Product No: GNGPL-3630

This Test Plug for Temperature Rise Designed According to BS1363-2 Figure 30 is a precision-engineered testing tool developed in strict compliance with BS 1363-2 Figure 30, specifically designed to evaluate the thermal performance of 13 A switched and unswitched socket-outlets. It integrates key features such as brass pin/clamp assemblies, a wire-wound ceramic-coated resistor, and thermal contact compound to simulate real-world operating conditions accurately. The plug’s pin projection size and disposition adhere to BS 1363-1:2023 Figure 4a, ensuring seamless compatibility with test samples. With a robust synthetic resin bonded paper (SRBP) body and securely soldered conductors, it delivers consistent heat generation and reliable temperature measurement, making it an indispensable instrument for compliance testing, quality control, and R&D in the electrical accessory industry.

Specifications

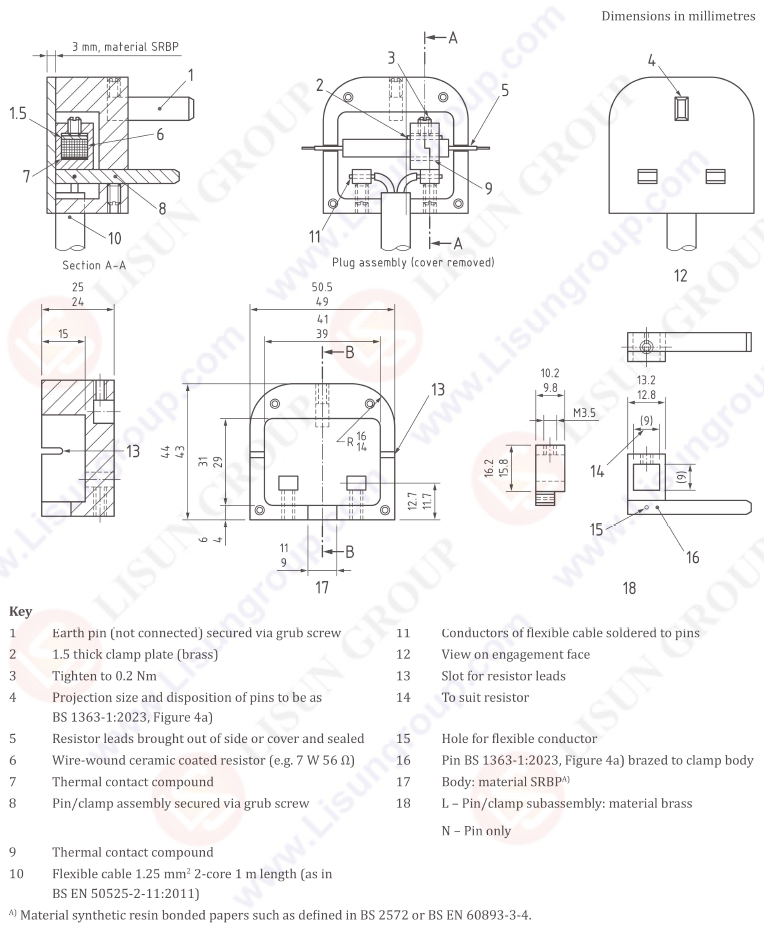

• Test standard compliance: BS 1363-2 Figure 30 (for 13 A switched and unswitched socket-outlets); pin specifications aligned with BS 1363-1:2023 Figure 4a

• Core components: Earth pin (non-connected, secured by grub screw), brass pin/clamp assembly, 1.5 mm thick brass clamp plate, wire-wound ceramic-coated resistor (e.g., 7 W 56 Ω), thermal contact compound, flexible cable

• Body material: Synthetic resin bonded paper (SRBP), as defined in BS 2572 or BS EN 60893-3-4

• Cable specifications: 1.25 mm² 2-core flexible cable, 1m length, compliant with BS EN 50525-2-11:2011

• Fastening details: Pin/clamp subassembly secured via grub screw; clamp plate tightened to 0.2 Nm torque

• Structural features: Slot for resistor leads; hole for flexible conductor; resistor leads sealed when brought out of side or cover

• Pin material: Brass (pin/clamp subassembly); pin-only components meet BS 1363-1:2023 dimensional requirements

• Compatibility: Tailored for temperature rise testing of 13 A switched and unswitched socket-outlets

Test Procedures

• Inspect the test plug for structural integrity: verify the SRBP body is free of cracks, pins are securely fastened, soldered connections between conductors and pins are intact, and thermal contact compound is properly applied.

• Confirm the resistor (e.g., 7 W 56 Ω) is functional and securely seated, with leads properly routed through the designated slot and sealed.

• Prepare the 13 A switched or unswitched socket-outlet to be tested, ensuring it is free of debris, damage, or pre-existing thermal degradation.

• Insert the test plug firmly into the socket-outlet, ensuring full engagement of pins (aligned with BS 1363-1:2023 Figure 4a) and proper thermal contact with the socket’s internal components.

• Connect the flexible cable of the test plug to a compatible power supply, ensuring the electrical connection is secure and meets safety standards.

• Position temperature sensors (e.g., thermocouples) at specified test points on the socket-outlet, following BS 1363-2 protocols for accurate thermal measurement.

• Activate the power supply to initiate the temperature rise test, maintaining the specified operating conditions for the duration required by the standard.

• Continuously monitor and record temperature data at regular intervals, ensuring the test plug operates stably without overheating or electrical issues.

• Upon completion of the test cycle, disconnect the power supply and allow the test plug and socket-outlet to cool down safely.

Remove the test plug, inspect both the plug and socket-outlet for signs of deformation or damage, and compare the recorded temperature data against BS 1363-2 requirements to assess compliance.

Applications

• Temperature rise testing of 13 A switched socket-outlets to validate compliance with BS 1363-2 thermal safety standards.

• Thermal performance evaluation of 13 A unswitched socket-outlets under simulated operating conditions.

• Quality control inspections in manufacturing facilities producing socket-outlets for markets adhering to BS 1363-2 specifications.

• Certification testing conducted by third-party laboratories and regulatory bodies to confirm product conformity with thermal safety requirements.

• R&D testing for optimizing the design, material selection, and thermal management of 13 A socket-outlets.

• Pre-shipment quality verification for exporters, ensuring products meet the temperature rise standards of target markets.

• Routine thermal performance audits for electrical accessory brands to maintain consistent product safety and reliability.

• Training and calibration of testing personnel in BS 1363-2 compliant temperature rise test procedures.

Test plug of BS1363-2 Figure 30