Product No: SMT-02T30

The IEC 60601 Figure 6 Standard Articulated Test Probe (30N Thrust) is a precision safety tool designed to simulate human finger movement for testing access to hazardous live parts, hot components, or moving parts in medical, household, and IT equipment. It features articulated joints that bend 90°±10° in one direction (mimicking natural finger motion), a chrome-plated stainless steel probe for durability, and a polyamide handle for insulated, comfortable grip. Applying a controlled 30N thrust to mimic real-world accidental contact, it complies with IEC, CSA, and UL standards—critical for manufacturers to validate safety and prevent electric shock or injury.

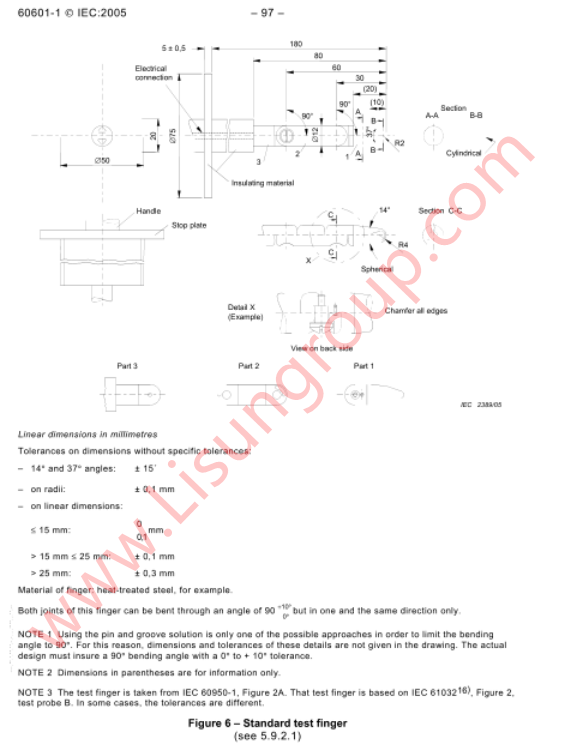

Specifications:

Tool Type: Standard Articulated Test Probe (IEC 60601 Figure 6; for hazardous part accessibility testing in medical/household/IT equipment)

Probe Material: Stainless steel (heat-treated for rigidity; chrome-plated finish for corrosion resistance; smooth surface to avoid equipment damage)

Handle Material: Polyamide (insulated; resistance ≥ 100MΩ; heat-resistant up to 110°C; ergonomic non-slip grip)

Joint Characteristics: 2 articulated joints; bends 90°±10° in one direction only; no jamming under 30N thrust

Applied Thrust: 30N ± 2N (simulates accidental human contact; aligns with IEC 60601 safety requirements)

Key Dimensions & Tolerances:

– Angles (14°, 37°): ±15′

– Radii: ±0.1mm

– Linear Dimensions: ≤15mm (0mm tolerance); 15–25mm (±0.1mm); >25mm (±0.3mm)

– Total Length: Aligned with IEC 60601 Figure 6 (typical 300mm ± 0.3mm)

Core Function: Simulates human finger to test hazardous part accessibility; applies 30N thrust for real-world validation; ensures compliance with global safety standards

Test Procedures:

1. Inspect the probe for loose joints, bent sections, cracked handles, or worn plating; confirm joint bending range (90°±10°).

2. Power on the equipment under test (EUT, e.g., patient monitor) and set it to normal operating mode.

3. Hold the polyamide handle, use the articulated joints to guide the probe into EUT gaps (control panels, chassis seams).

4. Apply steady 30N thrust—stop if resistance blocks insertion or the probe contacts the EUT’s outer surface.

5. Check the connected live-part detector for signals (indicating contact with hazardous parts).

6. Record results: Pass if no contact; Fail if the probe reaches dangerous components.

Applications:

1. Testing access to live circuits in patient monitors (per IEC 60601-1:2020 Figure 6) to prevent electric shock in hospitals.

2. Verifying hazard accessibility in household ovens (compliant with IEC 60335-1:2023) to block contact with hot heating elements.

3. Safety checks for router chassis seams (per IEC 61032:2017 Figure 2) to avoid exposure to internal wiring.

4. Quality control for infusion pumps during manufacturing, ensuring IEC 60601 compliance for medical safety.

5. Post-production testing of electric coffee makers to meet global household appliance hazard protection standards.

IEC 60601 Figure 6