Product No: GNGPL-SU3639

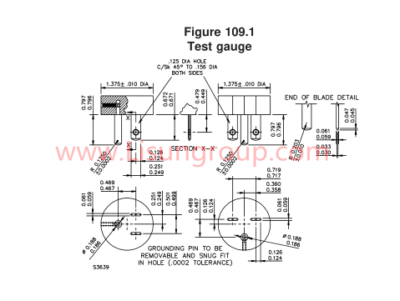

This Test Gauge According to UL 498 Figure 109.1 is precision-engineered to validate the structural and dimensional compliance of plugs and sockets with UL 498:2012 standards, specifically adhering to the requirements of Figure 109.1. It features strict conformity to standard specifications for dimensions, tolerances, material properties, and surface finish, with high hardness and minimal thermal expansion ensuring stable, reliable performance in electrical component inspection.

Specifications:

• Applicable standard: UL 498 Figure 109.1

• Key diameters: 0.156 in, 0.125 in

• Flat blade thickness: 0.124 in

• Critical dimensions: 0.061 in, 0.25 in, 0.240 in, 0.360 in, 0.719 in, 0.717 in, 0.186 in

• Angle: 45° (both sides)

• Grounding pin: Removable with snug fit, installed in a hole with ±0.0002 in tolerance

• Material hardness: ≥50HRC

• Material thermal expansion coefficient: Small, ensuring dimensional stability

• Dimensional tolerances: Compliant with UL 498:2012 requirements

• Surface roughness: Meets UL 498 specified standards

Test Procedures:

• Inspect the test gauge for cleanliness, no visible damage, or dimensional irregularities before use; confirm the removable grounding pin is snugly fitted.

• Secure the plug or socket under test in a stable fixture to prevent displacement during inspection.

• Align the gauge with the designated testing position of the product as outlined in UL 498:2012 Figure 109.1.

• Conduct structural and dimensional inspection by guiding the gauge through the relevant features (slots, holes) of the test sample.

• Verify if the product’s structure and key dimensions align with the tolerances and specifications of UL 498:2012.

• Document the test data and confirm whether the product meets the standard’s compliance criteria.

Applications:

• Structural and dimensional inspection of plugs and sockets to ensure conformity with UL 498:2012 standards.

• Quality control processes in the electronics and electrical appliance manufacturing industries.

• Conformity testing for plug and socket products on production lines and in workshops.

• R&D testing for optimizing the design of plug and socket components.

• Compliance verification in third-party testing laboratories and certification institutions.

Test Gauge According to UL 498 Figure 109.1