Material: Insulated plastic (handle resistance ≥ 100MΩ; heat-resistant up to 110°C; baffle for over-insertion protection)

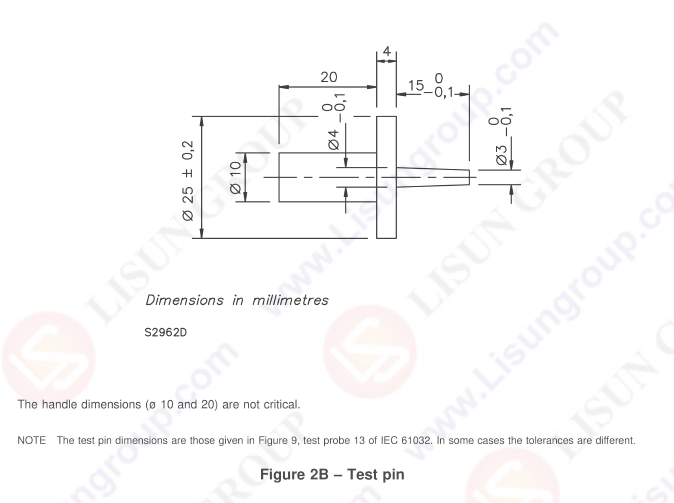

Key Dimensions:

– Test probe diameter: 3 mm

– Test probe length: 15 mm

– Baffle plate thickness: 4 mm

– Baffle plate diameter: 25 mm

– Handle length: 20 mm

– Handle diameter: 10 mm

Applied Thrust: 20N ± 2N (simulates accidental small tool contact; aligns with UL 60950-1 requirements)

Cable Configuration: Cable-free design (compatible with optional low-voltage test supplies for extended functionality)

Core Function: Tests access to hazardous live parts in IT equipment via 3mm probe; blocks over-insertion with baffle; ensures UL/IEC compliance

Test Procedures:

1. Inspect the test pin for bent tips, cracked insulation, or loose baffles; confirm conductivity with a test tool.

2. Power on the IT equipment under test (EUT, e.g., a router) and set it to normal operating mode.

3. Hold the insulated handle, align the 3mm probe with EUT gaps (USB ports, chassis seams, control slots).

4. Apply steady 20N thrust to advance the probe—stop if the 25mm baffle touches the EUT.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if the probe reaches dangerous components.

Applications:

1. Testing USB port gaps in laptop power adapters (per UL 60950-1:2023 Figure 2B) to block access to live terminals.

2. Verifying chassis seams in network routers (compliant with IEC 61032:2017 Figure 9) to prevent contact with internal circuits.

3. Safety checks for monitor power input slots (per IEC 60536:2017) to avoid hazardous part access in Class II IT equipment.

4. Quality control for server power supply units during manufacturing, ensuring UL 60950-1 compliance.

5. Post-production testing of wireless printer control panel gaps to meet global IT equipment safety standards.

Test Pin UL 60950-1 Figure2B S2962D