Product No: SMT-PA140A

The UL 1278 Figure 8.2 PA140A Probe for Film-coated Wire can be inserted to any depth that the opening allows. It can also be rotated or angled before, during, and after insertion to any necessary position for examining the enclosure.

Specifications:

Probe Type: UL 1278 Figure 8.2 PA140A Probe(for insulation integrity testing in electric tool wiring)

Handle Material: Nylon (fully insulating, heat-resistant up to 100°C; non-slip grip for precise pressure control)

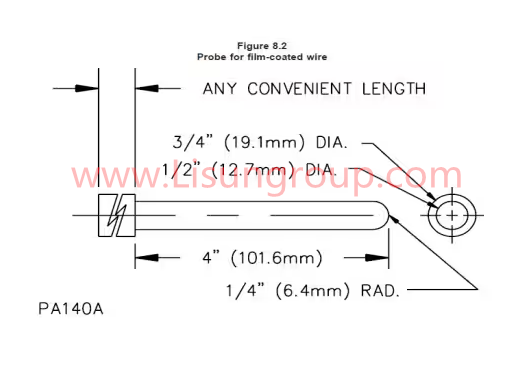

Key Dimensions:

– Total Length: 101.6mm(4 inch)

– Head Diameter: 12.7mm(1/2 inch)

– Former Head Radius: 6.4mm(1/4 inch)

– Tail Diameter: 19.1mm(3/4 inch)

– Standard: UL398 Fig 8.2(PA170B), UL507(PA170D), UL749 Fig 2, UL982 Fig 58.6 and UL1278 Fig 8.2(PA140A)

Test Procedures:

1. Inspect the probe (no bent tip, cracked handle, or poor conductivity) and connect it to a wire leakage detection instrument.

2. Remove the electric tool’s outer casing to access internal enameled wires; ensure wires are clean and dry.

3. Hold the insulating handle and align the 0.8mm brass tip with the enameled wire’s surface.

4. Glide the probe lightly along the wire’s length, focusing on high-stress areas (e.g., near motor connections).

5. Monitor the detection instrument for signals (indicating coating damage and electric leakage).

6. Record defective wire sections and confirm if the tool meets safety requirements (pass/fail).

Applications:

1. Safety testing of enameled wires in hand-held electric drills (per UL 1278:2023 Figure 8.2 ).

2. Verification of sanding tool enameled wires for U.S. retail markets to prevent electric leakage.

3. Quality control for electric screwdriver internal wiring during manufacturing.

4. Post-production audits of cordless rotary tool enameled wires to meet UL 1278 safety standards.

UL 1278 Figure 8.2 PA140A Probe for Film-coated Wire