Product No: GNGPL-3634

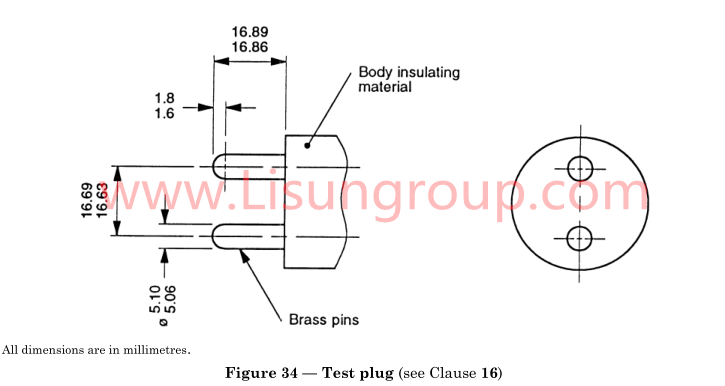

Test Plug According to BS 1363-3 Figure 34 is a precision-engineered tool designed to verify the structural and dimensional compliance of plugs, sockets, and adaptors with BS 1363 standards, as detailed in Figure 34 of BS 1363-3 (“13 A plugs, socket-outlets, adaptors and connection units – Adaptors. Specification”). It adheres strictly to the standard’s requirements for dimensions, tolerances, material properties, hardness, and surface roughness, featuring brass pins and an insulating body. With a material hardness exceeding 50HRC and a low thermal expansion coefficient, the test plug ensures stable and reliable performance, delivering accurate results for validating the conformity of relevant electrical components.

Specifications

• Compliance standard: BS 1363-3 (“13 A plugs, socket-outlets, adaptors and connection units – Adaptors. Specification”) Figure 34

• Pin material: Brass

• Body material: Insulating material

• Material hardness: Over 50HRC

• Material thermal expansion coefficient: Low

• All linear dimensions: Specified in millimetres

• Key attributes (dimensions, tolerances, surface roughness): Fully compliant with BS 1363 standard requirements

• Dimensional stability: Stable and reliable due to low thermal expansion coefficient

Test Procedures

• Prepare the socket, plug, or adaptor sample for testing, ensuring it is free from damage, dirt, or debris that may impact test accuracy.

• Inspect the test plug to confirm its brass pins are intact, the insulating body is free from cracks or wear, and all dimensions meet BS 1363-3 Figure 34 requirements.

• Align the test plug with the sample (socket, plug, or adaptor) in accordance with the guidelines outlined in Clause 16 of the BS 1363-3 standard.

• Insert the test plug into the sample smoothly, checking for proper fit without excessive resistance or looseness.

• Verify that the sample’s structural features (e.g., pin receiving slots, contact points) align with the test plug’s dimensions and tolerances.

• Conduct a visual and tactile inspection to ensure the sample maintains structural integrity and compliance during and after insertion.

• Record the test results comprehensively, indicating whether the sample meets BS 1363 standards based on the test plug’s inspection outcomes.

Applications

• Dimensional and structural compliance testing of plugs, sockets, and adaptors against BS 1363-3 Figure 34 requirements.

• Quality control processes in the electronics industry for plug, socket, and adaptor components.

• Compliance verification in the electrical appliance industry to ensure the safety and compatibility of 13 A electrical connection assemblies.

• R&D and production quality assurance for manufacturers of 13 A plugs, socket-outlets, adaptors, and related connection units.

• Conformity assessment for electrical component manufacturers requiring adherence to BS 1363-3 standards.

• Routine inspection of electrical connection products in industries relying on standardized 13 A plug-and-socket systems.

Test Plug According to BS 1363-3 Figure 34