RoHS testing is necessary in the current market to check for toxic chemicals. In this article, Let’s explain what RoHS is and why it is so important.

RoHS means Restriction of Hazardous Substances. The European Union developed the RoHS directive to protect humans and the environment from hazardous substances. The RoHS3 Directive called “Directive (EU) 2015/863,” was in effect from July 2019. It excluded medical devices from the requirements. The medical device exemption will expire in July 2021. This means that more testing for materials to show RoHS compliance will be needed. Especially if these products are intended for use in the Eurasian Economic Union (EAEU).

RoHS Testing EDX-2

The RoHS directive limits the use of ten dangerous chemicals in electrical and electronic products:

• Lead (Pb)

• Mercury (Hg)

• Cadmium (Cd)

• Hexavalent Chromium (Cr (VI))

• Polybrominated Biphenyls (PBB)

• Polybrominated Diphenyl Ethers (PBDE)

• Bis(2-Ethylhexyl) phthalate (DEHP)

• Benzyl butyl phthalate (BBP)

• Dibutyl phthalate (DBP)

• Diisobutyl phthalate (DIBP)

RoHS sets maximum concentration values for each of these restricted substances. All are at 0.1%, except cadmium which is at a limit of 0.01%.

It reduces the use of dangerous substances in most electrical and electronic products. The standards come directly from the European Union. This testing is important because the given chemicals are dangerous for the environment.

These chemicals are known for polluting landfills. They are considered harmful because of their exposure during manufacturing and disposal. It is the most important standard procedure for the electrical and electronic part market. It includes equipment sold and used throughout the European Union.

The EU RoHS Directives limit the use of dangerous substances in all electrical and electronic materials. Its examples include medical devices and control and monitoring equipment. This directive ensures substitution and preservation of safer alternatives. It is generally applied on equipment that functions at voltages between 1000 and 1500 volts. These include electric bulbs, household luminaries, medical devices, and control and monitoring equipment.

Different laboratories help customers get RoHS compliant products. They specialize in quick, correct, and reliable RoHS testing. They also check the part materials and look for different levels of restricted substances.

Most of these labs have the technology to assess RoHS harmful chemicals. E.g. lead, mercury, and cadmium, and hexavalent chromium. They must also find the total present amount of Bromine in the compound. It results in aiding to find whether a material follows RoHS requirements.

Some capabilities of the RoHS Compliance Testing laboratories include

• Testing products – the major components in materials of products are tested.

• Assessment of some hazardous chemicals, which include lead, mercury, cadmium, hexavalent chromium, and bromine.

• Several improved testing methods.

Spectroscopy and wet chemistry methods are two common methods used by testing labs. They figure out the concentrations of restricted RoHS samples inside test tubes. RoHS has a certain maximum concentration limit for each restricted substance. These values are typically set at 0.1 percent, except for cadmium, which has a limit of around 0.01 percent.

RoHS is a regulation that applies to electronic products. These include CPUs, ICs, connectors, PCBs, solder, wires, and other electronic components. Coatings, casings, and other non-electrical components are also examples of such products.

As such, RoHS lab testing applies to the following products

• Consumer electronics

• Household appliances

• Machinery

• Quartz watches

• Electronic toys

• AC adapters

• Power tools

Importers and manufacturers ensure compliance. This is done within the specified substance limitations. The most straightforward method for this is third-party lab testing.

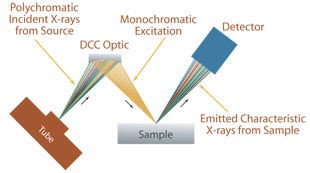

All the elements in the sample are excited at the same time in these spectrometers. The fluorescence radiation emitted by the sample is collected at the same time as well. This is done by an energy-dispersive detector and a multi-channel analyzer. It separates the different energies of the characteristic radiation from each of the different sample elements.

The detector finds the resolution of EDXRF systems within range of 150 eV to 600 eV. EDXRF systems are known for their ease of use, speed of operation, lack of moving parts, and high source efficiency. Such instruments can receive help from X-ray optics. Usual focal spot are at the surface for conventional XRF instrumentation. These range from few hundred micrometers to some millimeters in diameter.

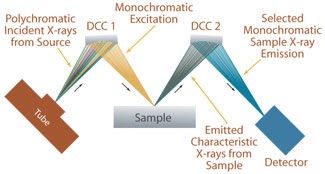

Polycapillary focusing optics get X-rays from a diffracted X-ray source. They direct them to a small and focused beam with diameters as small as tens of micrometers at the sample surface.

The resulting X-ray delivered to the sample in a small focal spot is intense. It allows for improved spatial resolution for small feature analysis. It also improves performance for trace element measurement in Micro EDXRF applications. For enhanced elemental analysis, doubly curved crystal optics direct an intense micron-sized monochromatic X-ray beam to the sample surface.

EDXRF

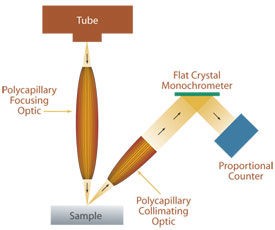

Wavelength dispersive X-ray fluorescence (WDXRF) is another type of instrument for RoHS compliance testing. All the elements in the sample are excited simultaneously in such spectrometers. Different energies of the characteristic radiation are emitted from the sample. They are diffracted into different directions by a monochromator. The intensity of X-rays with a specific wavelength is measured by tilting the detector at a specific angle.

These spectrometers measure the intensities of different wavelengths. Measurements are taken by moving a movable detector on a goniometer through an angular range. Simultaneous spectrometers have a set of fixed detection systems. Each of them measures the radiation of a different element. The main advantages of these systems are high resolution (typically 5–20 eV) and minimal spectral overlaps.

The instrument gets help from X-ray optics. It has a typical focal spot sizes at the surface for conventional XRF instrumentation range. This range is from some hundred micrometers to a few millimeters in diameter. Polycapillary focusing optics get the X-rays from a diffracted X-ray source. They are directed to a small and focused beam. At the sample surface the diameters as small as tens of micrometers.

WDXRF

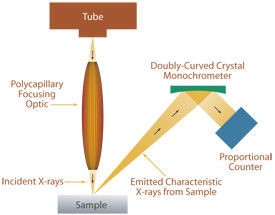

The increased intensity is delivered to the sample in a small focal spot as a result. It provides better spatial resolution for small feature analysis. Improved trace element measurement performance for Micro WDXRF applications is also seen. The sample emits different energies of specific radiations. They are diffracted into different directions by a monochromator. It redirects them as a parallel beam to the analyzing flat crystal for energy dispersion.

A doubly curved crystal monochromator is used to collect and direct selected emitted fluorescence from a sample. This is the opposite of using a polycapillary collimating optic and a flat crystal for fluorescence collection and dispersion. Monochromatic WDXRF is performed using two doubly curved crystal optics. They supply extremely high sensitivity for a specific sample element of interest.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: Service@Lisungroup.com, Cell/WhatsApp:+8615317907381

Sales Dep: Sales@Lisungroup.com, Cell/WhatsApp:+8618117273997

Your email address will not be published. Required fields are marked *