Product No: GNGPL-235C12

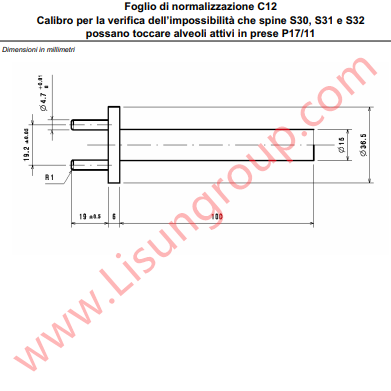

CEI-23-50 Foglio di normalizzazione C12 Calibro per la verifica dell’impossibilità che spine S30, S31 e S32 possano toccare alveoli attivi in prese P17/11 is designed in compliance with CEI 23-50. Its core function is to verify that S30, S31 and S32 plugs cannot make contact with the live sockets of P17/11 sockets, thus ensuring the safety and compliance of socket products and preventing potential electrical hazards caused by improper plug-socket matching. It is a professional testing tool for electrical component manufacturers and inspection institutions engaged in the production and quality control of household and similar electrical sockets.

Specifications

• Complies with the standard of CEI 23-50

• Features key dimensional parameters including ø15, 9.90ø, 2, 19a4.5

• Is dedicated to the compatibility verification between specified plug models and P17/11 sockets

• Is manufactured with high-precision processing to meet the strict dimensional tolerance requirements of electrical testing gauges

Test Procedures

• Prepare the to-be-tested P17/11 socket and the gauge, ensuring that both the socket and the gauge are free from damage, deformation and contamination that may affect the test results.

• Align the gauge with the socket according to the specified orientation and try to insert it into the P17/11 socket in a simulated plug insertion manner.

• Observe and check whether the gauge can touch the live alveoli of the P17/11 socket during the insertion and matching process.

• Record the test results, and judge whether the P17/11 socket meets the safety requirements based on whether the contact with live parts occurs as specified by the standard.

• After completing the test, clean and store the gauge properly to maintain its dimensional accuracy and service life for subsequent use.

Applications

• Quality inspection of P17/11 socket products in the production workshop of electrical socket manufacturers, to conduct batch sampling or full inspection of finished products to ensure compliance with safety standards.

• Third-party electrical product testing institutions use the gauge to carry out certification testing and compliance verification for P17/11 sockets on the market.

• R&D and design stages of socket products, to verify the rationality of the structural design of P17/11 sockets and ensure that the initial design can meet the anti-misplug and live-part isolation requirements.

• Daily quality supervision and spot check work of market supervision departments for household electrical socket products, to identify unqualified P17/11 socket products that may have potential safety risks.

CEI-23-50 Foglio di normalizzazione C12 Calibro per la verifica dell’impossibilità che spine S30, S31 e S32 possano toccare alveoli attivi in prese P17/11