Product No: HCAI-2

The HCAI-2 High-Current Arc Ignition Test System is a LISUN test device designed specifically to evaluate the arc ignition resistance of insulating materials and solid combustible components in electrical and electronic equipment. It simulates the high-current arcing scenario generated by electrical equipment failures. By accurately striking an arc 200 times on the sample surface, the material is determined to ignite, thereby evaluating its resistance to high-current arc ignition. The HCAI-2 integrates a stable arc generation system, a precise arc counting module, and a reliable combustion monitoring device, efficiently replicating standard test conditions. It is widely used in the R&D, production, and quality inspection of lighting, low-voltage electrical appliances, household appliances, information technology equipment, and other industries. It also meets the performance assessment needs of the insulation materials and engineering plastics industries, making it a crucial testing tool for ensuring the safe operation of electrical and electronic products and preventing electrical fires.

Standard:

| Standards NO. | Standards Name |

| IEC 60947.1:2020(Annex M Figure M.2) | Low-voltage switchgear and controlgear – Part 1: General rules |

| IEC 60730-1:2013(Annex D.1.10) | Automatic electrical controls for household and similar use – Part 1: General requirements |

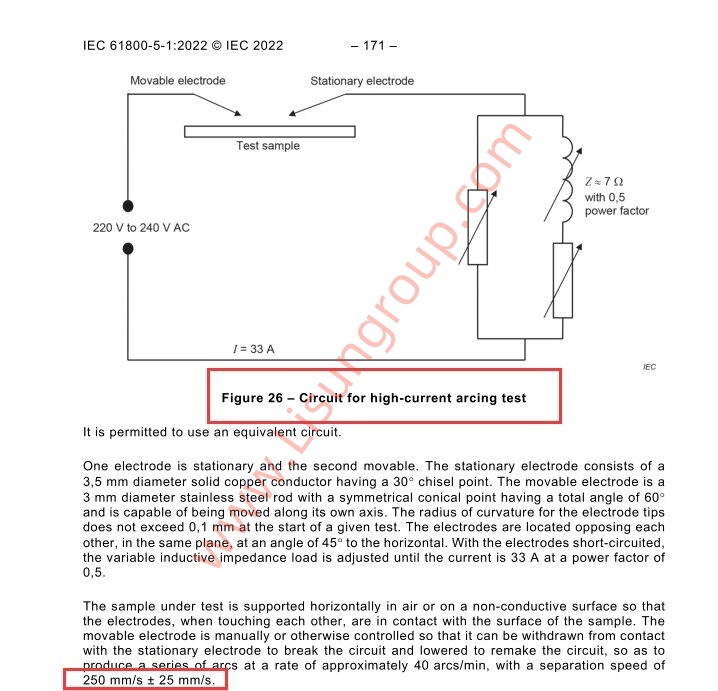

| IEC 61800-5-1:2022(Clause 5.2.5.2 Figure 26) | Adjustable speed electrical power drive systems – Part 5-1: Safety requirements – Electrical, thermal and energy |

| UL 746A:2023(Clause 33) | Standard for Polymeric Materials – Short Term Property Evaluations |

| GB/T 14048.1-2023(附录 M 图 M.2) | 低压开关设备和控制设备 第 1 部分:通用要求 |

| GB 14536.1-2008(附录 D.1.10) | 家用和类似用途电自动控制器 第 1 部分:通用要求 |

Specifications:

| Specifications | Detailed Parameters |

| Power meter | 40A Power Meter: 1. Real-time display of current, voltage, power, frequency, and power factor; 2. Function: With over-threshold alarm function |

| Arc ignition times | 0~200 times (settable, automatic counting, accuracy ±1 time), default 200 times |

| Arc striking current | 33A±5A (adjustable), adapted to the arc energy requirements of the standard |

| Arc striking power factor | COSφ 0.5±0.05 (adjustable), supporting power factor matching in different test scenarios |

| Arc striking speed | 250mm/s±25mm/s, ensuring stable arc intensity |

| Arc ignition frequency | 40 times/min (adjustable), arc striking interval can be adjusted according to standard requirements |

| Adjustable power parameters | 1. Current: 0~40A (adjustable); 2. Voltage: 125~150V (adjustable); 3. Power factor: 0.3~0.9 (adjustable) |

| Electrode supply voltage | AC 220V, matching the electrode arc striking requirements |

| Electrode material | Static electrode: copper; moving electrode: stainless steel |

| Electrode size | 1. Static electrode: diameter ф3.2mm~ф3.5mm, 30° chisel end; 2. Moving electrode: diameter ф3.0mm, 60° cone end |

| Electrode angle | 45° to the horizontal plane, in line with the requirements of the standard appendix diagram |

| Sample size | 130mm*13mm*(2~12) mm, suitable for most electrical and electronic components and material samples |

| Sample clamping method | Horizontal fixation, compatible with sheet and block specimens, positioning accuracy ±0.5mm |

| Combustion monitoring | 1. Monitoring method: High-definition industrial camera + flame sensor dual monitoring; 2. Recording content: Automatically records ignition time and arcing times, and supports video playback of the test process |

| Smoke exhaust system | Equipped with a fan smoke exhaust system to quickly exhaust the smoke generated by the test and ensure a clean test environment |

| Lighting system | Built-in LED lighting ensures clear visibility of the test process |

| Key component brands | The electrical parts (such as contactors and circuit breakers) adopt world-renowned brands such as Schneider to ensure equipment reliability |

| Test environment conditions | Test environment conditions: 1. Temperature: 15°C to 35°C; 2. Relative humidity: 45% to 75%; 3. Atmospheric pressure: 86kPa to 106kPa |

| Combustion chamber specifications | Independent combustion chamber, volume ≥ 0.5m³, meeting safety protection requirements |

| Security protection | 1. Arc protection: fully enclosed arc shield (to prevent arc splashing); 2. Electrical protection: overcurrent protection, overload protection, leakage protection; 3. Emergency control: emergency stop button, test chamber door interlock (opening the door will interrupt the test) |

| Body material | High temperature spray-coated steel structure, high temperature resistance, corrosion resistance, adaptable to long-term high temperature testing environment |

| Operation Display | Self-developed large LCD touch screen + clear indicator light + remote control |

Operation:

1. Electrical and Electronic Products Industry

1.1 Equipment and Component Testing

• Lighting Equipment: Test the insulation housing of LED drivers and the plastic components surrounding lamp terminals to verify that they do not ignite when exposed to arcing, thereby preventing lamp fires.

• Low-voltage Electrical Equipment: Evaluate the insulation housings and terminal insulation sleeves of circuit breakers and contactors to ensure arcing does not ignite components, thereby ensuring the safety of low-voltage power distribution systems.

• Household Appliances: Inspect the motor insulation and control panel plastics of washing machines and refrigerators to prevent equipment damage caused by arcing due to internal circuit faults.

• Information Technology Equipment: Verify that the insulation materials of power modules and combustible components surrounding the motherboard of computer hosts and servers meet the safety requirements of GB/T 4943.1-2022.

1.2 Electrical Connector and Accessory Testing

• Tests the insulation housings of terminal blocks, plugs and sockets, and cable insulation (e.g., PVC, XLPE) to ensure arcing does not ignite the connectors and prevent fires in the wiring.

2 Insulation Materials and Engineering Plastics Industry

• Evaluates the arc ignition resistance of materials such as insulating paper, epoxy glass cloth, PA66, and PC. This provides a basis for selecting components for electrical and electronic products, optimizes material flame retardant formulations, and enhances overall product safety.

3. R&D and Quality Inspection

• Corporate R&D departments: During the new product design phase, this system verifies the arc resistance of insulation materials and components, helping to proactively mitigate safety hazards.

• Third-party testing organizations: SGS, CQC, UL, and other organizations use this equipment to conduct product compliance testing based on standards such as GB/T 14048.1-2023 and IEC 62368-1:2018, issuing authoritative test reports and helping products obtain market access certification.

IEC 61800-5-1:2022 Clause 5.2.5.2 Figure 26