Product No: SMT-SB0504A

UL 749 Figure 9.2 SB0504A Accessibility Knife Probe is a specialized safety tool designed for testing the accessibility of hazardous parts in industrial control equipment. It features a thin, rigid stainless steel knife-shaped tip – optimized to access narrow gaps and crevices in control panels or enclosures that standard probes can’t reach. Paired with an insulating nylon handle for tester safety, it applies a precise 50N thrust to mimic moderate external force, verifying if live wires or moving components remain out of reach. Strictly aligned with UL 749 requirements, it’s durable, dimensionally stable, and critical for manufacturers to ensure industrial equipment meets U.S. safety compliance.

Specifications:

• Probe Type: UL 749 Figure 9.2 SB0504A Accessibility Knife Probe

• Knife Tip Material: Stainless steel (thin, rigid, corrosion-resistant; maintains sharp edge for gap access)

• Handle Material: Nylon (fully insulating, heat-resistant, non-slip for controlled force application)

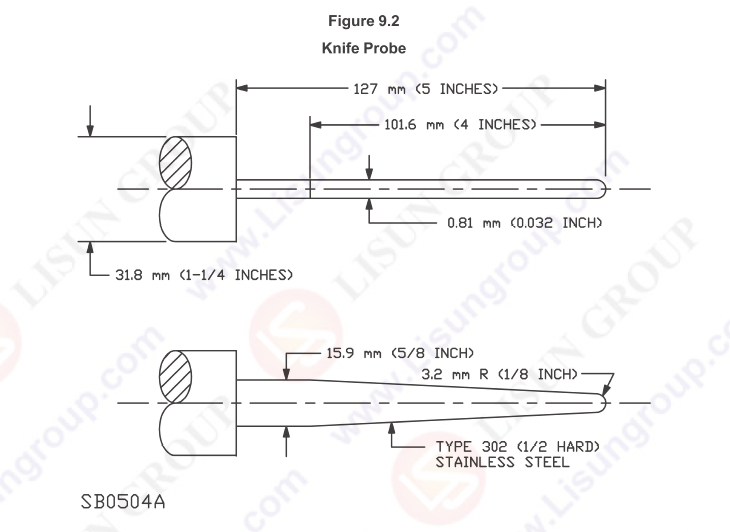

• Key Dimensions:

– Knife Tip Width: 6 mm ± 0.1 mm

– Knife Tip Thickness: 1 mm ± 0.05 mm

– Effective Tip Length: 50 mm ± 0.2 mm

– Handle Length: 130 mm ± 0.5 mm

– Total Length: 180 mm ± 0.5 mm

• Applied Thrust: 50N ± 1N (simulates moderate force on narrow gaps in industrial enclosures)

• Core Function: Verifies accessibility of hazardous live/moving parts in narrow gaps of industrial control equipment per UL standards

Test Procedures:

• Inspect the probe (no bent knife tip, cracked handle, or loose connections) and confirm thrust calibration.

• Power on the industrial control equipment and let it reach normal operating mode.

• Hold the insulating handle and align the knife tip with narrow gaps (e.g., panel seams, button slots).

• Apply steady 50N thrust to the probe—maintain force for 5 seconds (per standard guidelines).

• Check if the tip touches hazardous components (e.g., exposed wiring, relay parts).

• Record whether the equipment meets safety requirements (pass/fail).

Applications:

• Safety testing of industrial control panels (e.g., factory automation controllers) per UL 749:2023 Fig 9.2.

• Compliance checks for motor control centers and switchgear to block narrow-gap access to live parts.

• Verification of non-patient-contact medical auxiliary equipment (e.g., lab sample processors) per UL 61010-1:2023.

• Quality control for industrial sensor enclosures (e.g., temperature/pressure sensors) during manufacturing.

• Post-production audits of automated assembly line control units to meet U.S. industrial safety standards.

UL Accessibility Knife Probe of UL 749 Fig 9.2(SB0504A)