Product No: SMT-S113

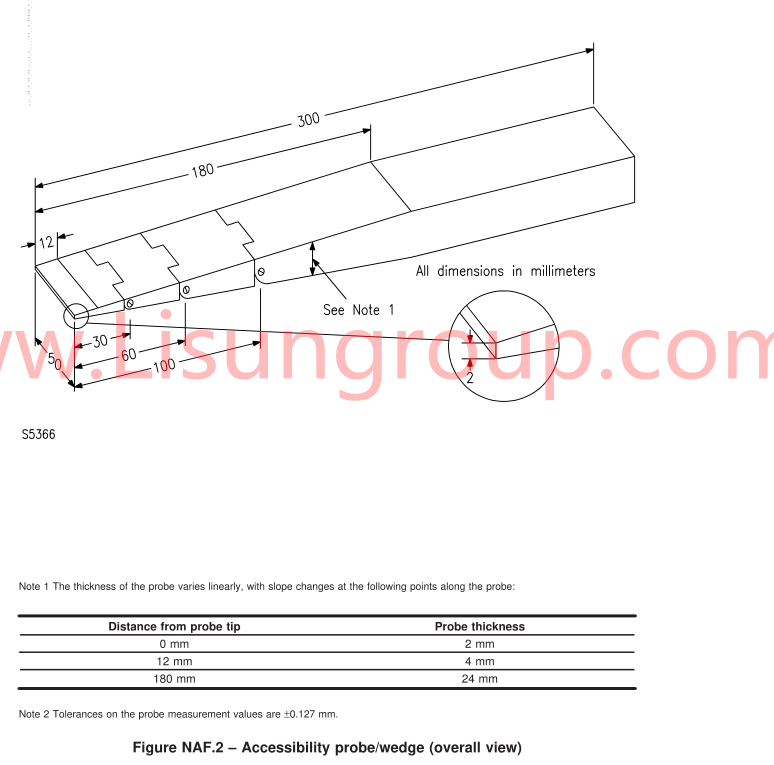

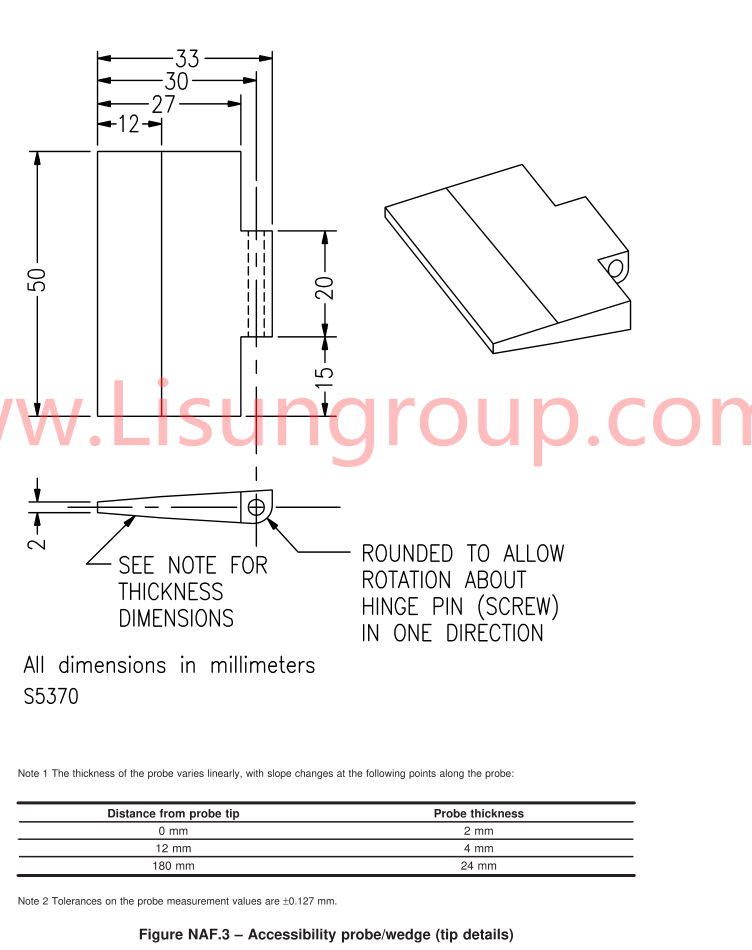

This Accessibility Wedge Probe Set (S5366/S5370) is tailored for testing IT equipment, compliant with UL 60950-1 Figures NAF-2/NAF-3. It features precision-machined stainless steel wedge tips—S5366 mimics thin, narrow wedges, while S5370 simulates wider ones—to replicate accidental insertion into equipment gaps (e.g., port slots, vent edges). Paired with insulating nylon handles for safe grip, both apply light force to verify if hazardous live parts or moving components remain inaccessible. Durable and dimensionally accurate, it’s essential for manufacturers to meet global IT equipment safety compliance.

Specifications:

| Parameter | S5366 (UL 60950-1 Figure NAF-2) | S5370 (UL 60950-1 Figure NAF-3) |

| Probe Type | Narrow Wedge Accessibility Probe | Wide Wedge Accessibility Probe |

| Wedge Material | Stainless steel (rigid, corrosion-resistant) | Stainless steel (rigid, corrosion-resistant) |

| Handle Material | Nylon (insulating, non-slip, heat-resistant) | Nylon (insulating, non-slip, heat-resistant) |

| Core Function | Tests narrow gaps in IT equipment for hazardous part access | Tests wider gaps in IT equipment for hazardous part access |

Test Procedures:

1. Inspect both probes for damage (bent tips, cracked handles) to ensure accuracy.

2. Power on the IT equipment and let it reach normal operating mode.

3. Select S5366 (narrow gaps) or S5370 (wider gaps) based on the test area.

4. Hold the nylon handle and align the wedge tip with the target equipment opening.

5. Gently insert the wedge toward internal hazardous parts—avoid force.

6. Check if the wedge touches live components/moving parts, then record pass/fail.

Applications:

1. Safety testing of laptop port slots (USB-C, HDMI) using S5366 (UL 60950-1).

2. Compliance checks for router vent gaps with S5370 to block access to internal wiring.

3. Verification of server chassis edges (narrow seams) using S5366 per UL 60950-1.

4. Quality control for desktop monitor bezel gaps (wider slots) with S5370 during manufacturing.

5. Post-production audits of office printers (paper tray gaps) to meet UL 60950-1 standards.

Accessibility Probe/Wedge (S5366 + S5370) UL 60950-1 Figure NAF.2 & NAF.3

Accessibility Probe/Wedge (S5366 + S5370) UL 60950-1 Figure NAF.2 & NAF.3