Product No: SMT-PA120

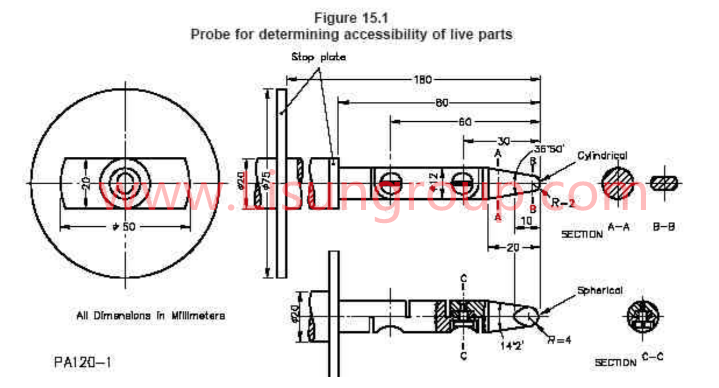

The UL 1703 Figure 15.1 Test Probe (PA120-1) is a precision tool designed to check the accessibility of live parts in flat-plate photovoltaic (PV) modules and panels—critical for preventing electric shock in solar energy systems. It features a 12mm knurled stainless steel finger (80mm long) that mimics human contact, paired with a 50mm diameter baffle plate to stop over-insertion. Its jointed design allows rotation and angling during use, ensuring it reaches gaps in PV components (e.g., Junction Box,panel seams) with minimal force (to avoid damaging materials). Compliant with UL, CSA, and IEC standards, it’s essential for PV manufacturers to validate safety and meet global solar equipment regulations.

Specifications:

Tool Type: UL 1703 Figure 15.1 Test Probe (for live part accessibility testing in flat-plate PV modules/panels)

Test Finger Material: Knurled stainless steel (resistance ≤ 0.1Ω; corrosion-resistant; durable for repeated use on PV components)

Handle/Baffle Material: Insulated plastic (handle resistance ≥ 100MΩ; heat-resistant up to 120°C; baffle plate for over-insertion protection)

Key Dimensions:

– Knurled Finger Diameter: 12mm ± 0.1mm

– Knurled Finger Length: 80mm ± 0.2mm

– Baffle Plate Diameter: 50mm ± 0.2mm

– Baffle Plate Length: 100mm ± 0.2mm

– Baffle Plate Thickness: 20mm ± 0.1mm

– Total Length (Probe + Handle): 300mm ± 0.5mm

Joint Characteristics: Jointed design; 360° rotation and 90° ± 10° angling (to navigate PV component gaps); no deformation under minimal test force

Applied Force: Minimal force (≤5N) – enough to determine accessibility without damaging PV module materials (per UL 1703 requirements)

Core Function: Detects accessible live parts in PV modules/panels; mimics human contact via knurled finger; ensures compliance with solar safety standards

Test Procedures:

1. Inspect the probe for bent fingers, loose joints, or cracked insulation; confirm conductivity with a test tool.

2. Place the PV module/panel under test (EUT) on a flat, non-conductive surface; power it to normal operating mode.

3. Hold the insulated handle, insert the 12mm knurled finger into EUT gaps (e.g., Junction Box, slots, panel edges).

4. Rotate and angle the probe before, during, and after insertion to explore all possible positions.

5. Apply minimal force—check the connected live-part detector for signals (indicating contact with live parts).

6. Record results: Pass if no contact; Fail if the probe reaches live components.

Applications:

1. Testing (junction box) gaps in residential PV panels (per UL 1703:2023 Figure 15.1) to block access to live wiring.

2. Verifying edge seams in commercial flat-plate PV modules (compliant with CSA C22.2 No. 1703:2023) to prevent electric shock.

3. Safety checks for PV inverter input terminals (per IEC 61032:2017) to avoid live-part exposure.

4. Quality control for solar panel frames during manufacturing, ensuring UL 1703 compliance for live-part protection.

5. Post-installation testing of utility-scale PV array components to meet global solar energy system safety rules.

Test Probe for Determining Accessibility of Live Parts PA120-1 with UL 1703 Figure 15.1