Product No: SMT-PA100A

The UL 507 Figure 9.2 Articulated Probe with Web Stop (PA100A) is a versatile safety tool designed for testing household, commercial, and electronic equipment. It mimics human finger movement via restricted joint motion and a palm simulator, verifying if dangerous live parts, hot components, or mechanical parts are accessible—while blocking solid foreign objects from entering devices. Crafted with a stainless steel test finger (for live-part detection) and a nylon insulated handle (for operator safety), it meets multiple UL standards. This probe is critical for manufacturers to validate anti-shock safety and ensure compliance with global equipment regulations, from electric fans to audio devices.

Specifications:

Standards: UL 507 Figure 9.2; UL 1017:2023 Figure 2; UL 982:2023 Figure 7.1; UL 1082:2023 Figure 7.2

Material: stainless steel and nylon

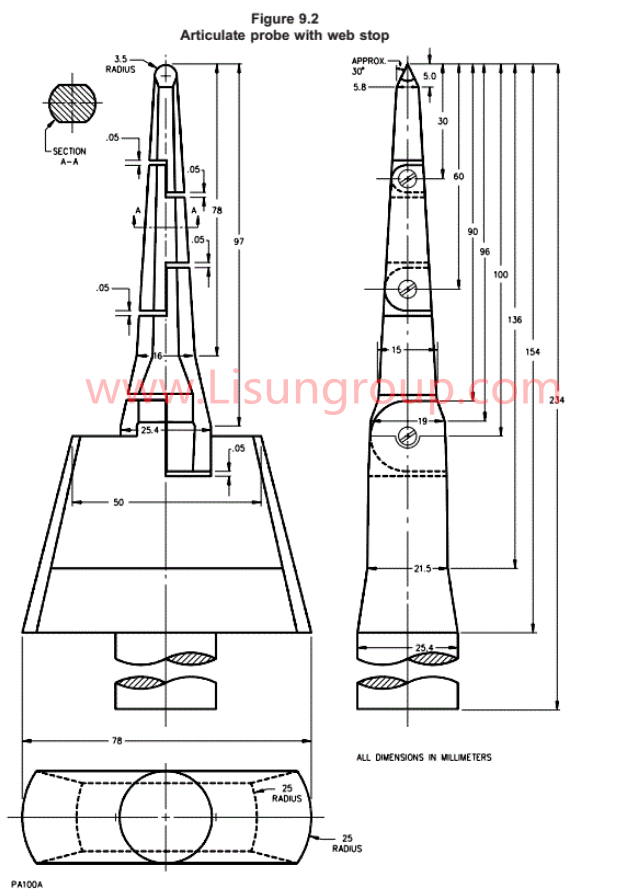

Key Dimensions:

– Test finger diameter:25.4 mm(1 inch)

– Test finger length:101.6 mm(4 inch)

– Head radius: R12.7 mm(1/42 inch)

– Tail diameter:31.75 mm(1-1/4 inch)

Joint Characteristics: Articulated (restricted motion); max bending angle: 90° ± 10° (simulates human finger flexibility)

Applied Thrust: 10N ± 0.5N (simulates accidental human contact; aligns with UL standard requirements)

Core Function: Detects accessible hazardous live/hot/mechanical parts; blocks solid foreign objects; ensures UL compliance across equipment types

Test Procedures:

1. Inspect the probe for loose joints, bent fingers, cracked insulation, or damaged web stops; confirm conductivity with a test tool.

2. Power on the equipment under test (EUT, e.g., electric fan) and set it to normal operating mode.

3. Hold the nylon handle, use the articulated joint to guide the 25.4mm finger into EUT gaps (fan grilles, control panels).

4. Apply steady 10N thrust—stop if the web stop touches the EUT or resistance blocks insertion.

5. Check the connected live-part detector for signals (indicating contact with hazards).

6. Record results: Pass if no contact; Fail if the probe reaches dangerous components.

Applications:

1. Testing fan grille gaps in electric fans (per UL 507:2023 Figure 9.2) to block access to rotating blades and live motors.

2. Verifying vacuum cleaner nozzle seams (compliant with UL 1017:2023 Figure 2) to prevent contact with internal wiring.

3. Safety checks for food processor blade housings (per UL 982:2023 Figure 7.1) to avoid injury from moving parts.

4. Quality control for dehumidifier air vents (per UL 474:2009 Figure 4.1) to ensure no access to hot components.

5. Post-production testing of coffee maker heating element covers (per UL 1082:2023 Figure 7.2) to meet household appliance safety rules.

UL 507 Articulate Probe with Web Stop PA100A UL