Product No: GNGPL-3605

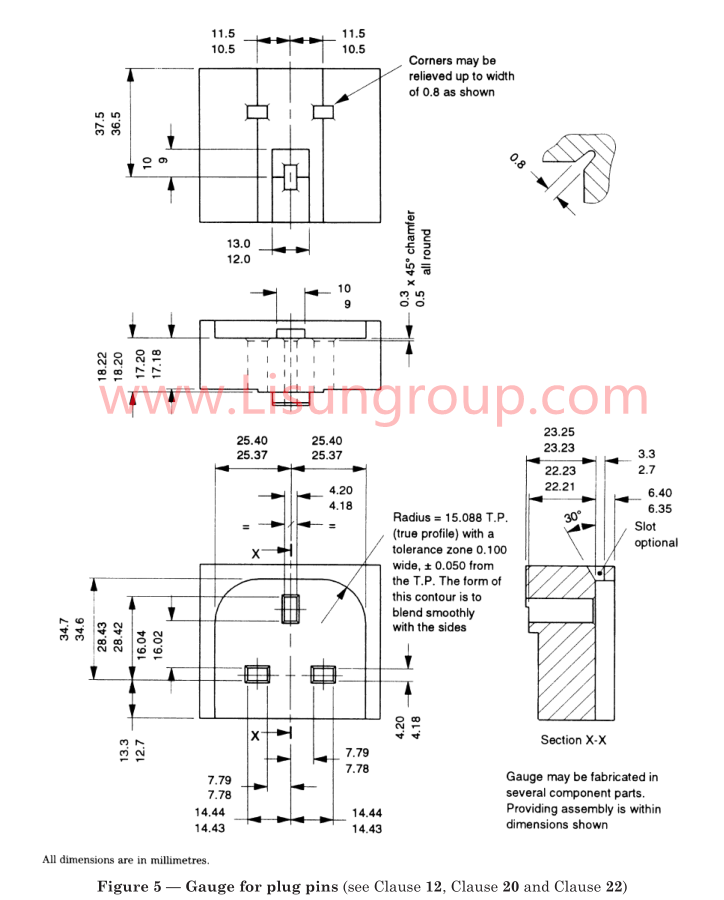

BS 1363-1 Figure 5 Gauge for Plug Pins is meticulously designed to assess the dimensional compliance and structural accuracy of plug pins in line with the rigorous requirements of BS 1363-1 Figure 5. It integrates high-precision manufacturing techniques and premium materials to ensure consistent, reliable test outcomes, serving as an indispensable tool for quality assurance, compliance verification, and R&D in the electrical components industry.

Specifications:

• Fully complies with the dimensional and performance criteria outlined in BS 1363-1 Figure 5

• Material hardness reaches over 50HRC, ensuring exceptional wear resistance and long service life

• Low thermal expansion coefficient maintains dimensional stability even under varying environmental temperature conditions

• Surface roughness meets standard specifications, preventing abrasion to tested plug pins during inspection

• All critical dimensions are calibrated in millimetres with tight tolerances to match standard requirements

• Incorporates precise locating features to ensure accurate positioning of plug pins during testing

• Structural design aligns with the mechanical performance demands of BS 1363-1 related clauses

Test Procedures:

• Prepare the plug pin specimens, ensuring they are free from surface defects, burrs, or deformations that could interfere with test results.

• Calibrate the gauge according to the standard’s pre-test requirements to confirm its dimensional accuracy and readiness for use.

• Position the plug pin specimen into the gauge’s designated locating structure, ensuring secure and correct alignment without applying excessive force.

• Inspect the fit between the plug pin and the gauge’s precision contours, checking for gaps or misalignments that indicate non-compliance.

• Measure key dimensional parameters of the plug pin using the gauge’s integrated reference points, recording data such as pin length, diameter, and relative position.

• Repeat the positioning and inspection process for at least three specimens from the same batch to ensure test repeatability.

• Compare all recorded test data against the dimensional limits specified in BS 1363-1 Figure 5 to determine compliance.

Applications:

• Compliance testing of 13 A plug pins to verify adherence to BS 1363-1 Figure 5 standards for market access and certification.

• In-line quality control on plug manufacturing production lines to identify non-conforming products at an early stage, reducing waste.

• R&D activities for plug pin design optimization, providing accurate dimensional feedback to enhance product performance and compliance.

• Third-party testing and certification services, supporting impartial verification of plug pin quality for manufacturers and regulatory bodies.

• Post-production batch inspection in electrical component factories to ensure consistent product quality across different production runs.

• Troubleshooting and quality auditing in the plug and socket industry, helping to identify root causes of non-compliance issues.

BS 1363-1 Figure 5 Gauge for Plug Pins