Product No: SMT-PA140B

UL 921 Figure 3 PA140B Test Probe for Film-Coated Wires is a specialized safety tool designed to verify the insulation integrity of film-coated electrical wires – critical for detecting tiny cracks, pinholes, or damages in the coating that could cause (electric leakage). It features a conductive brass probe tip (for precise contact with the wire surface) and an insulating nylon handle (to protect testers from electric shock). Engineered to apply light, controlled pressure, it mimics real-world use scenarios while strictly aligning with UL 921 requirements. Durable and dimensionally stable, it’s essential for manufacturers and labs to ensure film-coated wires meet U.S. safety standards for scientific, industrial, and medical auxiliary equipment.

Specifications:

• Probe Type: UL 921 Figure 3 Test Probe (for film-coated wire insulation integrity testing)

• Probe Tip Material: Brass (highly conductive, ensures reliable contact with wire coatings; corrosion-resistant)

• Handle Material: Nylon (fully insulating, heat-resistant, non-slip for precise pressure control)

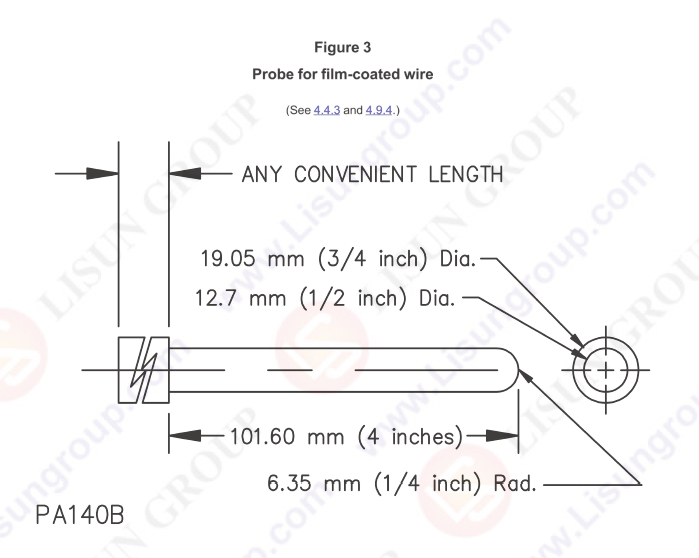

• Key Dimensions:

– Probe Tip Diameter: 1.5 mm ± 0.05 mm (ideal for small-diameter film-coated wires)

– Effective Probe Length: 25 mm ± 0.2 mm

– Handle Length: 100 mm ± 0.5 mm

– Total Length: 125 mm ± 0.5 mm

• Electrical Conductivity Probe: tip resistance ≤ 0.1 Ω (ensures accurate leakage detection)

• Applied Force: No appreciable force (light contact only, to avoid damaging intact film coatings)

• Core Function: Detects insulation damages (cracks, pinholes) in film-coated wires per UL 921 standards

Test Procedures:

• Inspect the probe (no bent tip, cracked handle, or poor conductivity) and connect it to a leakage detection instrument.

• Prepare the film-coated wire—ensure it’s clean, dry, and placed on a non-conductive surface.

• Hold the insulating handle and align the brass probe tip with the wire’s film coating.

• Apply light, even contact (no force) to glide the probe along the wire’s length.

• Check the detection instrument for signals (indicating coating damage and leakage).

• Record damaged areas and whether the wire meets safety requirements (pass/fail).

Applications:

• Safety testing of film-coated wires in scientific lab equipment (e.g., analyzers, electrophoresis machines).

• Compliance checks for film-coated wires in industrial control panels.

• Verification of film-insulated wires in medical auxiliary devices (e.g., clinical chemistry equipment) for U.S. markets.

• Quality control for small-diameter film-coated wires during manufacturing (e.g., for IoT sensor wiring).

• Post-production audits of film-coated wires in precision electrical instruments (e.g., measuring tools) to ensure insulation integrity.

Test Probe of UL 921 Figure 3 for Film-coated Wire with Standard