Product No: GNGPL-SB1888

This UL 498 Figure 74.2 SB1888 Typical Test Apparatus is specifically engineered to fully comply with the requirements outlined in Figure 74.2 of the UL 498 standard (“Attachment Plugs and Receptacles”). It is a dedicated testing tool designed to evaluate the blade retention performance of attachment plugs and receptacles— a critical safety attribute that ensures electrical blades remain securely in place during use, preventing accidental disconnection or exposure to live components. The apparatus integrates key functional components to simulate real-world usage conditions, enabling accurate and repeatable testing. It serves as an essential instrument for manufacturers, testing laboratories, and quality assurance teams to verify that plugs and receptacles meet the strict safety and performance standards set by UL 498.

Specifications:

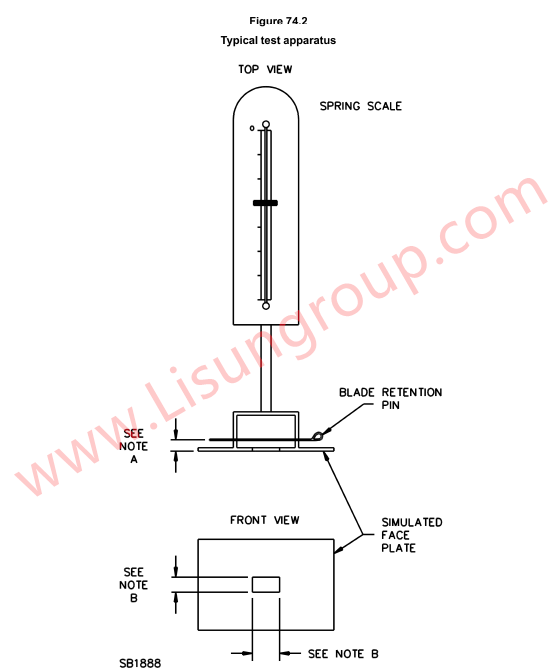

• Fully complies with UL 498 standard, specifically aligning with the technical requirements of Figure 74.2 (“Typical test apparatus”)

• Features a spring scale component, which is used to measure the force required for blade retention testing, ensuring accurate force quantification

• Includes a blade retention pin, a core part that interacts with the sample’s blades to assess retention strength

• Incorporates a simulated face plate, designed to replicate the actual installation environment of plugs and receptacles, ensuring test conditions mirror real-world usage

• Provides both top view and front view structural configurations, meeting the dimensional and assembly specifications detailed in UL 498 Figure 74.2

• Engineered exclusively for blade retention performance testing of attachment plugs and receptacles

Test Procedures:

• Prepare the attachment plug or receptacle sample for testing, ensuring it is free from visible damage, assembled correctly according to product specifications, and meets the pre-test conditions defined by UL 498.

• Set up the typical test apparatus on a stable, level testing platform. Ensure all components (including the spring scale, blade retention pin, and simulated face plate) are properly installed, calibrated, and in good working condition.

• Mount the sample onto the simulated face plate of the apparatus, aligning the sample’s blades with the blade retention pin to ensure proper engagement, as specified in the structural guidelines of UL 498 Figure 74.2.

• Activate the test by using the spring scale to apply a gradual, controlled force to the blade retention pin (or the sample’s blades, depending on test requirements) in the direction specified by UL 498, to evaluate the blade’s resistance to disconnection.

• Monitor and record key test data throughout the process, including the maximum force applied, the stability of the blade’s position, and whether the blade remains securely retained without exceeding the allowable displacement limits set by UL 498.

• After completing the test, dismount the sample from the apparatus, inspect both the sample and the apparatus components for any signs of wear, deformation, or damage, and document the test results to confirm whether the sample meets UL 498’s blade retention performance requirements.

Applications:

• Quality control testing in the manufacturing process of attachment plugs and receptacles, used to verify the blade retention performance of finished products before shipment, ensuring each unit meets UL 498 safety standards and avoids potential hazards caused by loose blades.

• UL certification compliance testing for electrical product manufacturers, as the apparatus enables accurate validation of blade retention— a mandatory requirement for obtaining UL 498 certification for plugs and receptacles, facilitating market access.

• R&D testing in the development of new plug and receptacle models, helping engineers optimize the design of blade retention structures, assess the performance of different materials or component configurations, and ensure new products meet safety standards from the early development stage.

• Third-party testing laboratories conducting impartial safety and compliance assessments of electrical products, providing a standardized testing tool to objectively evaluate the blade retention performance of client-submitted plugs and receptacles.

• Incoming quality inspection for distributors or importers of attachment plugs and receptacles, used to spot-check batches of purchased products to confirm their blade retention meets UL 498 requirements, ensuring consistent product quality and safety across inventory.

UL 498 Figure 74.2 SB1888 Typical Test Apparatus