Product No: GNGPL-57C20

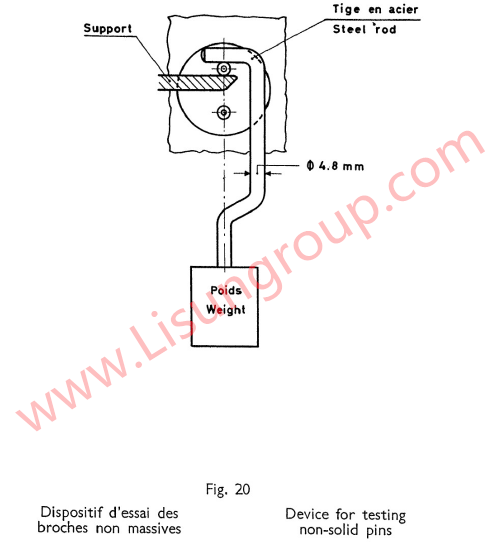

This CEE7 Fig. 20 Gauges C20 Device for Non-solid Pins is precision-engineered in strict compliance with the specifications outlined in IECEE CEE-7 Figure 20, a key standard for domestic and similar-purpose plugs and socket-outlets. It is exclusively designed to test the structural integrity and durability of non-solid pins in plugs, verifying their ability to resist deformation or damage under specified mechanical stress. By simulating real-world forces on non-solid pins, this device ensures that plugs meet CEE 7’s rigorous safety and performance requirements, preventing hazards from pin failure during use or insertion.

Specifications:

• Fully conforms to IECEE CEE-7 standard requirements, aligning with Figure 20 specifications for non-solid pin testing

• Core component: Steel rod (Tige en acier) with a diameter of 4.8 mm

• Integrated weight (Poids) for applying standardized mechanical stress during testing

• Manufactured from high-strength steel and durable materials to maintain dimensional stability and test accuracy

• Engineered to target non-solid pin structures without damaging surrounding plug components

• Calibrated for consistent force application to ensure repeatable test results

• Compatible with CEE 7-compliant plugs featuring non-solid pins for domestic and similar applications

Test Procedures:

• Inspect the test device for damage, wear, or dimensional deviations, confirming the steel rod’s diameter and weight comply with CEE 7 Figure 20 specifications.

• Prepare the test sample (plug with non-solid pins) and ensure it is clean, free from cracks, or pre-existing damage to the pins.

• Secure the plug firmly in a stable fixture, positioning the non-solid pin to be tested in a vertical or specified orientation per CEE 7 guidelines.

• Align the device’s steel rod with the center of the non-solid pin, ensuring the rod makes direct, perpendicular contact with the pin’s surface.

• Apply the integrated weight to the steel rod, exerting the standardized force specified in CEE 7 for non-solid pin testing.

• Maintain the force for the required duration outlined in the standard, observing the pin for any deformation, bending, or structural failure.

• After the test period, remove the weight and steel rod, then inspect the pin closely for signs of permanent damage or reduced functionality.

• Verify if the non-solid pin retains its original shape and structural integrity, meeting the pass criteria defined in IECEE CEE-7.

• Document test results, including observations of pin performance and whether the sample complies with the standard, and reset the device for subsequent tests.

Applications:

• Quality control testing of CEE 7-compliant plugs with non-solid pins in manufacturing facilities to verify structural integrity.

• Compliance assessment by certification bodies and third-party testing laboratories for IECEE CEE-7 certification of electrical products.

• R&D testing for the design optimization of non-solid pin structures, enhancing durability and resistance to mechanical stress.

• Routine inspection of production lines producing domestic and similar plugs with non-solid pins for regions requiring CEE 7 compliance.

• Performance verification of non-solid pin components supplied by third-party vendors to meet CEE 7 specifications.

• Post-production quality audits to confirm the reliability of non-solid pins before market release, preventing pin failure-related hazards.

• Quality assurance for manufacturers exporting plugs with non-solid pins to CEE 7-adopting markets, ensuring compliance with regional safety standards.

CEE7 Fig. 20 Gauges C20 Device for non-solid Pins