Product No: SMT-SA1788A

This dual-compliant probe (aligned with IEC standards and UL 1017 Figure 4) is a critical safety tool for transformers, power supplies, and industrial reactors—used globally, especially in North American and international markets. It tests if hazardous live parts (e.g., high-voltage windings, terminal blocks) are accessible through equipment gaps (vents, panel seams, terminal openings). Featuring a rigid conductive stainless steel tip (matched to UL 1017 Figure 4’s dimensions) and a heat-resistant insulated handle.

Specifications:

Tool Type: IEC/UL 1017 Figure 4 Dual-Compliant Safety Probe (for transformers/power supplies hazardous part testing)

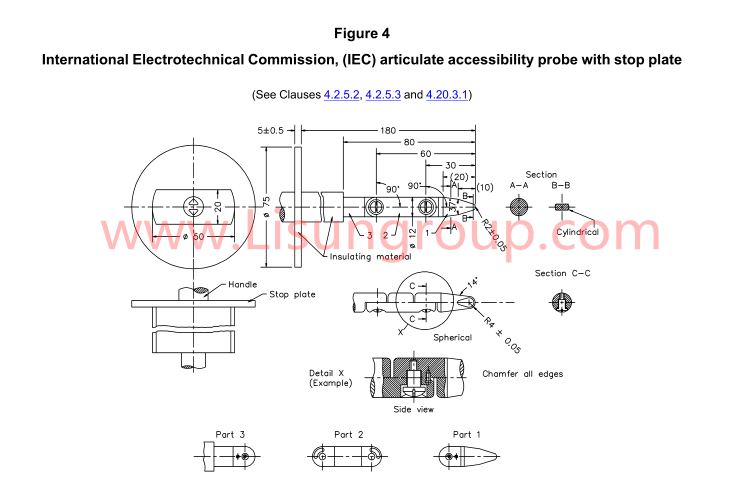

Key Dimensions:

– Knurled Finger Diameter: 12 mm

– Knurled Finger Length: 80 mm

– Baffle Plate Diameter: 50 mm

– Baffle Plate Length: 100 mm

– Baffle thickness: 20 mm

Core Function: Detects accessible hazardous live parts in transformers/power supplies; ensures compliance with both IEC standards and UL 1017 Figure 4

Test Procedures:

1. Inspect the probe for damage (bent tip, cracked insulation, poor conductivity) and confirm rigidity.

2. Power on the equipment under test (EUT, e.g., commercial transformer) and set it to normal operating mode.

3. Hold the insulated handle, align the 8mm probe tip with EUT gaps (vents, terminal panel seams).

4. Apply a steady 30N thrust to the probe—advance until resistance stops insertion.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if live parts are accessible.

Applications:

1. Testing vent gaps in industrial transformers (per UL 1017:2023 Figure 4) to block high-voltage winding access.

2. Quality control for medical device transformers (e.g., ultrasound machine power units) during manufacturing.

3. Post-production testing of industrial reactors’ panel seams to meet both North American and international safety rules.

UL 1017 Figure 4 International Electrotechnical Commission, (IEC) Articulate Accessibility Probe with Stop Plate.