Product No: GNGPL-235C104B

This CEI 23-50 V4 Figure 104b Gauge is a high-precision testing instrument compliant with the CEI 23-50:2007 Standard, specifically designed to verify electrical continuity and retention performance of S17 plugs in P40 sockets as specified in paragraph 19.101. It offers two variants with front profile heights of 10 mm and 12 mm to meet diverse testing requirements, featuring strict dimensional control and structural reliability. Engineered to adhere to rigorous standard specifications, it serves as a critical tool for ensuring the safety, functionality, and compliance of electrical plug-and-socket assemblies.

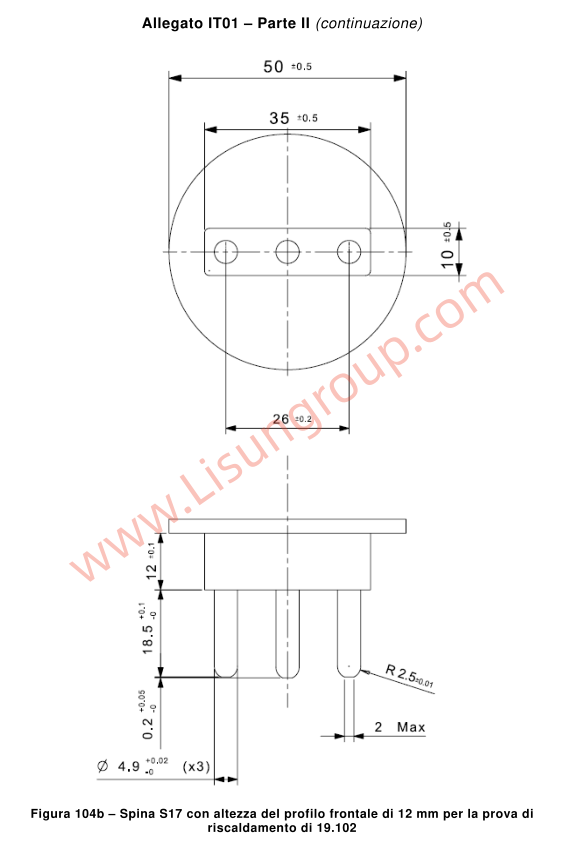

Specifications:

• Front profile height options: 10 mm and 12 mm

• Dimension with tolerance: 50 ±0.5 mm

• Dimension with tolerance: 35 ±0.5 mm

• Dimension with tolerance: 26 ±0.2 mm

• Radius specification with precision: R2.5 : 0.01

• Maximum value: 2 Max

• Diameter with tolerance (3 units): ø4.9 ±0.02 mm (interpreted from “ø4.9 40.02”)

Test Procedures:

• Prepare the test environment to align with the operational requirements outlined in the CEI 23-50:2007 Standard.

• Select the appropriate gauge variant (10 mm or 12 mm front profile height) based on the test object and application scenario.

• Securely mount the P40 socket and S17 plug in the test fixture, ensuring proper alignment with the gauge.

• Initiate the electrical continuity test following the protocols specified in paragraph 19.101 of the standard, measuring and recording relevant electrical parameters.

• Conduct the retention performance test by applying the specified force (6N and 8N as applicable) and verifying the socket’s ability to retain the plug securely.

• Monitor the gauge’s positional stability and dimensional consistency throughout the testing process to ensure data accuracy.

• Conclude the test after completing all required procedures, and analyze the results to determine if the plug-and-socket assembly meets the standard’s compliance criteria.

• Document the test data, including dimensional measurements, continuity readings, and retention force results, for quality records.

Applications:

• Verification of electrical continuity and retention performance for S17 plugs and P40 sockets in compliance with CEI 23-50:2007 Standard (paragraph 19.101).

• Quality control and compliance testing for manufacturers producing electrical plug-and-socket assemblies adhering to CEI specifications.

• Laboratory-based performance evaluation of electrical components to ensure safety and functional reliability.

• Calibration and validation of testing equipment used in the production and inspection of plug-and-socket systems.

• Regulatory compliance testing for products seeking market access in regions where the CEI 23-50:2007 Standard is mandatory.

• R&D testing for the development and optimization of P40 socket and S17 plug designs, ensuring alignment with industry performance benchmarks.

• Routine inspection and maintenance testing of electrical components in industrial, commercial, and residential applications.

CEI 23-50 V4 Figure 104b Gauge