Product No: SMT-PA100A-UZ11

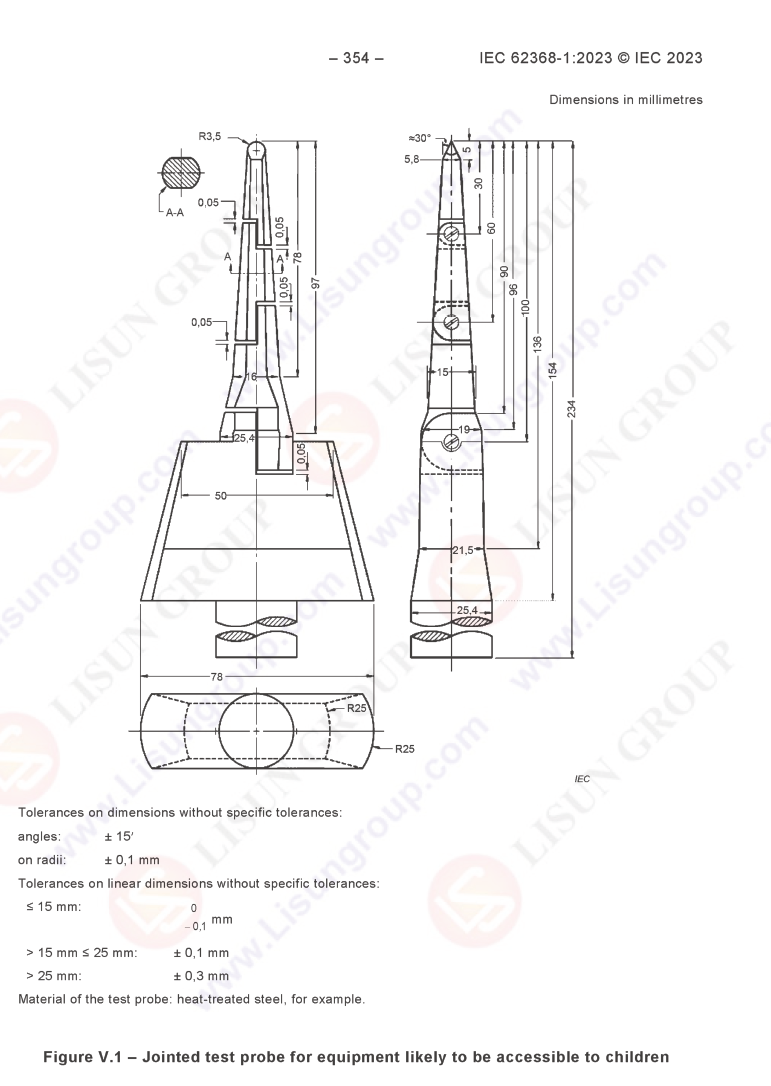

IEC 62368 Figure V.1 Standard Jointed Test Probe and Unjointed Test Probe – both designed to simulate human finger access for testing audio/video (AV) and information/communication technology (ICT) equipment. The jointed probe features two 90°-bendable joints (mimicking natural finger movement) for hard-to-reach gaps, while the unjointed version offers rigid access for straight openings. Both use corrosion-resistant stainless steel for durability and insulating nylon handles for safe grip, applying a precise 10N thrust. Aligned with global safety standards, they ensure hazardous live/mechanical parts stay inaccessible, critical for compliance checks.

Specifications:

• Probe Type : IEC 62368 Figure V.1 Standard Jointed Test Probe and Unjointed Test Probe

• Material:

– Probe Body: Stainless steel

– Handle: Nylon (insulating, non-slip) – Probe Body: Stainless steel

– Handle: Nylon (insulating, non-slip)

• Key Dimensions:

– Probe Diameter: 12 mm ± 0.1 mm

– Effective Length: 80 mm ± 0.2 mm

– Joint Bend Angle: 90° ± 10° (2 joints, same plane)

– Total Length: 180 mm ± 0.5 mm – Probe Diameter: 12 mm ± 0.1 mm

– Effective Length: 80 mm ± 0.2 mm

– Total Length: 180 mm ± 0.5 mm

• Applied Thrust: 10N ± 0.5N (simulates accidental finger pressure) 10N ± 0.5N (simulates accidental finger pressure)

• Core Function: Verifies hazard inaccessibility via curved/angled equipment gaps Verifies hazard inaccessibility via straight equipment openings

Test Procedures:

• Inspect both probes for damage (bent bodies, cracked handles, stuck joints on jointed version).

• Power on the AV/ICT equipment and let it reach normal operating mode.

• For jointed probe: Adjust joints to 90°; for unjointed: Use as-is—align with target openings.

• Apply steady 10N thrust to the probe toward potential hazardous parts.

• Check if either probe touches live components or moving parts.

• Record if the equipment meets safety requirements (pass/fail).

Applications:

• Safety testing of smart TVs (curved vents/joints) and soundbars per IEC 62368-1Figure V.1.

• Compliance checks for laptops (keyboard gaps) and tablets using the unjointed probe.

• Verification of Wi-Fi routers (rear port openings) with the jointed probe for hard-to-reach hazards.

• Quality control for office projectors (lens covers, vent slits) during manufacturing.

• Post-production audits of conference room AV systems (microphones, amplifiers) to meet global standards.

IEC 62368 Figure V.1 Standard Jointed Test Probe and Unjointed Test Probe