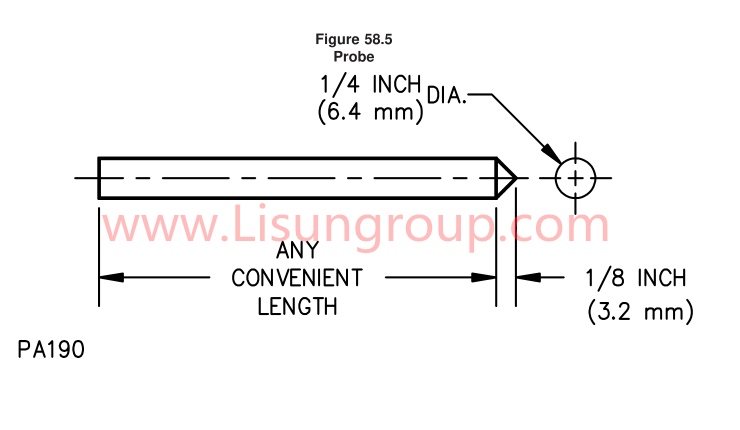

Product No: SMT-PA190

UL 982 Figure 58.5 Test Probe PA190 is a specialized safety tool designed for testing household refrigerators, freezers, and similar cooling appliances, it also fully meet UL 498 Figure 10.1. It features a rigid, precision-machined stainless steel probe tip to simulate accidental insertion into appliance gaps—critical for verifying that hazardous live parts (e.g., wiring, compressors) or moving components (e.g., fan blades) remain inaccessible. Paired with an insulating nylon handle for safe grip, it applies controlled force to match real-world contact scenarios. Strictly aligned with UL 982’s requirements, it’s durable, dimensionally stable, and essential for manufacturers to ensure appliance safety and meet U.S. market compliance.

Specifications:

• Probe Type: UL 982 Figure 58.5 Test Probe PA190 (for refrigerators/freezers)

• Probe Material: Stainless steel (rigid, corrosion-resistant, maintains tip sharpness for precise insertion)

• Handle Material: Nylon (insulating, heat-resistant, non-slip for controlled operation)

• Key Dimensions:

– Probe Tip Diameter: 3.2 mm ± 0.05 mm

– Effective Probe Length: 76.2 mm ± 0.2 mm

– Handle Length: 120 mm ± 0.5 mm

– Total Length: 196.2 mm ± 0.5 mm

• Applied Force: No appreciable force (mimics light, accidental contact with appliance gaps/slots)

• Core Function: Verifies inaccessibility of hazardous live/moving parts in household refrigerators, freezers, and ice makers per UL standards

Test Procedures:

• Inspect the probe for damage (e.g., bent tip, cracked handle) to ensure testing accuracy.

• Power on the refrigerator/freezer and let it reach normal operating mode (including cooling and ice-making functions if applicable).

• Hold the nylon handle and align the probe tip with appliance gaps (e.g., door seals, vent slits, ice dispenser slots).

• Gently insert the probe into gaps, avoiding force that could damage the appliance.

• Check if the probe touches any hazardous components (e.g., internal wiring, fan blades).

• Record whether the appliance meets safety requirements (pass/fail).

Applications:

• Safety testing of household frost-free refrigerators (per UL 982 Figure 58.5) to block access to compressor wiring.

• Compliance checks for chest freezers and upright freezers.

• Verification of built-in kitchen refrigerators with ice dispensers to prevent probe access to moving parts.

• Quality control for compact dorm refrigerators during manufacturing for U.S. retail markets.

• Post-production audits of residential ice makers (standalone or fridge-integrated) to meet UL safety standards.

UL 982 Figure 58.5 Test Probe PA190

Tags:SMT-PA190 , UL 982