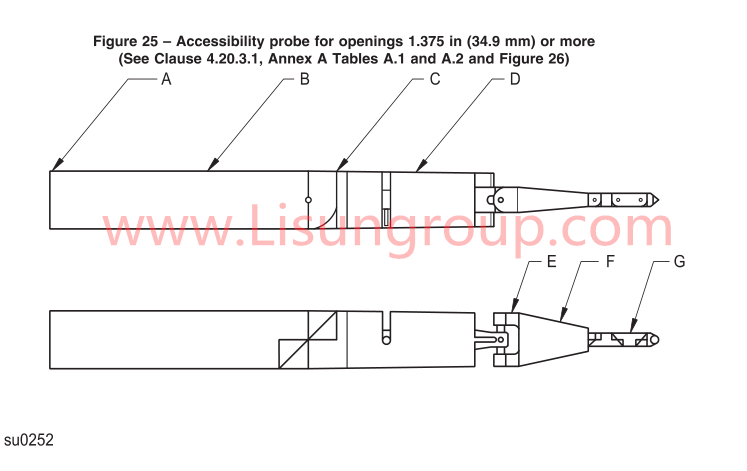

Product No: SMT-SU0252

This accessibility probe is designed and manufactured according to UL1017 : 2018 figure 25 and figure 26, CSA C22.2 No.243-17, etc. Its dimensions apply to the 13-18 month age bracket (male and female). This test probe is used to test whether the simulated arm will touch the running parts (such as rotor, pulley, belt, gear, etc.) inside the vacuum cleaner during normal use. Featuring a rigid, conductive stainless steel tip (matching UL 1017’s precise dimensions) and a heat-resistant insulated handle.

Specifications:

Tool Type: UL 1017 Figure 25 Accessibility Probe (for transformers/power supplies hazardous part testing)

Key Dimensions:

| Upper arm circumference-female-5th percentile | 11.9 cm (4.685 in) |

| Shoulder to elbow length-male-95th percentile | 16.8 cm (6.61 in) |

| Forearm circumference -femae-5th percentile | 12.1 cm (4.76 in) |

| Lower arm length-male-95 percentile | 22.7 cm (8.94 in) (Elbow to finger tip) |

| Minimum hand clearance diameter-female-5th percentile | 3.49 cm (1.374 in) |

| Hand length-male-95th percentile | 10.2 cm (4.016 in) |

| Middle finger length-male-95th percentile | 4.5 cm (1.772 in) |

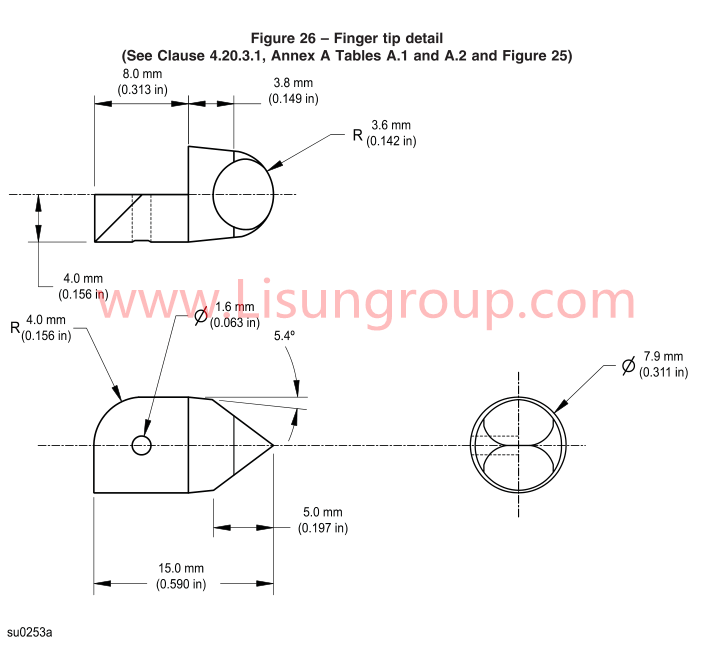

| Middle finger diameter-female-5th percentile | 0.79 cm (0.311 in) |

| Note: | All dimensions apply to the 13-18 month age bracket (male and female). |

| Probe material | Stainless steel |

Test Procedures:

1. Inspect the probe for damage (bent tip, cracked insulation, poor conductivity) and confirm rigidity.

2. Power on the equipment under test (EUT, e.g., industrial transformer) and set it to normal operating mode.

3. Hold the insulated handle, align the 12mm probe tip with EUT openings (e.g., vent slots, terminal panel gaps).

4. Apply a steady 50N thrust to the probe—advance until resistance from the enclosure or internal components stops insertion.

5. Check the connected live-part detection instrument for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if live parts are accessible.

Applications:

1. Testing vent slot gaps in industrial transformers (per UL 1017:2023 Figure 25) to block access to high-voltage windings.

2. Quality control for medical device power transformers (e.g., MRI machine power units) during manufacturing.

3. Post-production testing of industrial control enclosure gaps to meet North American electrical safety standards.

UL 1017 Figure 25 Accessibility Probe

UL 1017 Figure 26 Finger tip detail