Product No: SMT-PA140C

UL 1017 Figure 3 Straight Probe is a specialized safety tool for testing vacuum cleaners, blower cleaners, and household floor finishing machines. It features a precision-engineered straight design with defined dimensions—critical for simulating accidental access to hazardous parts like rotating brushes or live components. Made from durable stainless steel to withstand repeated testing, it’s easy to handle and aligns strictly with UL’s safety standards. The probe ensures reliable verification that dangerous parts remain inaccessible, making it essential for manufacturers and labs to meet UL 1017 compliance and prevent user injuries.

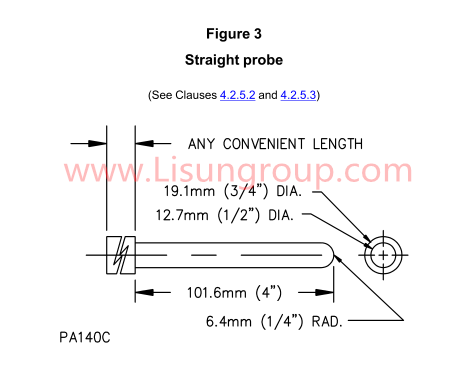

Specifications:

• Probe Type: Straight Probe (UL 1017 Figure 3 compliant for cleaning/finishing machine testing)

• Material: Durable stainless steel (resists bending, maintains dimensional accuracy)

• Total Length: 101.6 mm (4 inches)

• Head Diameter: 12.7 mm (1/2 inch)

• Head Radius: 6.4 mm (1/4 inch) (smooth, to avoid damaging appliance enclosures)

• Tail Diameter: 19.1 mm (3/4 inch) (for stable handling during testing)

• Core Function: Verifies inaccessibility of hazardous mechanical/live parts in vacuum cleaners, blower cleaners, and floor finishing machines

• Applied Force: No appreciable force (mimics light, accidental user contact)

Test Procedures:

• Inspect the probe for damage (e.g., bent body, dented head) that could affect accuracy.

• Power on the appliance (vacuum cleaner, floor finisher) and let it reach normal operating mode.

• Hold the probe by its tail and align the head with potential access points (e.g., brush guards, vents).

• Gently guide the probe toward internal hazardous parts.

• Check if the probe touches any dangerous components.

• Record whether the appliance meets UL 1017 safety requirements (pass/fail).

Applications:

• Safety testing of household vacuum cleaners.

• Compliance checks for blower cleaners to block access to rotating impellers.

• Verification of electric floor finishing machines (e.g., buffer polishers) for mechanical hazard protection.

• Quality control for commercial vacuum cleaners (e.g., office or hotel models) during manufacturing.

• Post-production safety audits of household floor care appliances to ensure UL 1017 compliance.

Straight Probe of UL 1017 Figure 3