Product No: SMT-TD15

IEC 60950 Figure 2c SM430E Test Probe is a specialized safety tool designed to verify the inaccessibility of hazardous live or mechanical parts in information technology (IT) equipment. It features a rigid stainless steel probe tip for consistent access simulation and an insulating nylon handle for safe, non-slip operation. Engineered to match the precise dimensions of UL’s specifications, it applies minimal force to mimic accidental contact—critical for ensuring IT devices meet global safety standards. Durable and easy to maneuver, it’s essential for manufacturers and labs conducting compliance tests to prevent electric shock.

Specifications:

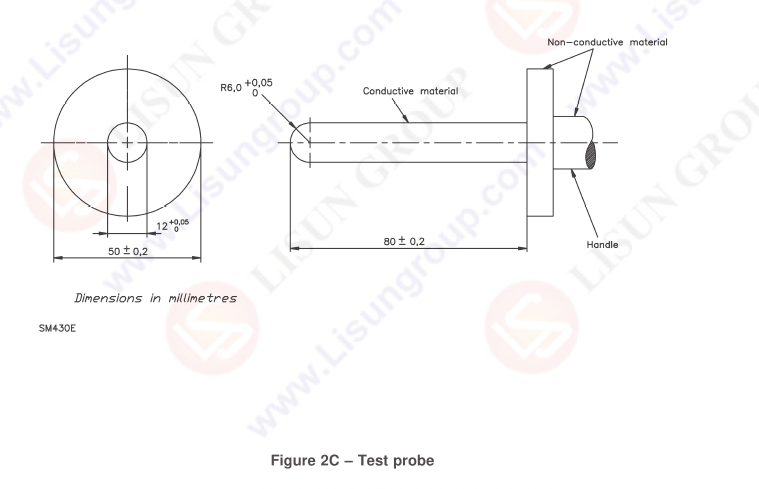

• Probe Type: IEC 60950 Figure 2c SM430E Test Probe

• Probe Material: Stainless steel (rigid, corrosion-resistant, maintains dimensional accuracy)

• Handle Material: Nylon (insulating, heat-resistant, non-slip for secure grip)

• Key Dimensions:

– Probe Tip Diameter: 1.0 mm ± 0.05 mm

– Effective Probe Length: 80 mm ± 0.2 mm

– Handle Length: 100 mm ± 0.5 mm

– Total Length: 180 mm ± 0.5 mm

• Applied Force: No appreciable force (mimics light, accidental contact with IT equipment)

• Core Function: Verifies inaccessibility of hazardous live/mechanical parts in IT and electrical business equipment

Test Procedures:

• Inspect the probe for damage (e.g., bent tip, cracked handle) to ensure testing accuracy.

• Power on the IT equipment and allow it to reach normal operating mode.

• Hold the nylon handle and align the stainless steel tip with equipment openings (e.g., vents, port gaps).

• Gently guide the probe toward internal hazardous parts (e.g., live circuits, moving components).

• Check if the probe touches any dangerous elements.

• Record whether the equipment meets safety requirements (pass/fail).

Applications:

• Safety testing of laptop power adapters (per UL 60950-1 Figure 2c / UL 62368-1).

• Compliance checks for server chassis to block access to internal live parts.

• Verification of desktop monitors and all-in-one PCs to prevent electric shock risks.

• Quality control for network switches and routers during manufacturing for global IT markets.

• Post-production safety audits of IT equipment power supplies (e.g., UPS systems) to meet UL/IEC standards.

Test Probe SM430E UL 60950-1 Figure 2C