Product No: GNGPL-235C13A

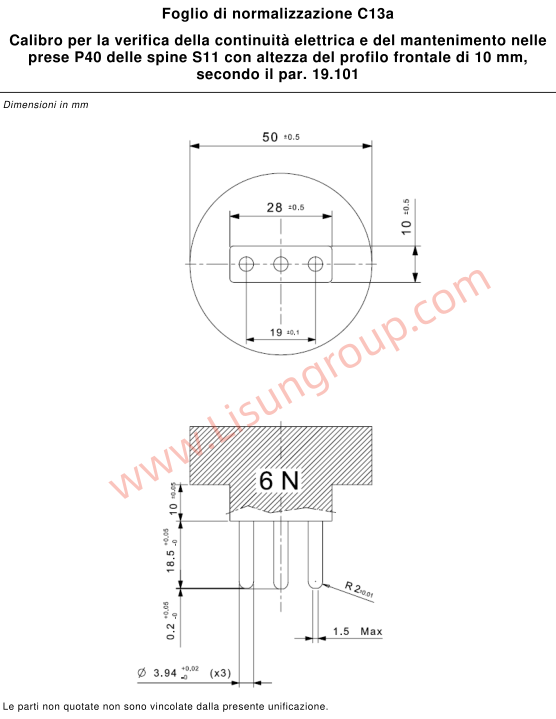

CEI 23-50 V4 Figure C13a Gauge Engineered to comply with the requirements of par. 19.101, this gauge is specifically designed for verifying the electrical continuity and retention of particular plugs in P40 sockets. It is customized for plugs with a 10 mm front profile height, featuring precise dimensional tolerances and robust construction to deliver consistent and accurate testing results that align with relevant industry standards.

Specifications:

• Overall dimension: 50 ±0.5 mm

• Dimension: 28 ±0.5 mm

• Dimension: 10 mm

• Dimension: 19 ±0.1 mm

• Dimension: 18 ±0.5 mm

• Radius: R 2 ±0.01 mm

• Maximum dimension: 1.5 mm

• Dimension: 0.2 mm

• Diameter: ø3.94 ±0.02 mm

• Feature: 3 sets of ø3.94 ±0.02 mm diameter components

• Front profile height: 10 mm

Test Procedures:

• Ensure the gauge and the P40 socket are thoroughly cleaned, free from dust, debris, or any damage that could compromise test accuracy.

• Confirm that the target plug has a 10 mm front profile height to ensure compatibility with the gauge.

• Align the gauge precisely with the internal configuration of the P40 socket and insert it smoothly into place.

• Utilize appropriate electrical testing equipment to conduct the continuity verification and record the measurement data.

• Evaluate the retention performance by observing the secure fit between the gauge and the socket’s retention mechanisms.

• Cross-check the test results against the requirements specified in par. 19.101 to determine compliance.

• Gently remove the gauge from the socket after completing the test to prevent wear or damage to either component.

Applications:

• Quality control inspections during the production of P40 sockets to ensure they meet electrical continuity and retention standards.

• Routine maintenance and performance checks of electrical devices equipped with P40 sockets in various settings.

• Compliance testing for electrical products integrated with the corresponding plugs and P40 sockets to satisfy regulatory demands.

• Laboratory research and durability assessments of P40 sockets to enhance product design and reliability.

• On-site testing of electrical installations featuring P40 sockets to guarantee safe and efficient operation in real-world use cases.

CEI 23-50 V4 Figure C13a