Product No: SMT-1213C

The EN 61032 Figure 9 Test Probe 13 with Cable is a specialized tool for verifying protection against access to hazardous live parts in Class 0 and Class II electrical equipment. It features a 3mm diameter metal probe (15mm long) for accessing narrow gaps, a 25mm diameter baffle plate (4mm thick) to limit over-insertion, and an insulating handle for user safety. The integrated cable enhances connectivity for testing, while compliance with IEC, CSA, and UL standards ensures reliable results—making it essential for safety checks across consumer electronics, medical devices, and household appliances.

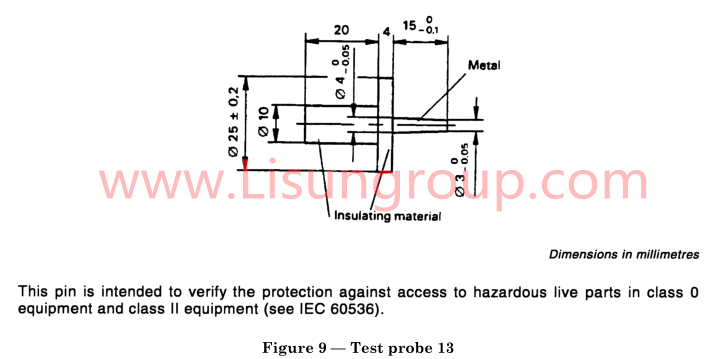

Specifications:

• Probe Dimensions Diameter: 3mm; Length: 15mm (-0.1mm tolerance, ensures precision access)

• Baffle Plate Specifications Diameter: 25mm; Thickness: 4mm (prevents over-insertion into enclosures)

• Handle Dimensions Length: 20mm; Diameter: 10mm (insulating material for user safety)

• Cable Feature: Integrated cable (for enhanced connectivity during testing, supports signal/voltage checks)

• Material Composition Probe: Conductive metal (for reliable contact); Handle/Baffle: Insulating material (flame-retardant)

• bApplicable Equipment Class: Class 0 electrical equipment; Class II electrical equipment (per IEC 60536)

Test Procedures:

• Inspect the probe for damage (e.g., bent metal, frayed cable) and confirm dimensions meet specs.

• Power off the Class 0/II equipment under test and place it on a stable surface.

• Identify potential access points to hazardous live parts (e.g., small gaps in enclosures).

• Hold the insulating handle, align the probe with the access point, and gently insert until the baffle plate touches the equipment surface.

• Check if the probe can contact live parts (via cable connectivity or visual inspection).

• Record results to verify if the equipment meets safety requirements for hazardous part protection.

Applications:

• Safety testing of Class II household appliances (e.g., double-insulated blenders) per IEC 60335-1

• Hazardous part checks for Class 0 audio/video devices (e.g., old-style radios) following IEC 60065

• Quality control for Class II medical devices (e.g., small diagnostic tools) per IEC 60601-1

• Compliance testing for Class 0 IT equipment (e.g., legacy printers) to IEC 60950-1

• Pre-certification checks for hand-held electric tools (e.g., double-insulated drills) per IEC 60745.

Test Probe 13 with Cable with standard EN61032