Product No: GNGPL-3137

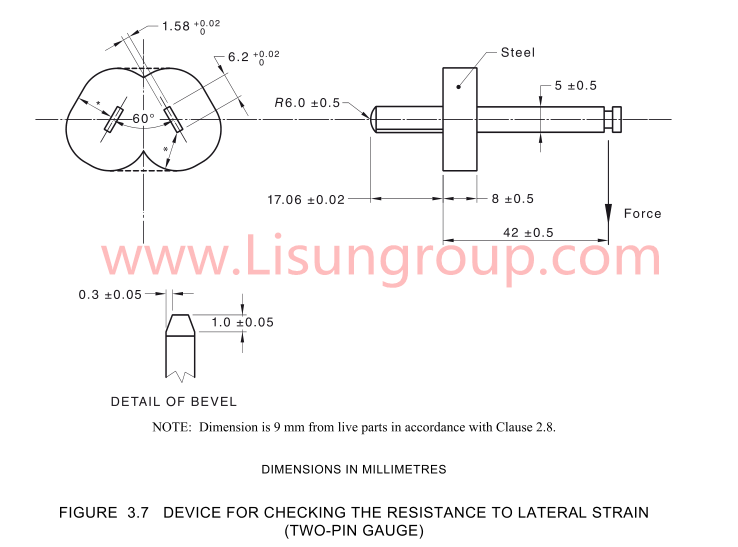

Device for Checking The Resistance to Lateral Strain (Two-Pin Gauge) According to AS/NZS 3112 Figure 3.7 is specialized in evaluating the resistance to lateral strain of plugs and sockets that comply with the Australian/New Zealand Standard AS/NZS 3112. Precisely crafted to align with the technical specifications outlined in AS/NZS 3112 Figure 3.7, it features high-precision dimensional control, durable steel construction, and excellent structural stability—ensuring accurate and repeatable test results for verifying product compliance and mechanical reliability.

Specifications:

• Complies with AS/NZS 3112 “Approval and test specification – Plugs and socket – outlets” Figure 3.7

• Material: High-quality steel with wear-resistant properties

• Material hardness: Exceeds 50HRC for long-term use without deformation

• Thermal expansion coefficient: Low, maintaining dimensional stability across different test environments

• Key dimensions and tolerances: Conform to standard requirements (including 1.58±0.02mm, 6.2±0.02mm, 19.94±0.02mm, 42±0.5mm, R6.0±0.5mm, R20mm, 60° bevel angle, 0.3±0.05mm, 5±0.5mm)

• Surface finish: Smooth with specified roughness to avoid damaging test samples

• Pin configuration: Two pins with uniform width, thickness, and spacing as per standard

Test Procedures:

• Prepare the AS/NZS 3112-compliant plug or socket sample, ensuring it is free from scratches, cracks, deformation, or any defects that may affect test validity.

• Inspect the two-pin gauge to confirm it is clean, free of debris or wear, and its critical dimensions are within the specified tolerance range.

• Secure the sample in a stable test fixture to prevent displacement during the application of lateral force.

• Align the two pins of the gauge with the corresponding contact positions of the sample strictly in accordance with AS/NZS 3112 Figure 3.7 guidelines.

• Apply the standard-specified lateral force to the gauge in a steady, uniform manner, avoiding sudden or uneven pressure.

• Maintain the applied lateral force for the duration required by the AS/NZS 3112 standard to assess the sample’s resistance capability.

• After the specified force duration, gently remove the gauge and visually inspect the sample for structural damage, loosening, or permanent deformation.

• Document all test parameters (including applied force, duration, and sample condition) and determine if the sample meets AS/NZS 3112 compliance requirements based on the observations.

Applications:

• Lateral strain resistance testing of two-pin plugs and sockets manufactured to AS/NZS 3112 standards

• Quality control and compliance inspection in electrical product manufacturing facilities

• Mechanical performance evaluation during R&D of plug and socket products for Australian/New Zealand markets

• Routine quality audits and batch inspection of electrical connectors

• Compliance certification testing for manufacturers seeking market access in Australia and New Zealand

• Quality verification of plug and socket accessories used in household, commercial, or industrial electrical systems

Device for Checking The Resistance to Lateral Strain (Two-Pin Gauge) of AS/NZS 3112 Figure 3.7