Product No: SMT-PB

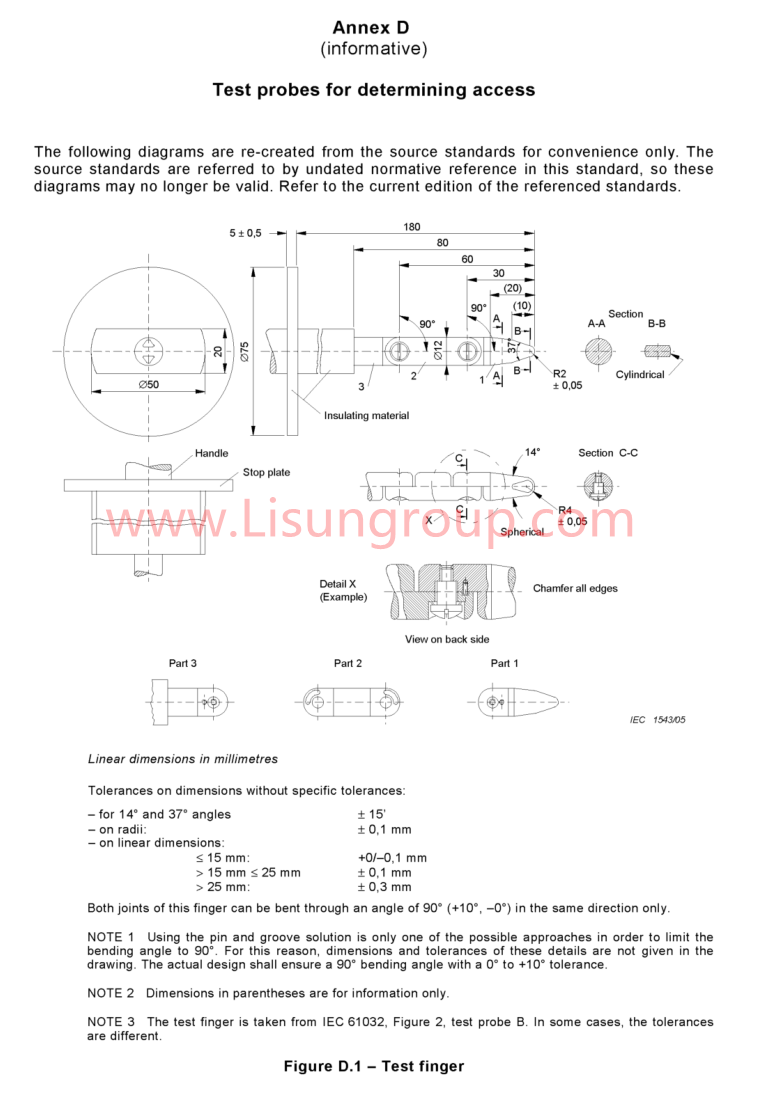

The Test Finger of IEC 62109-1 Figure D.1 is a specialized safety tool tailored for photovoltaic (PV) power conversion equipment—including PV inverters, combiner boxes, solar energy storage systems (ESS), and microinverters. It mimics the shape and flexibility of a human finger (via its articulated joint design) to navigate curved or narrow paths in PV equipment, testing if hazardous live parts (e.g., high-voltage DC terminals, exposed capacitors, or wiring) are accessible. Crafted from conductive stainless steel (for detecting live components) and paired with a heat-resistant insulated handle, it applies a controlled 10N thrust to simulate accidental light contact. Strictly compliant with IEC 62109-1 (the global standard for PV safety), it’s critical for manufacturers to prevent electric shock and meet global solar equipment market requirements.

Specifications:

Tool Type: Test Finger of IEC 62109-1 Figure D.1 (for PV power conversion equipment hazardous part testing)

Knurled Finger Diameter: 12 mm

Knurled Finger Length: 80 mm

Baffle Plate Diameter: 50 mm

Baffle Plate Length: 100 mm

Baffle thickness: 20 mm

Core Function: Navigates PV equipment gaps via flexible joint; detects accessible hazardous live parts; ensures compliance with IEC 62109-1

Test Procedures:

1. Inspect the test finger for damage (loose joint, bent tip, cracked insulation) and confirm conductivity with a test tool.

2. Power on the PV equipment under test (EUT, e.g., PV inverter) and set it to normal operating mode (e.g., grid-connected).

3. Hold the insulated handle, use the joint to guide the probe into EUT gaps (vents, terminal panel seams, or control slots).

4. Apply a steady 10N thrust to advance the probe—stop when resistance from the EUT’s enclosure or components is felt.

5. Check the connected live-part detection instrument for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if live parts are accessible.

Applications:

1. Testing access to high-voltage DC terminals in grid-tied PV inverters (per IEC 62109-1:2021 Figure D.1) to prevent electric shock.

2. Quality control for residential microinverters during manufacturing, ensuring global PV safety compliance.

3. Post-production testing of solar charge controller control panels to meet regional solar equipment safety standards.

Test Finger of IEC 62109-1 Figure D.1