Product No: SMT-1213

The Test Pin of IEC 62109-1 Figure D.2 is a specialized safety tool engineered for photovoltaic (PV) power conversion equipment—such as PV inverters, combiner boxes, solar charge controllers, and energy storage converters (PCS). It’s designed to test if hazardous live parts (e.g., high-voltage terminals, exposed circuits, or capacitor banks) are accessible through equipment openings, vents, or terminal gaps. Featuring a rigid, precision-machined stainless steel tip (matched to Figure D.2’s exact dimensions) and a heat-resistant insulated handle, it applies a controlled 30N thrust to simulate realistic accidental contact. Strictly compliant with IEC 62109-1 (the global standard for PV safety) and aligned with regional UL rules, it’s critical for manufacturers to ensure solar equipment safety and meet global market access requirements.

NOTE: Please note SMT-1213 is without cable. If you want to test with Low-voltage Test Supply LISUN model is SMT-529CV, you may choose SMT-1213C with cables.

Specifications:

Tool Type: Test Pin of IEC 62109-1 Figure D.2 (for PV power conversion equipment hazardous part testing)

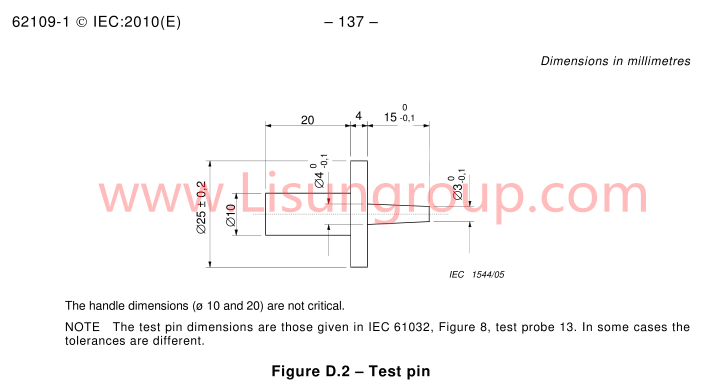

Key Dimensions:

– Test probe diameter: 3 mm

– Test probe length: 15 mm

– Baffle plate thickness: 4 mm

– Baffle plate diameter: 25 mm

– Handle length: 20 mm

– Handle diameter: 10 mm

Core Function: Detects accessible hazardous live parts in PV inverters/combiner boxes; verifies compliance with IEC 62109-1’s safety requirements for solar equipment

Test Procedures:

1. Inspect the test pin for damage (bent tip, cracked insulation, or poor conductivity) using a multimeter to confirm electrical continuity.

2. Power on the PV equipment under test (EUT, e.g., a PV inverter) and set it to its normal operating mode (e.g., grid-connected mode).

3. Hold the insulated handle and align the 6mm probe tip with EUT access points (e.g., vent slots, terminal block gaps, or control panel seams).

4. Apply a steady 30N thrust to the probe, advancing it until resistance from the EUT’s enclosure or internal components stops insertion.

5. Check the connected live-part detection instrument for signals (indicating the probe has contacted hazardous live parts).

6. Record results: Pass if no contact with live parts is detected; Fail if the probe reaches dangerous components.

Applications:

1. Testing vent slot gaps in grid-tied PV inverters (per IEC 62109-1:2021 Figure D.2) to block access to high-voltage DC circuits.

2. Quality control for energy storage converters (PCS) during manufacturing, ensuring compliance with global PV safety standards.

3. Post-production testing of microinverters (used in residential solar systems) to meet regional safety regulations for distributed energy resources.

Test Pin of IEC 62109-1 Figure D.2