Product No: SMT-IP40T

The IEC 61032 Figure 4 Steel Wire with 1N Dynamometer is a precision safety tool designed for testing access to hazardous live parts in ultra-narrow gaps of miniaturized electrical/electronic devices—such as wireless earbud charging ports, smartwatch sensor slots, and medical micro-sensors. Its ultra-thin 1mm stainless steel wire navigates gaps too small for standard probes, while the integrated 1N dynamometer ensures precise, consistent force control (critical for avoiding damage to delicate components). Crafted from corrosion-resistant stainless steel (for conductivity and durability) and paired with a lightweight grip, it strictly complies with IEC 61032, making it essential for manufacturers to validate safety in tiny devices and meet global regulatory requirements.

Specifications:

Tool Type: IEC 61032 1mm Steel Wire with 1N Dynamometer, IP4X Test Probe D

Steel Wire Material: Conductive stainless steel (resistance ≤ 0.1Ω; corrosion-resistant; diameter tolerance: ±0.02mm)

Dynamometer Integrated: 1N capacity; accuracy: ±0.05N; digital display (optional) for real-time force monitoring

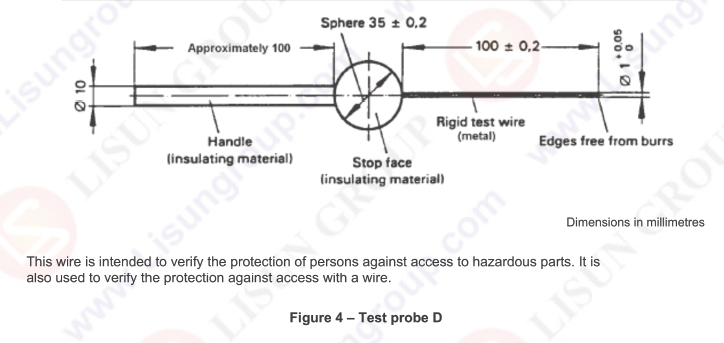

Key Dimensions:

– Wire length: 100 mm

– Wire diameter: 1.0 mm

– Circular-baffle diameter: 35 mm

– Handle diameter: 10 mm

– Handle length: 100 mm

– According to IEC61032 figure 4 (the Test probe D).

– Thrust: 1N

Applied Force: Fixed 1N (controlled by dynamometer; prevents over-force on delicate components)

Core Function: Navigates ultra-narrow device gaps via 1mm wire; detects hazardous live parts with precise 1N force; ensures IEC 61032 compliance

Test Procedures:

1. Inspect the steel wire for kinks, corrosion, or breaks; calibrate the dynamometer to confirm 1N accuracy.

2. Power on the miniaturized device under test (EUT, e.g., earbud charger) and set it to active mode (e.g., charging).

3. Hold the grip, align the 1mm wire tip with the ultra-narrow gap (e.g., charger port crevice).

4. Advance the wire into the gap, using the dynamometer to maintain exactly 1N force.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if live parts are accessible.

Applications:

1. Testing ultra-narrow charging port gaps in wireless earbuds (per IEC 61032 Figure 4) to block circuit access.

2. Quality control for micro-LED display driver board gaps during manufacturing, ensuring IEC compliance.

3. Post-production testing of portable Bluetooth microphone USB-C port seams to meet global safety standards.

IEC 61032 Figure 4 Steel Wire with 1N Dynamometer